► Description:

Spray seeding is more and more applied in road greening. The application of seeding spraying technology in vegetation restoration and slope protection project. Soil spraying seeder involves in planting permanent vegetation, spraying slurry, slope protection,

grassing and erosion prevention.

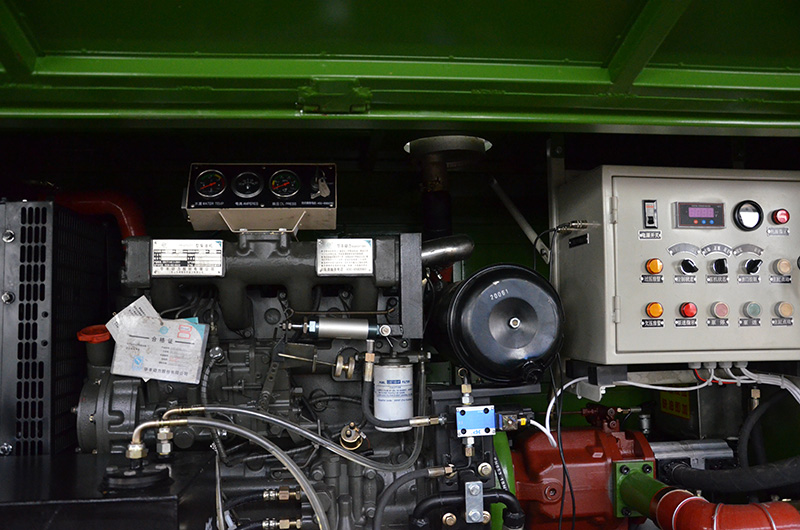

Soil spraying seeder driven by single diesel, electronic control, easy operation, especially suitable for outdoor conditions, applicable to all kinds of rock slope, hard soil, poor soil, acidic soil, arid zones, clay soil and coastal dam etc.

► Features:

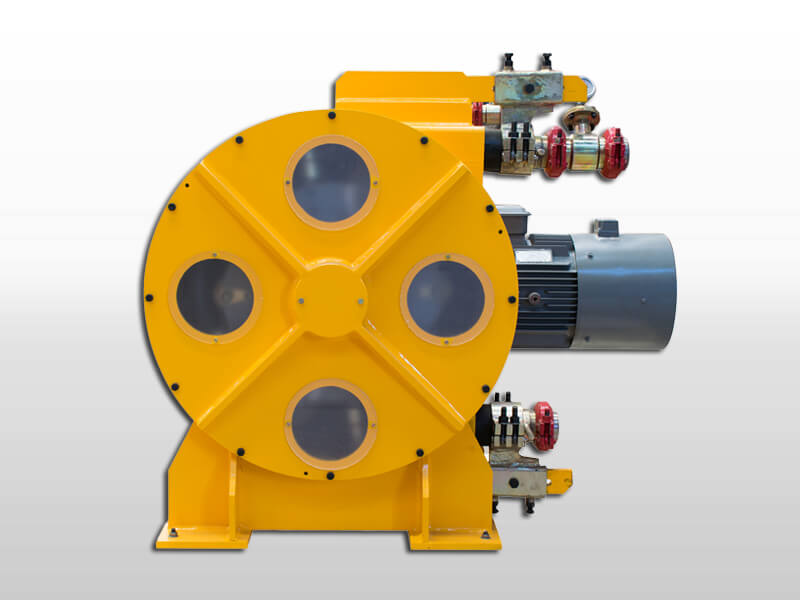

1. High efficiency : using hydraulic pumping method, high reliability, stable conveying ability;

2. long conveying distance , up to 650 m horizontally,160 m vertically;

3. injection quantity is continuously adjustable with variable piston pump , jet speed can be adjusted freely;

4. machine parts consumption is very low , the machine wearing parts life is not less than 2000 cubic meters jetting ability;

5. combined with automatic centralized lubrication system, realizing effective control for the amount of grease filling and filling time, extending life of wear parts;

6. humanized product design, more convenient operation, more simple maintenance, reliability has been effectively guaranteed;

7. Advanced technology, it even works for mud materials which have poor mobility, no blocking, and no stopping, well adaptation of various materials, big output pressure;

8. blades mixing and circular spray, are powerful enough to ensure the spraying mixture in the planting process is in fully suspended and fully mixed stated, evenly emitting the mixture of raw materials at one time;

9. This machine has wide usage, not only can be applied in spraying planting for soil improvement work. This machine can emit slurry materials with big proportion, high and super concentration;

10. Our slope soil spraying machine can also be used in plain concrete and fiber reinforced concrete conveying in various construction sites.

| Model | Unit | LKP-15SR | LKP-25SR |

| Max. Injection capacity (theory) | m³/h | 15 | 25 |

| Max. pumping pressure | Mpa | 10 | 14 |

| Max. vertical conveying distance (theory) | m | 120 | 160 |

| Max. horizontal conveying distance (theory) | m | 500 | 650 |

| Distributing valve form | S valve | S valve | |

| Max. Aggregate size | mm | 30 | 30 |

| Slump | cm | 12~23 | 12~23 |

| Rebound Rate | % | less than 15 | less than 15 |

| Working dust density (machine) | mg/m³ | less than 10 | less than 10 |

| Transporting cylinder diameter * stroke | mm | 140*1000 | 140*1000 |

| Diesel engine power | kw | 50.6 | 61.6 |

| Rated rotating speed | rpm | 1800 | 1500 |

| The hydraulic oil tank volume | L | 350 | 350 |

| The fuel tank volume | L | 60 | 60 |

| Feeding height | mm | 1200 | 1200 |

| Overall dimension | mm | 4550*1680*1950 | |

| Weight | kg | 2850 | 3000 |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS.jpg)

.jpg)

.jpg)

.jpg)

.jpg)