LF10 foam concrete (CLC) mixing and pump machine is a middle-size foam concrete plant which is simple in operations, low cost, mobile, integrated system for mixing, foam-generating and pumping. It has the features of continuous feeding of material, water supply system, low power requirement and higher pumping height.

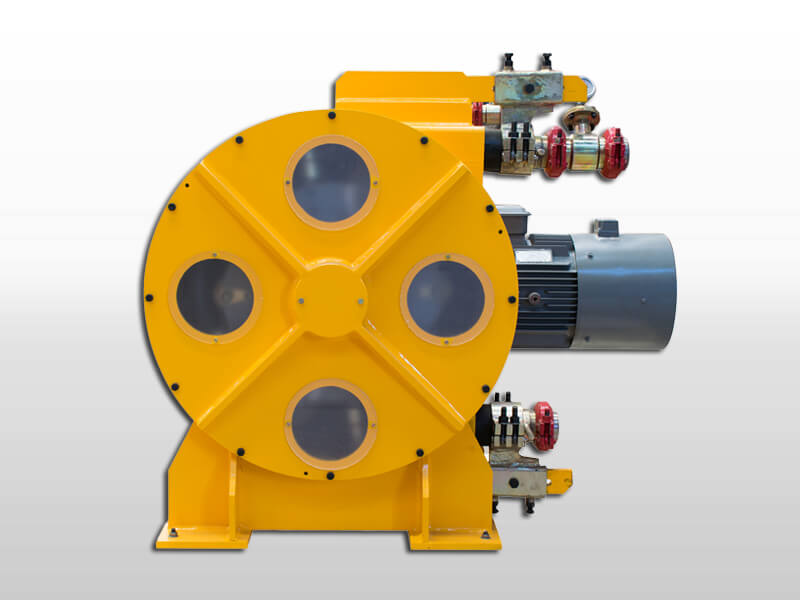

LF10 foam concrete machine for roof insulation adopts peristaltic pump to realize a better performance. Peristaltic pump is most suitable pump for delivering foam concrete, and it can keep the quantity and ratio of foam very well and reduce the damage to the bubble. The density range it can produce is 250 -1600kg/m3.

What is more, peristaltic pump almost need no maintenance and the service lift is much longer than other kinds of pump. So, LF10 foam concrete mixing machine can save your usage cost greatly.

► Application:

1. LF10 foam concrete machine for roof insulation can be used for providing insulating layer on the floor. It can adjust the density according the mix design from 250-1600kg/m3.

2. LF10 foam concrete machine can used for roof insulation of refrigerated storage space. Besides, it can be used for filling tunnel and mined.

3. LF10 foam cement machine can be used for producing foam concrete panel and CLC block.

1. Mixing system, foaming system and pump are designed as a whole body, small size and easy to move.

2. Our LF10 CLC machine can automatically adjust the density.

3. Our foam concrete block machine can easy to control and operate.

4. Almost need no wearing parts. The maintenance cost and using cost is much lower.

| Model | LF10 |

| Max .theoretical concrete put(m³/h) | 10 |

| Motor power(kw) | 7.7 |

| Theoretical vertical conveying height(m) | 40 |

| Theoretical level transmission distance(m) | 300 |

| Mixer tank capacity(L) | 350 |

| Filling height(mm) | 1000 |

| Feeder size(mm) | 2990*760*830 |

| Overall dimension(mm) | 2390*1490*1440 |

| Total weight(kg) | 1000 |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS