LF40A Lightweight foam concrete production line adopts container structure, it is easy to install, move and transport. LF40A foam concrete production line can be transported by a 4.2m truck. The high and low pressure density stability technology developed by our company is adopted to ensure that the density of light concrete output by the equipment at short distance and long distance is constant, and will not change because of the change of conveying distance or conveying height.

► Application:

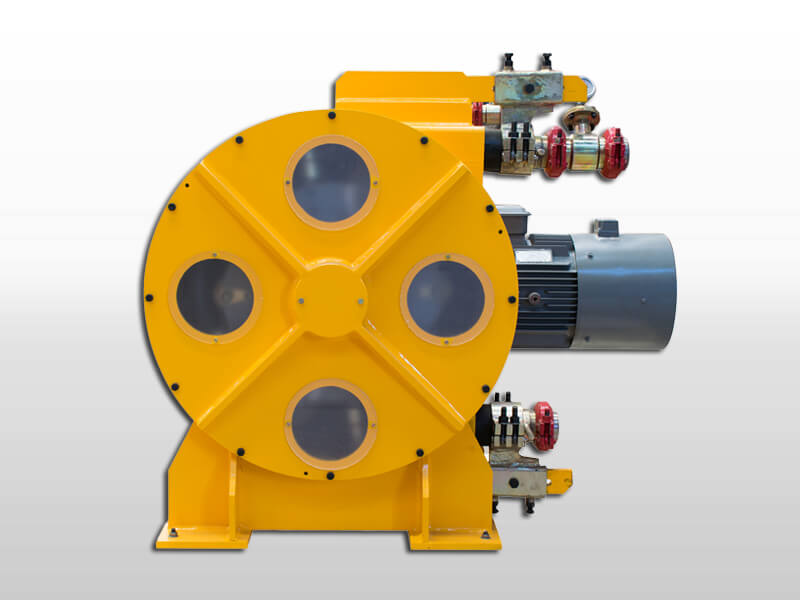

LF40A Lightweight foam concrete production line adopts hydraulic push mechanism, with high pumping pressure, vertical conveying height up to 160 meters, horizontal conveying distance up to 1000 meters, which can meet the requirements of high-rise building roof insulation engineering and ground filling long-distance conveying.

► Features:

1. Powder metering, slurry stirring, and slurry storage are divided into three layers of structures;

2. Standard daily production report output interface or printing device, can be daily cement, fly ash, blowing agent and other materials consumption and light concrete output summary output or printing;

3. The standard ingredients metering device is standard, and cement, powder, water, etc. can be measured separately to accurately control the material ratio;

4. The lightweight concrete density monitoring and control device developed by our company to reach the domestic leading level can be selected to detect the wet density and dry density of the lightweight concrete produced by the equipment, so as to provide reliable data for the engineering quality inspection department;

5. Automatic control, automatic foaming concrete machine equipped with lightweight concrete density monitoring and control device equipment, the equipment can automatically adjust the front material ratio according to the detected density data, so that the production of lightweight concrete density to meet the control set requirements;

6. The lightweight foam concrete production line equipped with lightweight concrete density monitoring and control device adopts touch screen intelligent control system, the working state and various parameters of the equipment can be intuitively displayed on the screen, which is convenient for working state judgment and centralized control.

|

Item |

LF40A automatic lightweight foam concrete production line |

Note |

|||

|

Pump and foam system |

Output(m3/h) |

40 |

Density 450kg/m3 |

||

|

Convey distance(m) |

Horizontal |

1200 |

|

||

|

Vertical |

160 |

|

|||

|

Motor power(kw) |

Pump motor |

30 |

|

||

|

Foaming system |

11 |

|

|||

|

Diameter of concrete cylinder(mm) |

Φ120 |

|

|||

|

Pumping form |

Ball valve double cylinder hydraulic push |

|

|||

|

Density range of lightweight concrete(kg/m3) |

350-800 |

|

|||

|

Foaming ratio |

Adjustable |

|

|||

|

Wet density testing of lightweight concrete |

Accuracy<5% |

Options |

|||

|

Dry density testing of lightweight concrete |

Accuracy<5% |

Options |

|||

|

Cement slurry flow detection display |

Accuracy<2% |

Options |

|||

|

Light concrete flow test shows |

Accuracy<2% |

Options |

|||

|

Foaming agent flow detection shows |

Accuracy<2% |

Options |

|||

|

Conveying pipe diameter(mm) |

Φ50 |

|

|||

|

Mix system |

Volume of mixer(L) |

600 |

|

||

|

Volume of material storage mixer(L) |

720 |

|

|||

|

Motor |

Mixer |

5.5 |

|

||

|

Storage mixer |

4 |

|

|||

|

Water pump |

0.75 |

|

|||

|

Screw conveyor |

5.5 |

|

|||

|

Screw conveyor |

φ165x6m |

|

|||

|

Weighing system |

Cumulative weighing |

|

|||

|

Control system |

Control model |

PLC control, touch screen display and input |

|

||

|

Parameters to print |

Lightweight concrete proportioning printing |

Optional accessories | |||

|

Lightweight concrete productivity printing |

Optional accessories | ||||

|

Size |

The host part (LxWxH mm) |

4100x1750x2065 |

|

||

|

Weight(kg) |

3500 |

|

|||

Configuration of main components:

|

Parameter |

LF40A foam concrete production line |

|

Main oil |

Hefei wanye |

|

Motor |

Shandonghuali/Qingdaohongqi |

|

Valve group |

Taiwan Northman |

|

Press gauge |

Made in Wuxi |

|

Hydraulic rubber pipe |

Italy Manuli |

|

Seal ring |

USA Parker |

|

PLC Units |

Omron |

|

Intermediate relay |

Omron |

|

Proximity switch |

Schneider Electric |

|

Remote control |

|

|

Button |

Schneider Electric |

Configuration list (including Φ50 delivery hose 100m):

| No. |

Name |

Spec. |

Unit |

Quantity |

Note |

|

1 |

Hydraulic hose |

Φ50-20m/pc |

pc |

5 |

|

|

2 |

Hydraulic hose |

Φ50 |

pc |

5 |

|

|

3 |

Water pump |

QX7-18-0.75 |

set |

1 |

|

|

4 |

Water drum |

3m3 |

pc |

1 |

|

|

5 |

Water drum holder |

|

set |

1 |

|

|

6 |

Piston |

BS25C.1-13(Φ120) |

pc |

2 |

|

|

7 |

O Ring |

LF40A |

set |

1 |

|

|

8 |

Proximity switch |

ZLJ-A18-8ANA-Q |

pc |

1 |

|

|

9 |

Water pump accessories |

|

set |

1 |

|

|

10 |

Canvas cover |

Φ165 |

pc |

1 |

|

|

11 |

Rubber sleeve |

170x12x380 |

pc |

1 |

|

|

12 |

Throat hoop clamp |

Φ165 |

pc |

4 |

|

|

13 |

Foam agent |

HF30 |

drum |

1 |

(200Kg/drum) |

|

14 |

Remote control |

Wireless 220V |

pc |

1 |

|

|

15 |

Tool box |

|

set |

1 |

|

|

16 |

Operate guide |

LF40A |

pc |

1 |

|

|

17 |

Certification |

LF40A |

pc |

1 |

|

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS