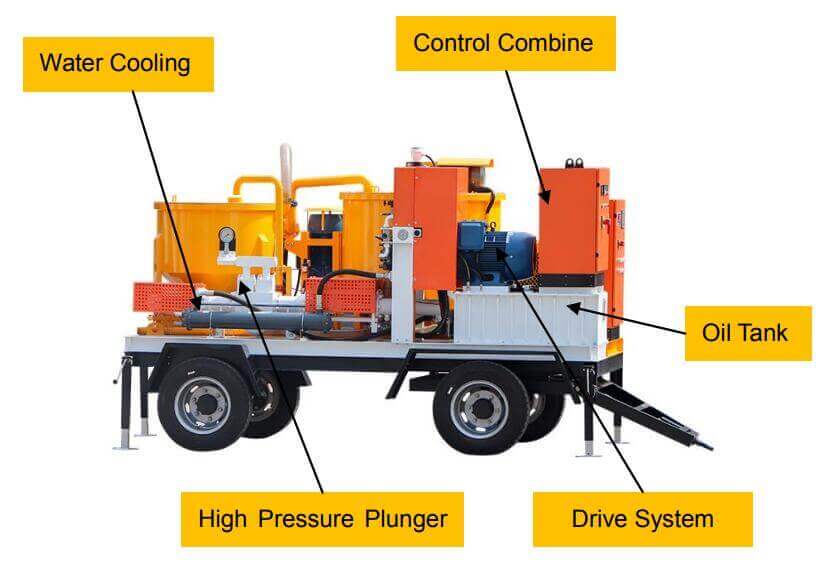

LGP400/1000/95/165DPL-E/A Fully automatic mobile grouting plant is integrated with a screw feeder, a mixer, an agitator and a horizontal hydraulic grout pump. It is mainly used to be made such as cement slurry or bentonite slurry, etc., for injecting in the sub-soil for soil consolidation, piling, or even for long transport of material.

Details Instructions of LGP400/1000/95/165DPL-E/A Fully automatic mobile grouting plant:

► Application:

Compared with the traditional grout plant unit, fully automatic mobile grouting plant has several advantages:

High-speed, high-shear colloidal mixer causes a vortex flow to ensure that mix quickly and evenly;

Two pieces of high pressure plungers to stabilize the consistency of the grouting flow;

Grouting pressure and displacement are step-less adjustable;

Added the automatic operation mode, which greatly improves the working efficiency.

Besides, compact size and easy to operate. And it also takes up a small space.

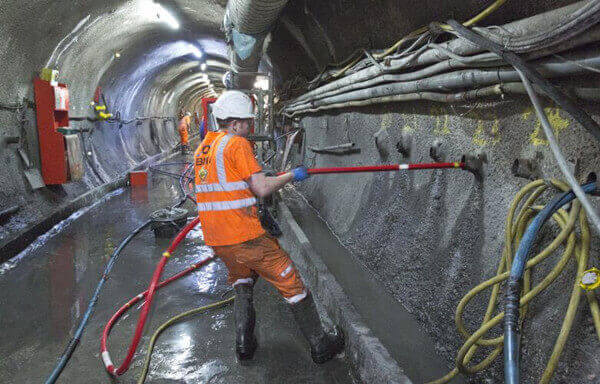

Therefore, this automatic grouting plant is widely used in mines, tunnels, culverts, subways, hydropower projects, underground projects, etc.

► Features:

Mixer station features:

1. 3 sets of stable weighing modules.

2. Lower charging material height for the mixer.

3. High-speed colloidal grout mixer.

4. Smoothly outflow slurry through the pneumatic pinch valve.

5. Precision of the ultrasonic liquid level meter.

6. PLC machine control.

Visualization interface.

Simple operation interface.

Manual mode and fully automatic mode.

Multiple formulations can be set up.

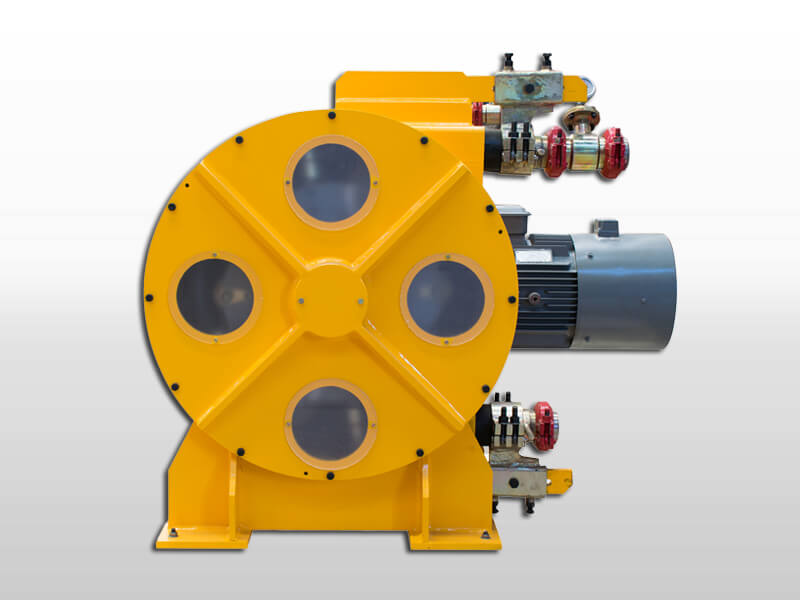

Grout pump station features:

1. Grouting pressure and displacement are step-less adjustable.

2. Simple structure, lightweight, easy maintenance.

3. Double grouting plungers, continuous output flow with less pulse.

4. Less spare parts ensure low maintenance costs.

5. With the function of recording and displaying grouting pump reciprocating times by a counter.

6. The motor has an overload protection function. Hydraulic system with oil temperature overheating protection.

7. Electric motor and hydraulic driven. Anytime, overpressure occurs, the hydraulic safety protection will be worked.

|

LGP400/1000/95/165DPL-E/A Fully automatic mobile grouting plant specification (with electric motor drive): |

||

|

1. Mixer Station 1.1 Pneumatic Pinch Valve: the slurry flows more smoothly; 1.2 Ultrasound Fluid Level Meter: height of agitator can be accurately measured; 1.3 PLC+Touch Screen: manual mode and fully automatic mode. 2. Grout Pump Station 2.1 Grouting pressure, displacement is step-less adjustable; 2.2 Double grouting plungers, continuous output flow with less pulse; 2.3 With the function of record and display grouting pump reciprocating times by a counter; 2.4 The motor has an overload protection function; 2.5 Hydraulic system with oil temperature overheating protection; 2.6 Electric motor and hydraulic driven. Anytime, overpressure occurred, hydraulic safety protection will be worked. 3. Trailer 3.1 With steering function; 3.2 Tripod height is adjustable. |

||

|

Mixer Station |

||

|

Mixer |

Effective Volume |

400 L |

|

Max. Mixing Capacity |

10m³/h |

|

|

Circulation Pump |

Motor Power |

11 Kw |

|

Rotating Speed |

1450r/min |

|

|

Circulation Capacity |

1000L/min |

|

|

Agitator |

Effective Volume |

1000 L |

|

Motor Power |

3.0 Kw |

|

|

Water Supply System |

Motor Power |

4.0 Kw |

|

Displacement |

20 m³/h |

|

|

Head |

30 m |

|

|

Air Supply System |

Motor Power |

2.2 Kw |

|

Displacement |

0.25 m³/h |

|

|

Control System |

Mode |

PLC |

|

Power |

DC 24V |

|

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS

.jpg)