Emergency grouting equipment selection in urban subway and underground engineering

2019-08-21 15:40:43

With the rapid development of China's railway construction industry, construction and railway operations are becoming more and more important. The construction of large-scale urban rail transit in China's provincial capital cities and coastal second-tier cities is in full swing, and the subsequent collapse, water inrush and quicksands have caused great problems to the construction units, which requires the construction units to be cautious and properly handled. Through years of production and on-site experience, our company has summed up a complete set of experience to adapt to on-site emergency grouting equipment, and can configure corresponding equipment and facilities according to different site conditions.

The response measures for collapse, water inrush and quicksand:

In the event of collapse, the front stage needs to be filled, grouted and consolidated, and then dug. When the collapse layer is relatively shallow, the slope protection pile is laid at the corresponding position, and then excavated, which can be grouted and consolidated after the slope protection pile.

When the water is very large, you need to pump the water with the submersible pump first, and then grout the water outlet.

When the quicksand occurs, it is directly grouted and consolidated.

When grouting, the main solution is double-liquid slurry. According to the water outlet or the geological conditions of the quicksand, the appropriate initial setting time is selected for the double slurry concentration.

As a rescue preset device, large cranes and excavators can use social power. For drilling, grouting equipment, appliances and corresponding grouting materials, careful study is needed to make reasonable selection. After selecting the equipment, we must first train the rescue personnel, including understanding the basic grouting process, equipment specific operation and maintenance, corresponding appliance management knowledge, formulating personnel and equipment management system, ensuring the reliability of equipment storage location, and establishing rescue personnel. Communication network and duty system.

Drill selection:

Advantages: The price is cheap. Some rigs can be rotated 360 degrees. Horizontal holes and inclined holes can be used in the tunnel. Construction on the ground, with the derrick lifting the drill pipe faster.

Disadvantages: For concrete and asphalt pavements, the pebble layer and backfill soil are difficult to drill, especially in urban construction. As a subway rescue engineering equipment, it is necessary to equip the drilling rig with impact capability, first drill the pilot hole, and then drill through the hard road surface by the geological drilling machine.

Advantages: moderate price and high cost performance. The power head has a long stroke, generally about 2 meters, and the rotating torque is large, 1000-5000N.M, the drilling efficiency is high, and the horizontal and inclined holes can be used, and the lifting force is relatively large, and can reach 40Kn or more. The rig with the track walking mechanism is very convenient to move.

Disadvantages: Despite the large rotational torque, it is still difficult to drill for the concrete and asphalt pavement, the pebble layer and the backfill.

3. High-end configuration

Crawler drill with impact power head

Advantages: On the basis of the engineering power head drilling rig, the power head and the impactor can easily pass through the concrete and asphalt pavement, and also have a good drilling effect on the pebbles and the backfill layer. It is easy to move and has high drilling efficiency.

Disadvantages: The price is high, generally more than ten times that of the corresponding geological rig. The volume is relatively large and does not adapt to the construction inside the tunnel. When selecting such a rig, it is not recommended to use a pneumatic drill. Because the wind-driven drilling rig is mainly used for drilling holes in rocks, the torque and lifting force are relatively small. Some city subway rescue teams have such rigs, which can only be used for pilot holes, and the equipment utilization rate is extremely low.

The drilling tool selection:

The above drilling rig uses drill pipe. It is recommended to use STM-R780 geological drill pipe, diameter 50-80, and chrome-molybdenum alloy steel for joint material. The heat treatment process should be reasonably selected and strictly controlled. The inner tube material of the double-layer drilling tool must be made of standard 1Cr18Ni9Ti, and the joint welding place should be tested by high pressure.

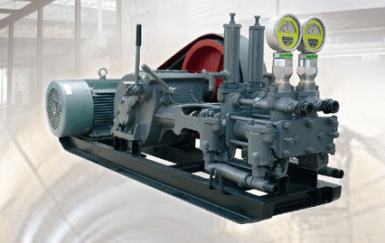

The grouting amount is within 10 cubic inches, and a mechanical variable-variable two-liquid grouting pump is selected. It can be single or double liquid grouted.

The two-liquid grouting pump must have a two-cylinder independent type single-cylinder double-acting type, which is easy to form a two-liquid mixing in the cylinder, and the result is that the pump is blocked.

The grouting amount is more than 10 cubic inches. It is recommended to use a two-liquid constant-power hydraulic grouting pump. The grouting efficiency is high, and the equipment can be operated under full load, and the flow rate is automatically adjusted according to the pressure.

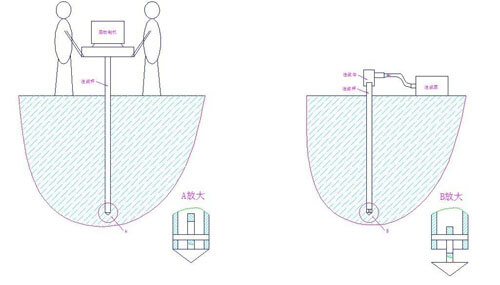

Compact grouting:

Filled formations often require compact grouting to increase load carrying capacity, and some underground passages also require compact grouting to enhance water resistance.

The grouting pipe can be connected with a common seamless pipe of ∮28-50, and the grouting pipe can be laid by vibration method. The amount of grouting is within 50 liters.

There is a movable head in the grouting head. When the grouting pipe enters the soil layer, the moving head is retracted to ensure that the soil does not enter the pipe, and the movable head is ejected by the slurry when grouting. The hydraulic pipe extractor can be used for the grouting pipe.

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS