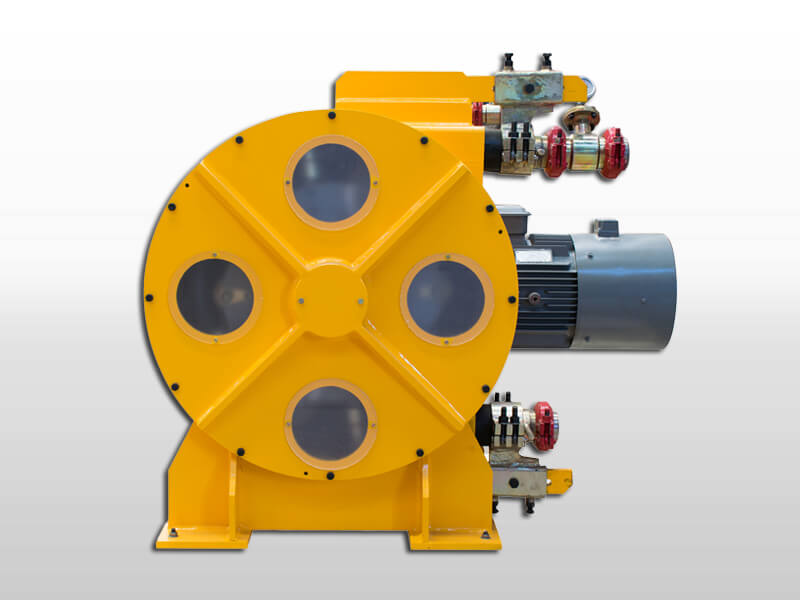

LF30 high capacity foam concrete machine is a large-sized cement foaming machine, pumping, foaming and mixing system assembles as a whole, convenient to use. It has the continuous feeding system and water supply system, with high pumping height and low power requirement. And it adopts digital control technology, this cement foam machine can exactly adjust foam cement density. More importantly, it adopts hydraulic piston system to convey the foam concrete, which can greatly improve the service life, and it also has high pumping pressure that can satisfy the requirements of high-level pumping works. Besides that, foam concrete pumps are equipped with wheels that can realize portable site transition at any time.

► Application:

-Cellar, basement and arch filling.

-Sewers and Drains filling.

-Horizontal floor heightening.

-Water tank and fuel tank building.

-Platform filling and mending.

-Garden and rockeries.

-Foam concrete block.

-Foamed concrete precast ,hollow wallboard casting.

-External wall thermal insulation.

-Thermal insulation roofing.

-Thermal flooring.

-Upstanding beam foundation ditches filling.

-Sound insulation and fire protection walls.

-Playground and track construction.

-Sound insulation layer, tunnel lining filling.

► Features:

1. Adopting wear resistant metal, sturdy and durable.

2. LF30 concrete block making machine is with full automatic control system, to adjust the foam concrete density easily.

3. Adopting hydraulic piston system to convey the foam concrete to the construction plant on-site, stable flow, small fluctuation.

4. LF30 block making machinery is with static mixer can reduce the ratio of foam loss and guarantee the quality of the foam concrete product.

5. LF30 block making machinery interlocking is equipped with travelling wheel, easy moving and position.

| Model | LF30 | |

| The theoretical output (m³/h) | 25-30 | |

| Max.convening distance(m) | Horizontal | 500 |

| Vetical | 80 | |

| Power | 440V, AC, 3 phase, 50HZ | |

| Total motor power(kw) | 21 | |

| Mixing tank capacity (L) | 580 | |

| Filling height (mm) | 1100 | |

| Over dimension(mm) | 2200*1540*1760 | |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS