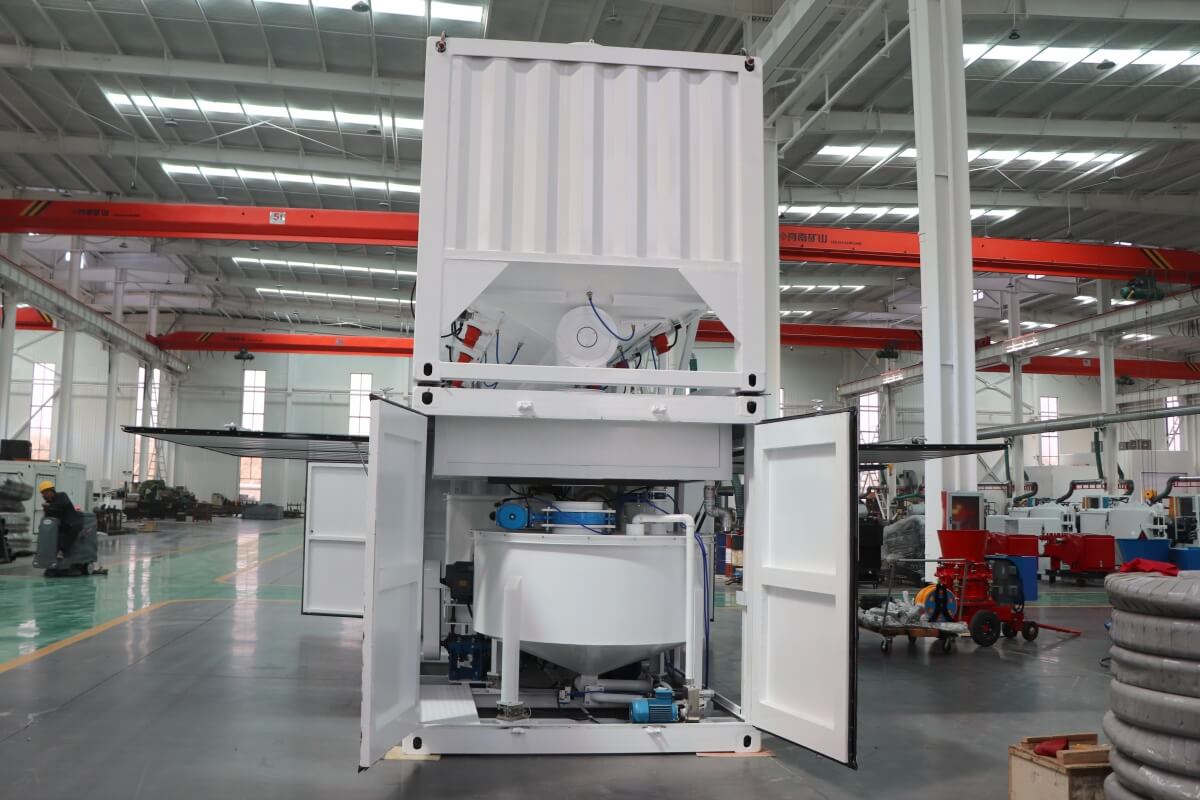

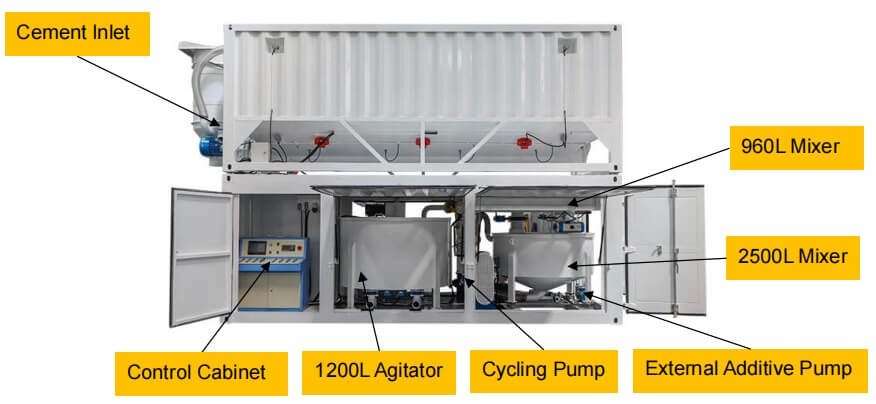

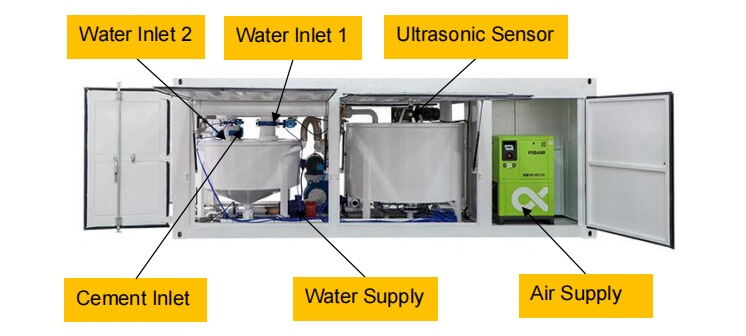

The LMA30 automatic cement mortar grout mixing plant is specifically developed to produce high-quality cement grout by vigorously mixing water and cement powder under turbulent conditions. Alternatively, it can blend water with bentonite powder to create a viscous bentonite slurry, ideal for applications requiring plastic mud. The plant is further capable of preparing ternary or quaternary compound mixtures, accommodating configurations with one or two liquid components paired with a single solid component (per screw conveyor). Once mixed, the cement grout or bentonite slurry is transferred to downstream units, tailored to the specific requirements of the geotechnical machinery in use.

The HCS17B horizontal cement silo is engineered to conform to the dimensions of a standard 20-foot shipping container, enabling direct storage within the container frame. This design significantly reduces shipping expenses by eliminating the need for specialized transport.

► Application:

The main application areas of automatic cement mortar grout mixing plant are:

1. Geotechnical Engineering

Jet grouting, compaction grouting, and soil mixing for foundation reinforcement.

Seepage control in tunnels, basements, and retaining walls.

2. Civil Infrastructure

Production of waterproofing grouts for underground structures (e.g., subway tunnels, parking garages).

Repair and rehabilitation of damaged concrete structures.

3. Mining & Tunneling

Stabilization of excavated surfaces and prevention of groundwater ingress.

Production of bentonite-based drilling muds for trenchless construction.

4. Environmental Remediation

Sealing of contaminated soil layers or landfill liners.

Injection of cementitious grouts for solidification/stabilization of hazardous waste.

► Features:

Cement silo configuration and quantity:

1. Dust removal (1)

2. Pressure relief valve (2)

3. Screw Conveyer-11Kw (1)

4. OLI-WOLONG Vibrator-1.3Kw (6)

5. Air disc-vibrational fluidization and jet fluidization(10)

6. Upper recalling dipstick-damped rotation controller (2) and lower recalling dipstick-damped rotation controller (2)

Automatic cement mortar grout mixing plant features:

1. Up to 5mm particle size

2. Automatic bentonite grout mixing plant with cement silo can be placed directly in the 20ft cabinet

3. Two modes of operation: fully automatic mode and manual mode

4. The preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component

5. Main pipeline valves are all pneumatic valves

6. Mixture, cycling pump and agitator have an automatic cleaning function

7. Cement can be added by cement silo or screw feeder automatically

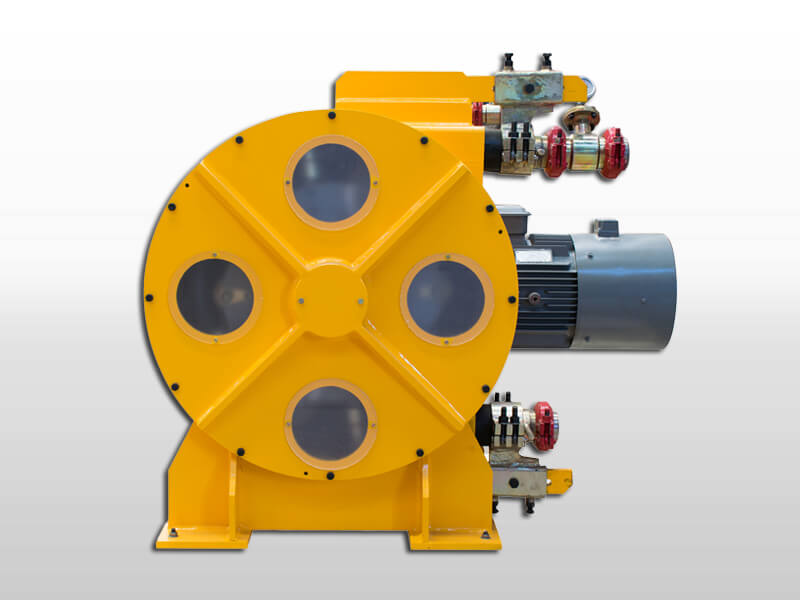

8. High-speed colloidal grout mixer

9. Equipped with some ceiling lamp, for illuminating the different working areas

10. Easy to operate and maintain

|

LMA30 Automatic cement mortar grout mixing plant specification: |

|||

|

1. Two modes of operation: fully automatic mode and manual mode mixing plant. |

|||

|

HCS17B Cement Silo |

|||

|

Volume |

17m³ |

Conveying |

60t/h |

|

Inlet Dia. |

100mm |

Outlet Dia. |

325mm |

|

Main power |

11Kw |

Power supply |

380V, 50Hz |

|

LMA30 Mixing Plant |

|||

|

Mixer |

Agitator |

||

|

Capacity |

1200L |

Capacity |

2500L |

|

Flow |

50L/s |

Speed |

25r/min |

|

Max. output |

30m³/h |

Level sensor |

Ultrasonic sensor |

|

Power |

15Kw |

Power |

3.0Kw |

|

Air supply system |

Water supply system |

||

|

Flow |

540-1350L/min |

Water tank volume |

960L |

|

Pressure |

0.8MPa |

Flow@lift |

11.11L/s@20m |

|

Power |

7.5Kw |

Power |

5.5Kw |

|

External additive supply system |

Flow@lift |

2.8L/s@18m |

|

|

Power |

1.5Kw |

||

|

Power supply |

380V, 50Hz |

||

|

Note: |

|||

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS

.jpg)

.jpg)