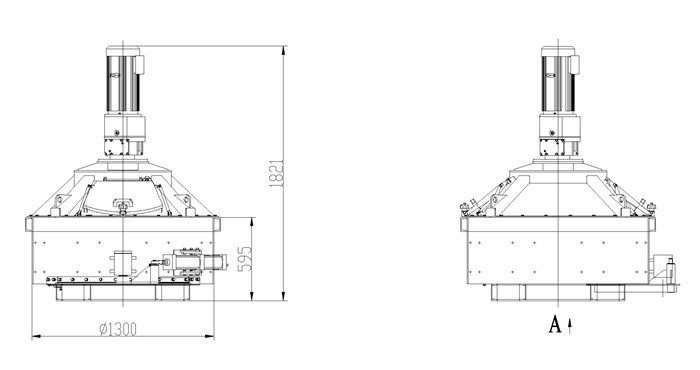

Planetary concrete mixer for refractory production

2021-12-27 17:20:52

Planetary concrete mixer for refractory production:

Leadcrete has supplied more than 50 mixers to manufacturers of high-quality concrete products, refractory materials, and drywall construction materials since the new turbine mixer series LMC was presented in April 2015. The huge majority of these new planetary concrete mixers had been delivered to renowned customers in German-speaking regions. Further turbine mixers were supplied to well-known customers in foreign countries in and outside Europe.

In the meantime, the Leadcrete planetary concrete mixer for refractory production is operating in the field of face mix, colored, fiber-reinforced, and polymer concrete as well as self-compacting and ultra-high-performance concrete, with excellent mixing results. The new LMC series has also been successfully proven for refractory materials and drywall construction materials.

Suitable for various mixing tasks and batch sizes:

The idea behind the development of the pan mixer for refractory production, for which a patent has been applied, was to mix special concrete grades in an intensive and efficient way by means of as few mixing tools as possible. One of the main objectives was that the turbine mixer should ideally be quality for the most difficult mixing tasks and most different batch sizes. Thus, even minimal quantities of less than 10 % of the maximum filling capacity of the mixer were perfectly mixed in practice. The company also intended to reduce contamination and cleaning efforts inside the mixer.

This resulted in the planetary pan mixer for refractory production, which not only meets this criterion but even further improves the quality of products to be mixed, in particular, when it comes to more difficult mixing tasks. Process times in terms of mixing and discharging were shortened, and one and the same mixer size allows for an enormous variability of batch sizes. For this series, the supplier could make use of the well-proven components of the planetary mixer series. Every single mixer can be perfectly assembled according to the respective product to be mixed.

In order to make optimum use of possible configurations, a new type of code was implemented for the new Leadcrete series. The mixers are configured in accordance with the specific requirements of the individual customer combining the components needed correspondingly, and not as usual, according to the maximum filling capacity of the mixer. The type designation includes the size of the planetary concrete mixer for refractory production and the number of drives used for the mixing turbine, besides the drive power.

Outstanding test results Leadcrete had the mixing action scientifically tested from planetary pan mixer for refractory production, especially concerning the production of concrete grades of the new generation. In this regard, the production of steel fiber-reinforced concrete (SFRC), self-compacting high-strength concrete (SCC), self-compacting lightweight concrete (SCLC), and ultra-high-performance concrete (UHPC) were assessed. These concretes are considered to be some of the most demanding concrete grades of the new generation. The homogeneity of the mix was classified on the basis of standard DIN 459-2 (Building Materials Machines - Mixing Machines for Concrete and Mortar - Part 2: Methods of testing the mixing effect of concrete mixers) as well as according to the RILEM Final Report TC 150-ECM (Efficiency of Concrete Mixers – Assessment and classification of performance mixers). All four concrete grades (SFRC, SCC, SCLC, and UHPC) tested obtained outstanding test results, as stated by the mixer supplier. Apart from the planetary concrete mixer for refractory production quality, among others, the power input of the mixer was evaluated in order to assess the effective power. In this process, the IBU ascertained that the energy input into the concrete is about 80 % higher in the production of UHPC than in the production of SCC, using a nominal filling capacity of 500 liters. Thus, the high-performance planetary concrete mixer for refractory production is in the position to provide the high energy demand of UHPC, which is due to the many shear planes required particularly for this concrete. Leadcrete series already several times installed in the pan mixer for refractory production and precast concrete industry, Leadcrete is one of the leading suppliers of high-performance mixers, providing as well the conversion and modernization of plants. In the last few years, a large number of concrete plants, in China alone, were modernized in order to meet the recent requirements of the customers. For this purpose, the new

LMC series planetary concrete mixer for refractory production with a mixing turbine was successfully installed by several customers. As a one-source supplier, Leadcrete offers the entire range from the preliminary planning together with the customer up to project planning, installation, and commissioning, including customer service and an extensive range of spare parts.

If you need more details, please contact us by email. Email address: sales@leadcrete.com

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS