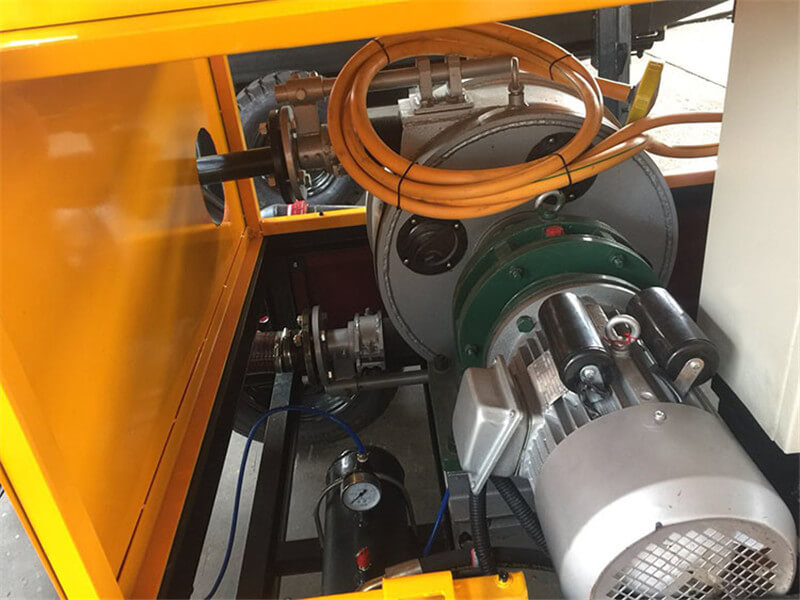

LF10B foam concrete machine puts a screw conveyor, a concrete mixer, a foam generator and a hose pump 4 parts in one, adopts advanced control technology, can exactly adjust foam cement density; it also meets different density of foam concrete manufacturing. The capacity is 10m3/h, can directly put on the truck for working.

It is easy to operate, low cost and mobile, with continuous material feeding and water supply system, high pumping height and low power requirement.

► Application:

Lightweight foam concrete machine is applied for roof insulation constructions. The foam material used in roof insulation is with warm keeping, heat insulating function, it’s effect is 20-30 times the ordinary material, which keeps the room temperature of top floor the same as other floors, warm in winter and cool in summer.

LF10B lightweight foam concrete machine can be used in producing various specifications of cement foam board, cement foam bricks and external wall insulation material. Also applied for insulation, moisture proofing, anticorrosion of water, heating and transmission oil pipeline, insulation of low temperature cold store and refrigerated depot section, can also be used in filling tunnel and mine internal voids etc.

► Features:

1. Frequency converter: Can exactly adjust foam cement density.

2. Static mixer : Reduce the ratio of foam loss and guarantee the quality of the foam concrete.

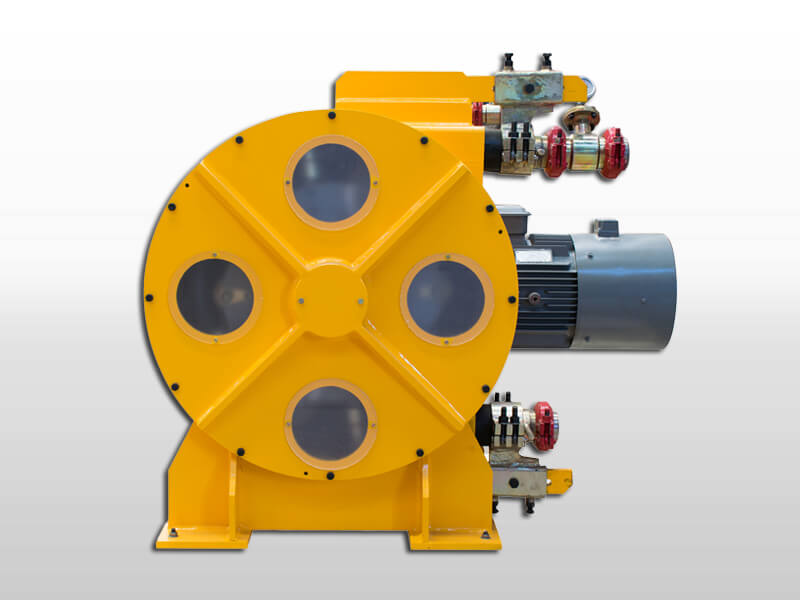

3. Hose pump: Compared with screw pump and piston pump, the hose pump has almost no damage to the performance of foamed concrete.

4. Screw conveyor: Time-saving and labour-saving, very convenient to use.

5. Dust cover: Protect working people from dust, keep healthy.

| Model | LF10B |

| Max. theoretical output(m³/h) | 10 |

| Motor power(kw) | 9.8 |

| Theoretical vertical conveying height(m) | 10 |

| Theoretical level transmission distance(m) | 50 |

| Mixer tank capacity(L) | 350 |

| Feeder size(mm) | 2990*760*830 |

| Overall dimension(mm) | 2390*1490*1440 |

| Total weight(kg) | 1000 |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS