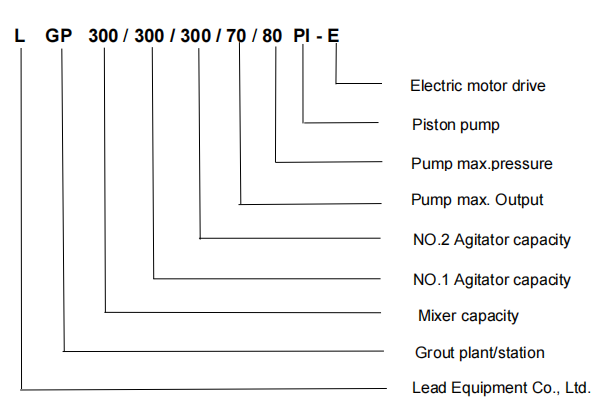

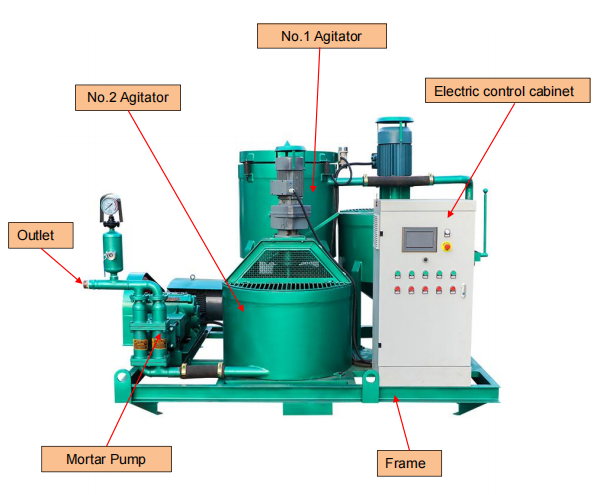

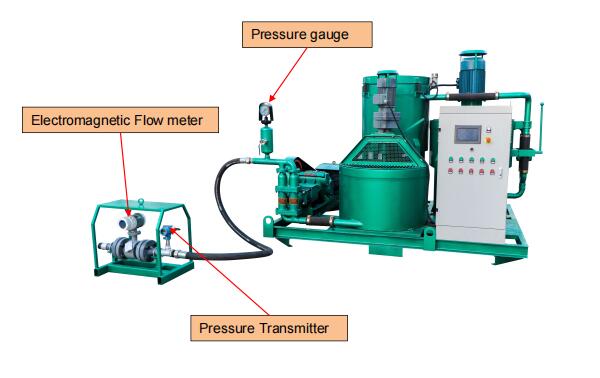

LGP300/300/300/70/80PI-E mortar grout station is a combination of one grout mixer, two agitators, and one mortar grout pump in one machine, it is very easy to operate and move.

LGP300/300/300/70/80PI-E mortar grout station is suitable for making cement mixture and mortar cement mixture, the high shear grout mixer volume is 300L, the No. 1 agitator volume is 300L, No. 2 agitator volume is 300L, grout pump adopts frequency control, so the Max grout flow is 70L/min, the Max pressure is 8Mpa.

This mortar grout mixing station is driven by an electric motor and a mechanical plunger-type injection pump. Compact in size, easy to operate, and also takes a small place.

Working principle of LGP300/300/300/70/80PI-E cement slurry grout mixing station:

Evenly mixed slurry convey to No. 1 agitator. Add sand to No. 1 agitator and mix. Evenly mixed mortar cement mixture flows into No. 2 agitator through discharge outlet. Grouting pump sucks mixture from No. 2 agitator and finish the grouting, gunite and backfilling etc. project. Grouting, while the next round of mixing can be carried out, thus the grout station achieves continuous work.

► Application:

The cement slurry grout station is mainly used in municipal, highway, railway, hydropower, construction, mining, and another construction site for mortar grout.

► Features:

1. Grouting pressure, the output is step-less adjustable.

2. Continuous output with a small pulse.

3. HMI interface, flow, and pressure can be visualized.

4. With CE, and ISO certification.

5. Cement slurry grout pump station has a simple structure, is lightweight, and has easy maintenance.

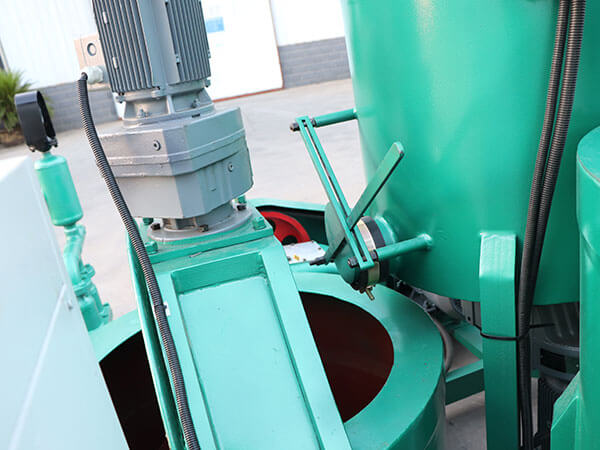

6. Mixer and agitator switch by using a squeeze handle, it is safe, reliable, and easy to operate.

7. High-speed vortex mixer ensures mixing quickly and evenly.

8. Flameproof electric cabinet, protection grade IP56.

| Name | Data | |

| Type | LGP300/300/300/70/80PI-E mortar grout station | |

| Mixer | Capacity | 300L |

| W/C ratio | 0.5~1 | |

| Rate Rev. | 1450 rpm | |

| Power | 7.5Kw | |

| NO.1 Agitator | Capacity | 300L |

| Rate Rev. | 49 rpm | |

| Power | 2.2Kw | |

| NO.2 Agitator | Capacity | 300L |

| Rate Rev. | 36 rpm | |

| Power | 1.5Kw | |

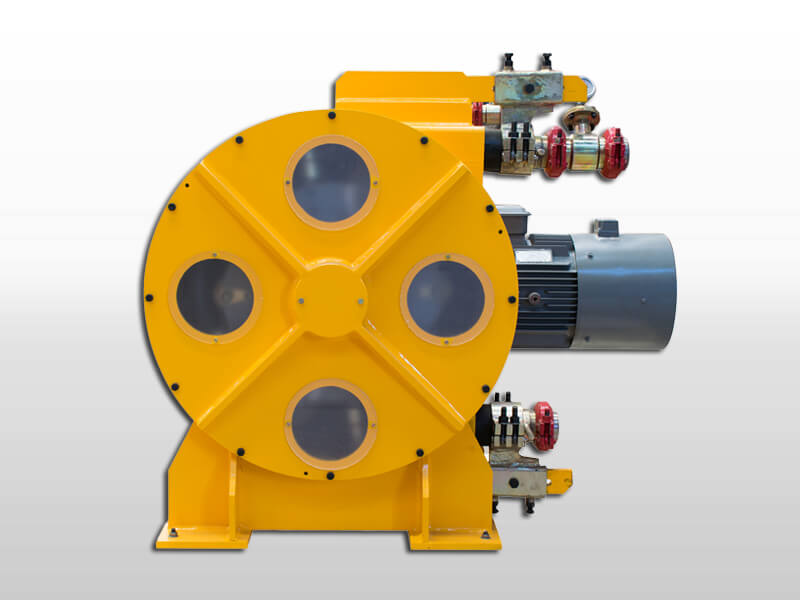

| Pump | Type | Mortar Pump |

| Output | Max 70L/min | |

| Pressure | Max 8Mpa | |

| Power | 11Kw | |

| Power requirements | Voltage 3 Phase 380V,50Hz | |

| Dimension | 2800×1900×1650mm | |

| Weight | 1350Kg | |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS