Customized colloidal grout mixing and pumping unit shipped to Peru

2025-07-25 18:37:42

Today, a fully electric-hydraulic driven colloid grouting machine from Leadcrete Equipment was officially loaded and shipped to Peru. The grout equipment is deeply benchmarked against the international benchmark product ChemGrout CG-600 series, and customized and upgraded to meet the core needs of customers such as "efficient mixing, high-pressure transportation, and multi-material adaptation", marking that China's high-end grouting equipment has achieved technological breakthroughs and brand breakthroughs in the South American market.

The colloidal grout mixing and pumping unit delivered this time will serve a large copper mine tailings reinforcement project in Peru and a subway tunnel grouting project in Lima. The customer clearly proposed four technical standards:

1. Colloidal mixing accuracy: high-speed shearing is required to achieve nano-level dispersion of materials such as cement, bentonite, and fly ash to avoid particle agglomeration;

2. Continuous high-pressure transportation: under complex geological conditions (such as fault fracture zones), grouting must be stabilized at a flow rate of 76L/min and a pressure of 18bar;

3. Full process integration: integrated crushing, mixing, stirring, and pumping functions to reduce the number of on-site equipment and manual operation risks;

4. Power redundancy design: supports electric-hydraulic and diesel-hydraulic dual modes to adapt to the construction environment in remote areas of Peruvian mining areas without stable power grids.

Our R&D team spent 1 month to tackle the problem and finally delivered this grout mixing and pumping unit to achieve the following technical breakthroughs:

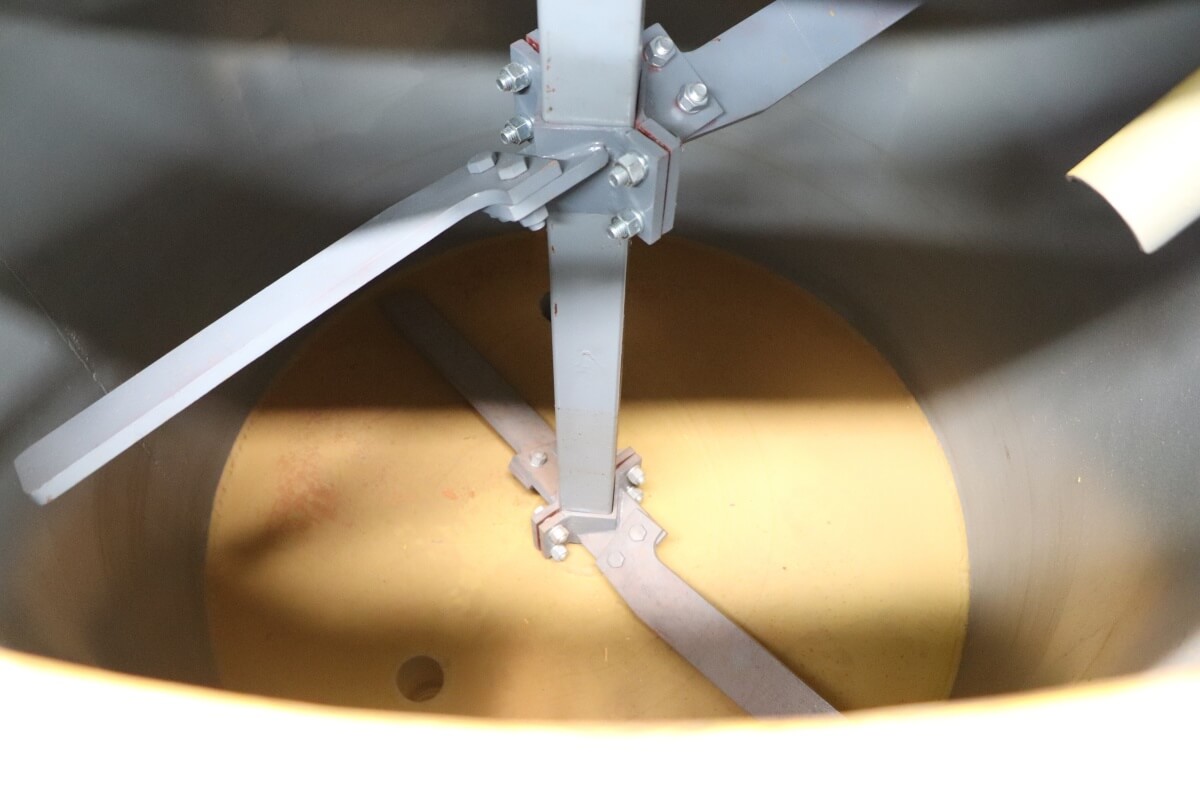

1. Colloid-grade mixing system: 2000RPM high-speed shearing + intelligent bag breaking

Mixing capacity: 8 cubic feet (220L) and 13 cubic feet (368L) are available to meet the needs of different engineering quantities;

Core configuration:

Double-layer paddle high-speed shearing machine: The speed reaches 2000RPM, which can refine the powder particles to less than 10μm, significantly improving the fluidity and early strength of the slurry;

Fully automatic bag breaker: Integrated vibrating screen and negative pressure suction device, which can handle 25kg bagged powder at a time, and the bag breaking efficiency is 80% higher than that of traditional manual work;

Mixing guarantee: Equipped with a 13 cubic foot (370L) storage tank with a stirring paddle to prevent slurry precipitation and segregation.

2. Progressive cavity pump: 76L/min@18bar stable outputUsing a single-screw progressive pump body, the volume change of the rotor and stator realizes pulsation-free transportation to avoid slurry stratification;

Equipped with a pressure compensation valve and a variable frequency speed regulation system, it can automatically adjust the flow and pressure according to the formation resistance to ensure the uniformity of grouting;

Material upgrade: The pump body flow parts are made of duplex stainless steel 2205, which has a wear resistance three times higher than that of ordinary alloys and a service life of more than 5,000 hours.

3. All-terrain integrated design: free switching of electric-hydraulic dual powerModular integration: the mixer, mixing tank and pumping unit are integrated into a 4.5m×2.2m steel skid, with a total weight of ≤4.8 tons, which can be transported by standard containers;

Power solution:

Electric mode: adapted to 380V/50Hz three-phase electricity, power of 37kW, energy consumption is 40% lower than that of diesel drive;

Diesel mode: equipped with a 42kW diesel engine to drive the hydraulic pump, the continuous operation time exceeds 12 hours, meeting the emergency needs of the mining area;

Intelligent control: equipped with a 7-inch touch screen, real-time display of pressure, flow, speed and other parameters, and supports fault self-diagnosis and remote upgrade.

According to the data of the Peruvian National Engineering Association, the annual grouting project volume in the mining and infrastructure fields of the country exceeds US$500 million, but high-end grout equipment has long relied on imports from Europe and the United States. The delivery of Chinese equipment this time not only fills the gap in the local market in the field of colloid grouting technology, but also provides new choices for South American customers with the strategy of "customization + high cost performance". If you have the same customized colloidal grout mixing and pumping unit requirements, you can directly contact us through email address: sales@leadcrete.com

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS