► Description:

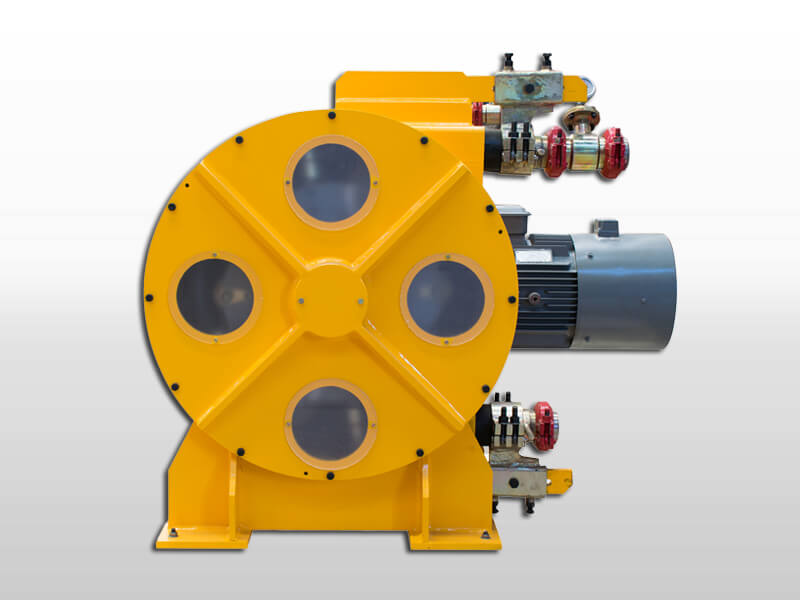

LPXT200-D/A Dry Screed Mortar Mixer Pump with Air Pressure-Screed Machine delivers consistent, dependable power for uninterrupted handling of construction materials. Equipped with a 4-cylinder engine featuring an advanced digital dashboard, operators can effortlessly monitor critical parameters while benefiting from a modular design that simplifies maintenance procedures. This innovative solution translates to tangible efficiency gains in screed applications, offering both operational ease and practical performance advantages.

The upgraded mortar mixing and conveying machine excels in multi-directional material transfer, combining horizontal and vertical conveying capabilities with a high-performance built-in air compressor. This compressor generates robust pressure and airflow, ensuring seamless material flow across the entire working envelope. By leveraging this optimized machinery, contractors can achieve superior leveling results with reduced labor hours and accelerated project timelines compared to conventional methods.

► Operating Principle:

① Add Material 1 to Mixing Tank 5.

② Put on the sealing cover 2 and press it down firmly.

③ The materials are fully stirred in the mixing tank 5.

④The air compressor starts to generate compressed air 3 with sufficient pressure, which enters the mixing drum 5 and the lower pipeline.

⑤The air compressor starts to generate compressed air 3 with sufficient pressure, which enters the mixing drum 5 and the lower pipeline, completing material conveying.

► Application:

LPXT200-D/A Dry Screed Mortar Mixer Pump with Air Pressure-Screed Machine is designed for mixing and transporting screed. It is ideal for all dry, semi-dry or wet screed applications, with products such as mortar, sand or light products such as clay.

► Features:

|

Model |

LPXT200-D/A Dry Screed Mortar Mixer Pump |

|

Diesel Engine |

60KW |

|

Vessel Capacity |

Gross 260L / Net 200L |

|

Output Capacity |

5m³/h |

|

Transfer Range |

Horizontal 220m, Vertical 50 Floor |

|

Operating Pressure |

2-4bar |

|

Max. Vessel Pressure |

8bar |

|

Compressor Flow Rate |

6m³/min |

|

Aggregate Size |

16mm |

|

Chassis Tow Connection |

Ball Coupling |

|

Fuel Tank |

50L |

|

Dimension L×W×H |

5320×1700×2000mm |

|

Weight |

2415kg |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS

.jpg)