Phone/Wechat

Phone/Wechat

+86-18538591025

ADDRESS

ADDRESS

Xisihuan Ring-Road East, Tielu, Xiliu Lake sub-district, Zhongyuan District, Zhengzhou, Henan China

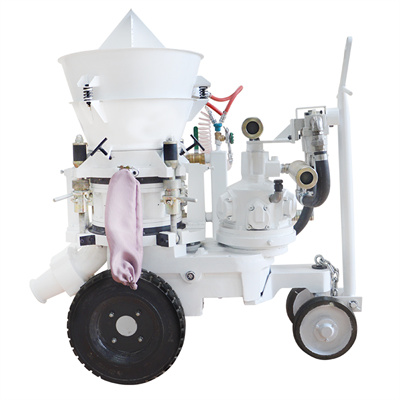

Fire-resistant material spray machine

Lead Equipment Co., Ltd. is a manufacturer of fire-resistant material spray machine. We have developed LZ series fire-resistant material spray machine for sale, output from 1m3/h to 9m3/h, electric motor and air motor are available options for customization.

Our fire-resistant material spray machine is specifically designed for refractory spraying and shotcrete castable refractory application, as well as for concrete shotcrete application. It is widely used for repairing of electric arc furnace in hot and cold conditions. And it also can be applied for concrete layer in a boiler chimney, cement industry, steel furnace industry etc.

Take LZ-5AR fire-resistant material spray machine for example:

LZ-5AR fire-resistant material spray machine is driven by air motor, its operating air pressure is 2-4bar, its rated output is 1-5m3/h. And its max horizontal conveying distance is 100m.

Features of LZ-5AR fire-resistant material spray machine:

1. 5 cylinders piston air motor, more powerful;

2. Pneumatic transmission system, the pneumatic triple pieces is refers to the air filter, relief valve and oil mist;

3. Clean dust gun;

4. Collect dust bag;

5. Heavy duty solid wheel;

6. Coupling and clamp, the coupling and clamp are optional;

7. Light weight nozzle, new pre-damping nozzle:

a. Low rebound, low dust.

b. Reduce additive water amount.

c. Improve refractory compactness and strength.

8. Blaster rubber hose;

9. Low maintenance cost;

10. High pressure water pump, 6 bar pressure make sure to add water fully atomize, mix evenly.

In addition, we have other types fire-resistant material spray machine for sale.

LZ-5ER fire-resistant material spray machine is driven by electric engine, its operating air pressure is 2-4bar, its rated output is 1-5m3/h. And its max horizontal conveying distance is 100m.

LZ-3AR fire-resistant material spray machine is designed for refractory dry-mix shotcrete with air motor drive. Its operating air pressure is 2-4bar, and the rated output is 1-3m3/h.

LZ-3ER fire-resistant material spray machine operating air pressure is 2-4bar, and the rated output is 1-3m3/h. Its power unite are respectively 3phase, 380V, 50Hz. Its electric engine power is 4Kw.

LZ-3ER/S fire-resistant material spray machine is an upgraded version of our company’s hot-selling LZ-3ER fire-resistant material spray machine. The newly designed LZ-3ER/S fire-resistant material spray machine effectively reduces dust and greatly improves the spraying effect. Its rotor body hole and rigid liner are changed from round hole to fan-shaped hole, which increases the blanking volume and reduces the friction area; under the same output, it can effectively reduce the speed and reduce the power.

LZ-3ER/S fire-resistant material spray machine operating air pressure is 2-4bar, and the rated output is 1.5-3m3/h. Its power unite are respectively 3phase, 380V, 50Hz. Its electric engine power is 4Kw.

The following preparations should be made before we use the fire-resistant material spray machine:

1. Check whether there is air leakage and water running in the pipe of the shotcrete and deal with it in time.

2. Inspect the abrasion of the feeding pipeline, and repair or replace it in time when problems are found.

3. The feeding pipeline should be smooth and no dead bend or hard bend is allowed to prevent the pipeline from blocking or causing serious wear.

4. Check and clean up the sundries in the bin.Then spray onto the specific construction area.

Contact us for details of fire-resistant material spray machine:

If you want us to help you recommend a suitable fire-resistant material spray machine, please let me know the following question:

1. What's the project you will use the machine do?

2. What is the output do you need, 3m3/h, 5m3/h, 7m3/h, 9m3/h?

3. Drive type mode? Do you want electric engine or air motor?

4. Do you have any other special requirements for this machine?

You can send your demands to our email, email address: sales@leadcrete.com.

Pre:Good quality cement grout mixer machine for sale

Next:Large capacity hydro mulch soil spraying planter equipment