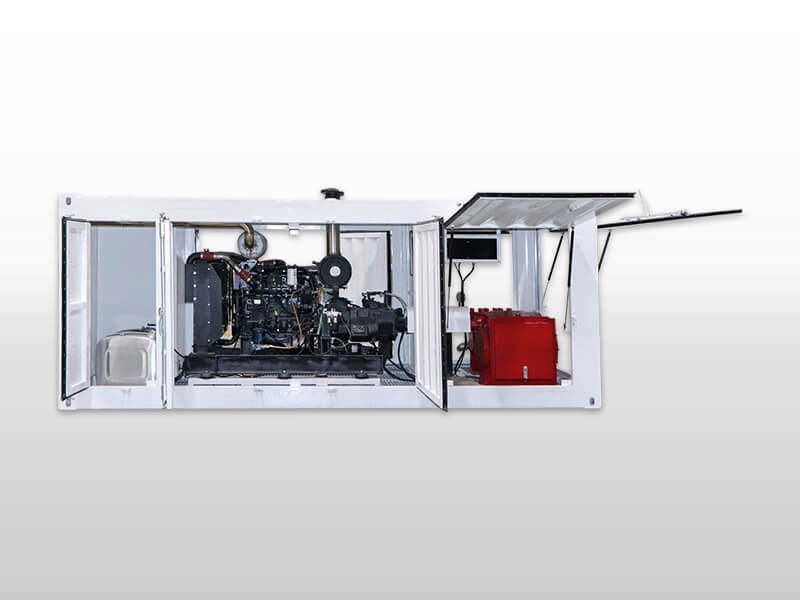

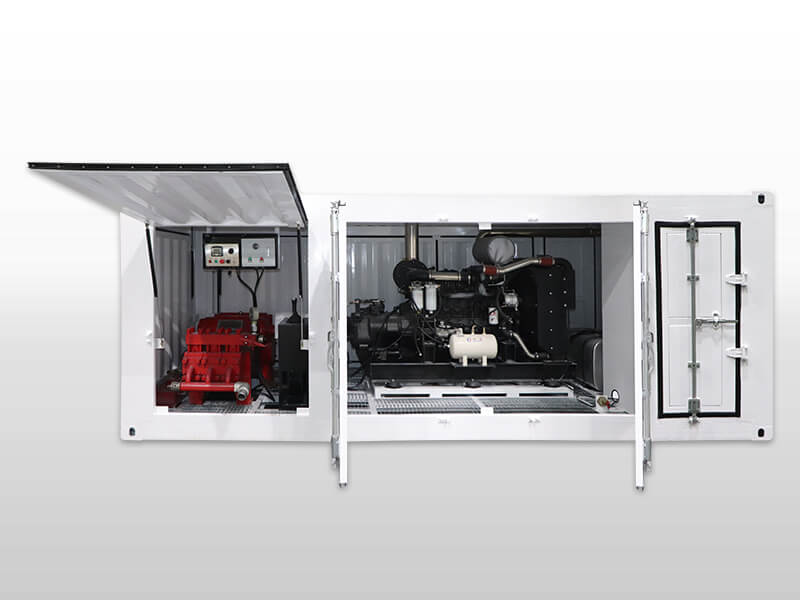

LGP250/450-250D diesel grout pump for jet grouting is a horizontally oriented, three-cylinder, single-acting reciprocating pump meticulously designed and manufactured by our company. The jet grouting pump is mainly used in engineering scenarios that require high-pressure grouting, such as high-pressure jet pile construction, where the slurry is injected into the stratum through high pressure to achieve the purpose of foundation reinforcement and anti-seepage treatment. This pump is engineered to fit seamlessly within a standard 20ft container, facilitating effortless transportation to any worksite.

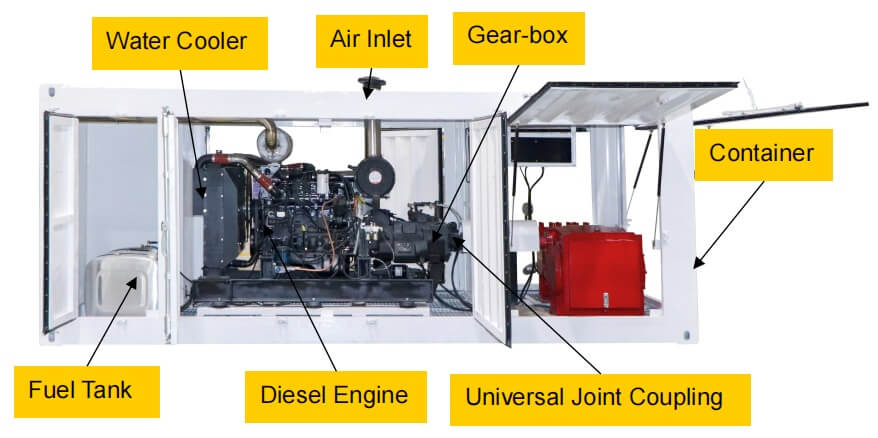

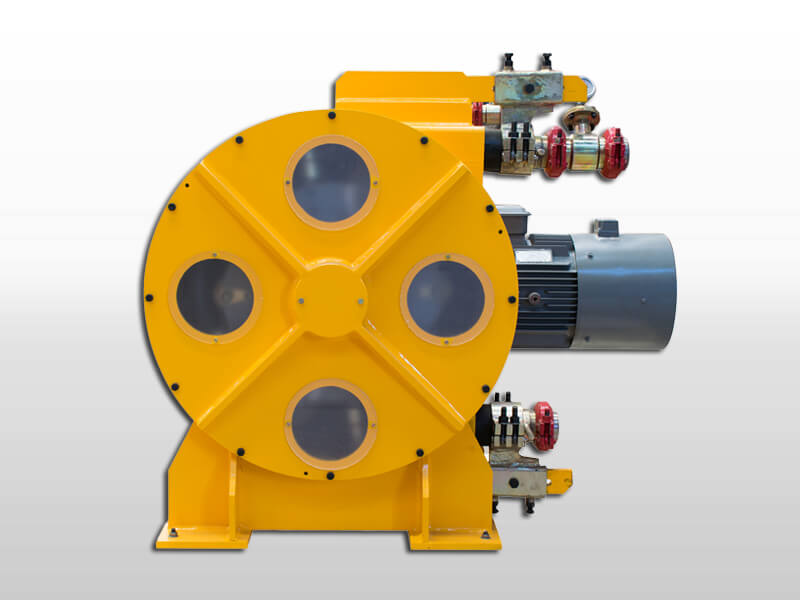

Diesel grout pump for jet grouting consists of several key components, including a robust 260HP diesel engine serving as the power source, a reliable clutch, a precision-engineered gearbox (Eaton FAST model), a universal joint coupling, and the high-pressure pump itself. The gearbox is equipped with four gears and offers continuous variable speed adjustment to meet diverse operational demands.

Building upon the conventional two-speed configuration, the high-pressure jet grouting pump employs a tile-type transmission system, a significant improvement over the needle roller transmission commonly found in similar domestic products. This innovative design mitigates the risk of frequent damage, thereby enhancing the operational lifespan of the pump's power end. While the tile-type transmission may experience normal wear and tear between the tiles and the shaft, it ensures that the pump remains operational, preventing project delays caused by sudden component failures.

►Working Principle:

The high pressure diesel jet grouing pump is a horizontal three-cylinder single-acting reciprocating pump, which uses the camshaft to drive the piston to reciprocate in the cylinder. When the piston moves downward, the fuel enters the pump chamber through the suction port; when the piston moves upward, the fuel is pressurized and output through the oil outlet valve, and the oil suction and pressure cycle is realized through the change of the sealed volume, so that the fuel is pressurized and supplied to the high-pressure injection nozzle.

►Application:

LGP250/450-250D is a high-pressure diesel grout pump designed for jet grouting applications, delivering robust high-pressure power to reinforce and stabilize weak foundations in new constructions such as buildings, highways, high-speed railways, and underground railways. It is equally effective in remedial projects, including addressing uneven settlement in aging structures, constructing deep prevention curtains, erecting soil-retaining cofferdams, and preventing mine leakage. The pump also supports specialized tasks like well casing protection, slope anchoring, and other critical applications in reservoir dams and underground engineering.

►Features:

1. Dynamical System

Engine: 260HP Cummins diesel engine for high efficiency and reliability, ideal for construction sites.

Safety: Low-voltage operation enhances safety.

Factor of Safety: Engineered for robust performance and durability.

2. Transmission System

Speed Range: 4-speed continuously variable transmission (CVT) for wide-range speed control and fast response.

Universal Joint: Retractable universal joint coupling compensates for rotational irregularities.

Tile Transmission: Extends the lifespan of the pump’s power end.

Adjustable Performance: Grouting pressure (up to 450 bar) and displacement (up to 250 L/min) are steplessly adjustable.

3. Plunger Design Grout Pump

Triple-Cylinder Configuration: Three cylinders (75mm diameter, 100mm stroke) ensure stable pressure and flow.

Material: Special steel quenching treatment for enhanced durability.

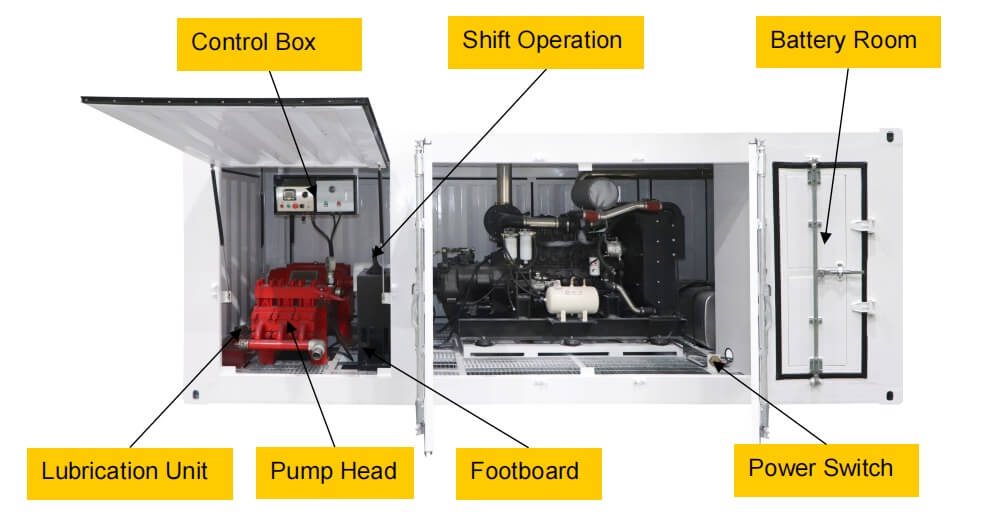

Pump Head: Forged from a single section for structural integrity.

4. Diaphragm Valve

Safety Mechanism: Shears when inlet pressure exceeds the opening threshold, releasing pressure to prevent overloading.

5. Operating System

Automation: High degree of automation for simplified measurement and operation.

User-Friendly: Intuitive controls for ease of use.

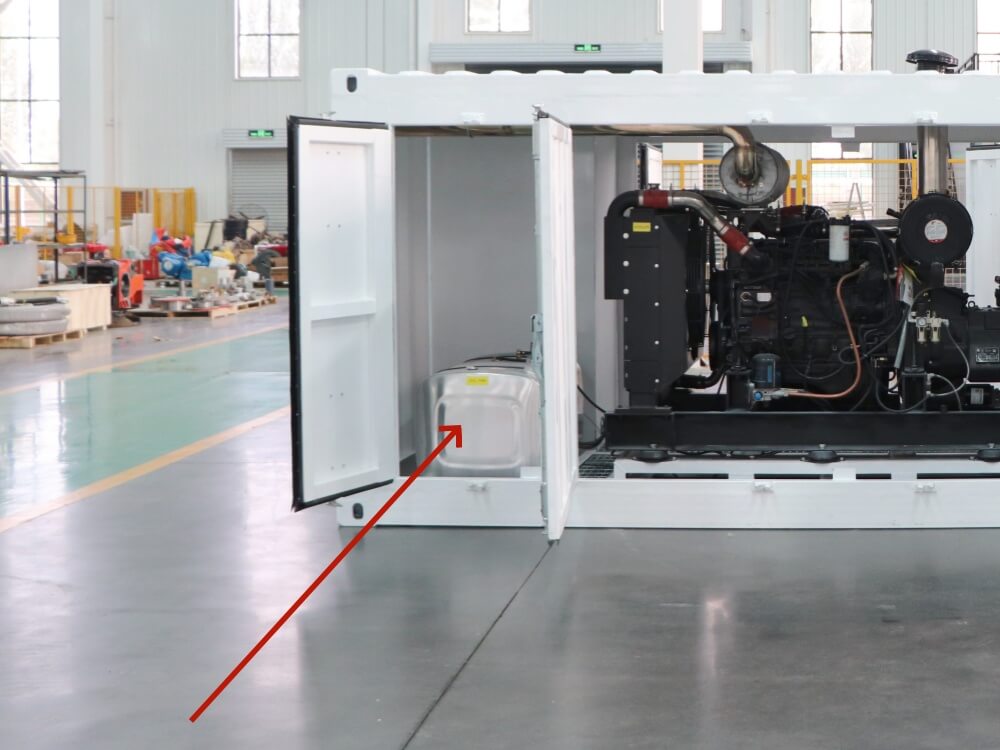

6. Container Structure

Dimensions: 5,700mm (L) × 2,280mm (W) × 2,190mm (H).

Design: Based on standard container specifications for portability.

Safety: Anti-slip steel grid plates in empty spaces for worker safety.

7. Operational Efficiency

Ease of Use: Simple operation and maintenance.

Lighting: Equipped with ceiling lamps to illuminate work areas.

1. Dynamical system: diesel engine driven, high efficiency, more suitable for the construction site.

2. Transmission system: 4-speed continuously variable transmission, wide speed range, high transmission efficiency.

3. Plunger: 3-cylinder alternating motion ensures stability of pressure and flow

4. Operating system: convenience, high degree of automation, simple measurement and operation.

5. Can be placed directly in the 20ft cabinet.

|

Model |

LGP250/450-250D jet grouting pump |

||

|

Diesel engine

|

Type |

QSF6.7-260C Cummins |

|

|

Power |

HP |

260 |

|

|

Max. speed |

r/min |

2200 |

|

|

Gear-box |

Type |

EATON FASE |

|

|

Speed |

4 |

||

|

Control |

Level |

||

|

Main pump |

Type |

GP250/450 |

|

|

Form of action |

Reciprocating single acting plunger type |

||

|

Number of Plungers |

Piece |

3 |

|

|

Plungers |

mm |

Φ75 |

|

|

Output @ Pressure |

L/min@bar |

250@450 |

|

|

Inlet diameter |

mm |

64 |

|

|

Outlet diameter |

mm |

32 |

|

|

Note: |

|||

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS