► Description:

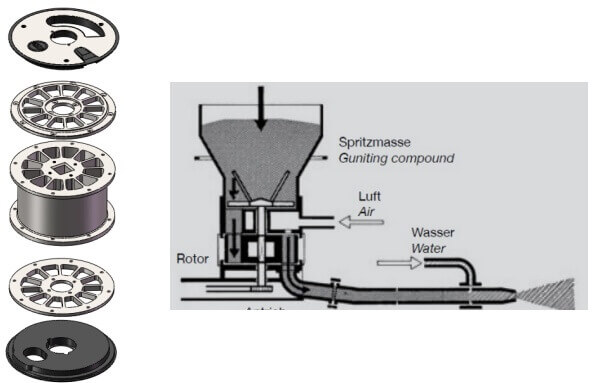

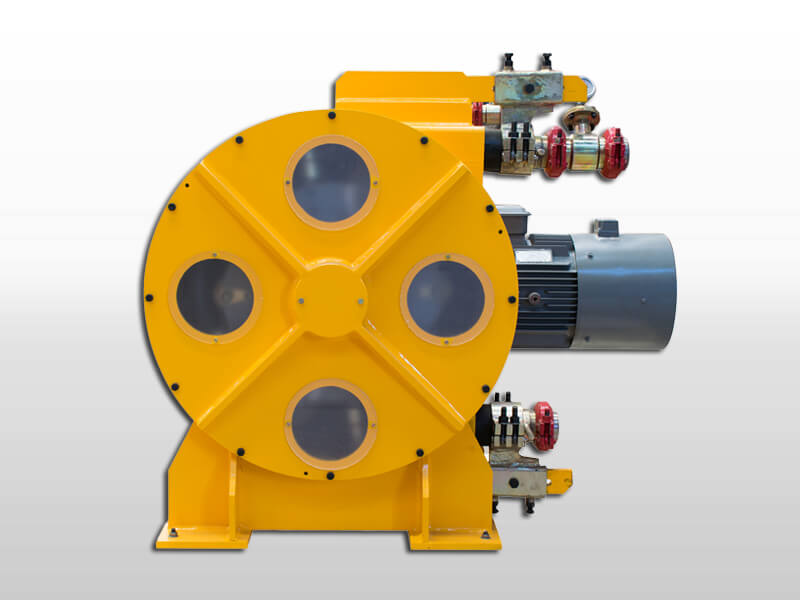

LZ-3ER/SC Dry Mix Refractory Gunning Machine is purpose-built for refractory dry-mix shotcrete works, employing the rotor principle in its design. Its long-standing and reliable construction ensures exceptional sturdiness, straightforward installation, user-friendly operation, cost efficiency, and safety, setting it apart as an outstanding gunning machine. Its adaptability to multiple configurations makes it the go-to equipment for projects of small to medium sizes.

► Application:

Application Areas of LZ-3ER/SC Dry Mix Refractory Gunning Machine:

1. Steel and Metallurgical Industry

Blast Furnace Repair: Used for spraying refractory materials to repair blast furnace linings and extend service life.

Converters and Electric Furnaces: Spraying refractory coatings to improve furnace corrosion resistance.

Torpedo Cars and Tundishes: Spraying refractory materials to protect containers from high-temperature slag corrosion.

2. Cement Industry

Rotary Kilns: Spraying refractory materials to repair kiln linings and reduce heat loss.

Preheaters and Calciners: Spraying refractory coatings to improve equipment's high-temperature resistance.

3. Power Industry

Boiler Linings: Spraying refractory materials to protect boiler walls from high-temperature corrosion.

Incinerators: Spraying refractory coatings to improve incinerator corrosion resistance.

4. Non-Ferrous Metals Industry

Smelting Furnaces and Reverberatory Furnaces: Spraying refractory materials to repair furnace linings and improve production efficiency.

5. Other Industries

Waste Incinerators: Spraying refractory coatings to extend incinerator service life.

Chemical Industry Reactors: Spraying refractory materials to protect reactors from chemical corrosion.

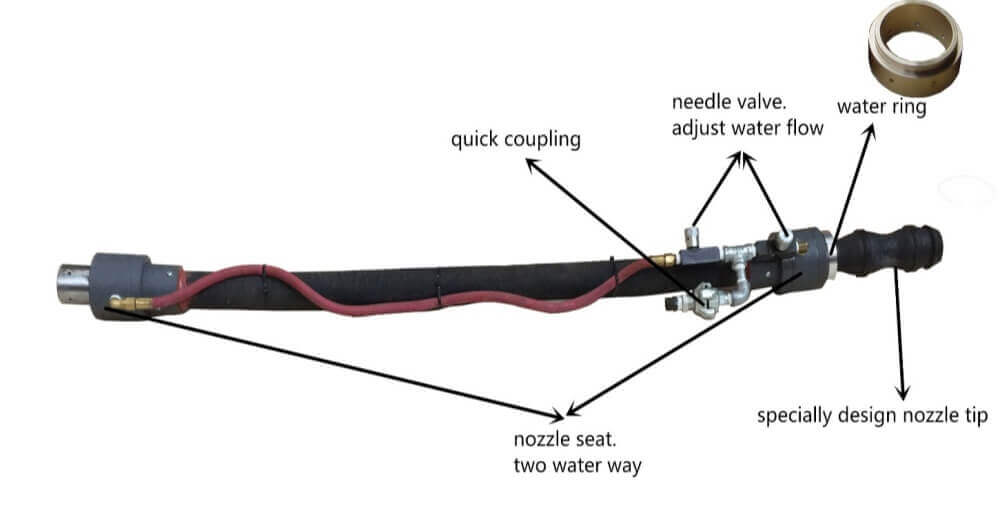

By utilizing the LZ-3ER/SC dry mix refractory gunning machine, you can achieve a spraying flow at the nozzle that is characterized by minimal dust generation and superior performance. LZ-3ER/SC Dry mix refractory gunning machine spraying effect:

► Features:

|

Model |

LZ-3ER/SC Dry mix refractory gunning machine |

|

Rated Output |

0~3m3/h (0~6tons) |

|

Max. Horizontal Conveying Distance |

200m |

|

Max. Aggregate Size |

Φ10 mm |

|

Conveying Hose Inner Diameter |

38mm |

|

Operating Air Pressure |

0.2-0.4MPa |

|

Air Consumption |

5~6m3/min |

|

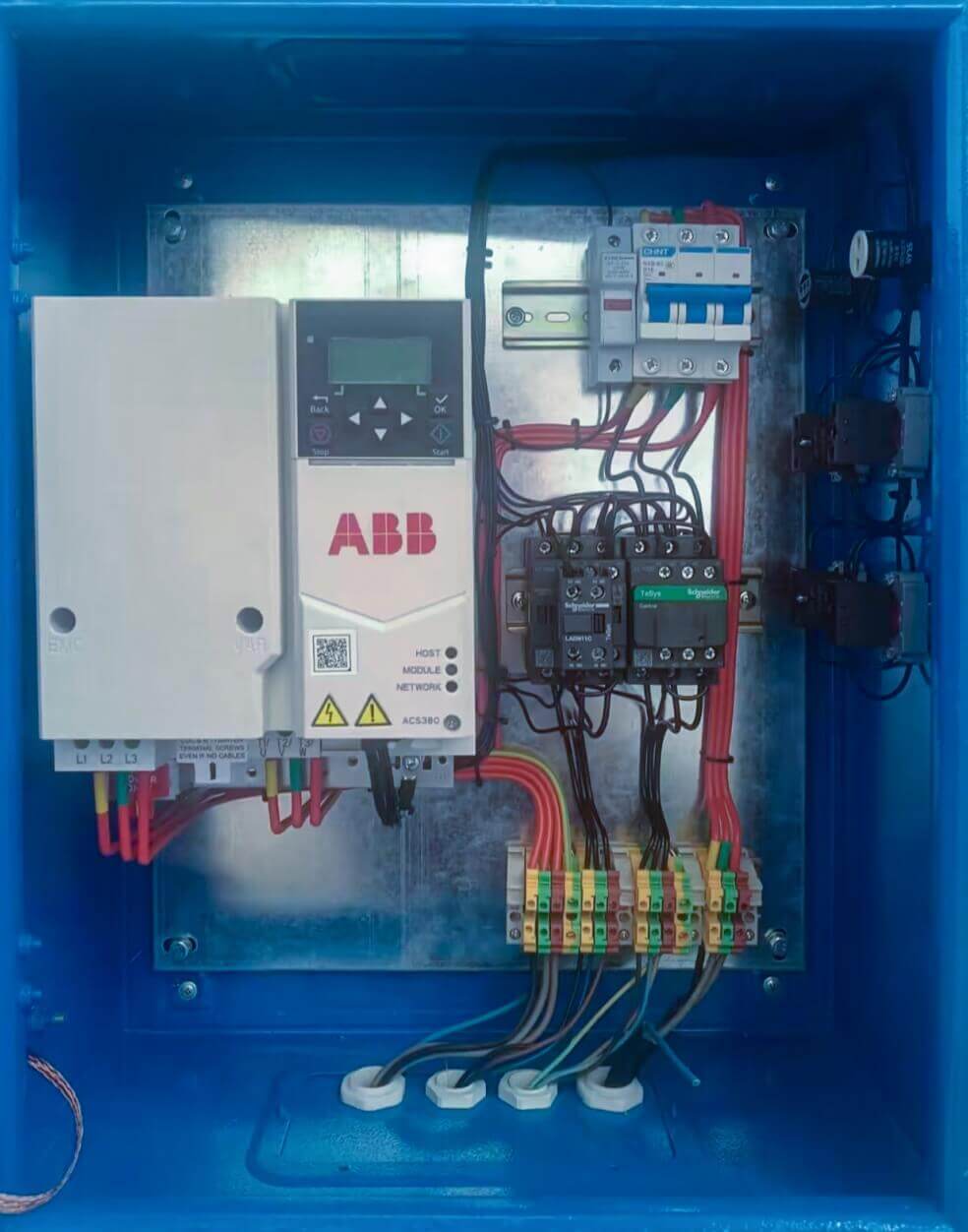

Motor Power |

4kw |

|

Voltage |

3 phase, 380V, 50Hz |

|

Material Charging Height |

1.2m |

|

Rotor Speed |

0-13.2r/min |

|

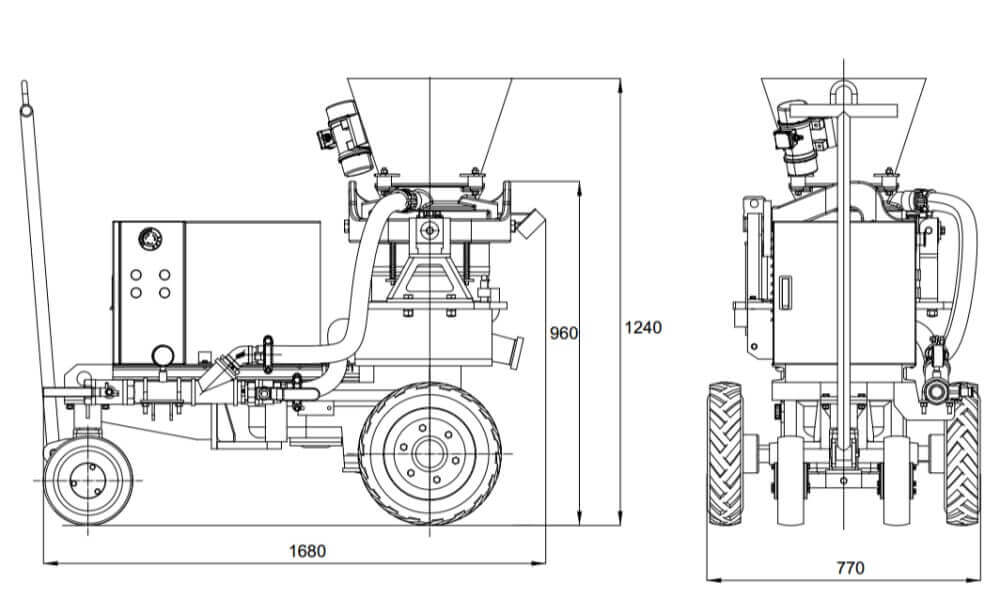

Overall Dimension |

1680×770×1240mm |

|

Weight |

530kg |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS