Shotcrete pump for spray refractory materials

2020-03-25 17:53:11

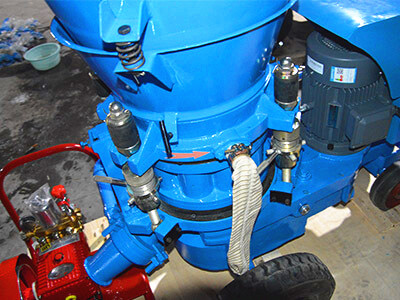

Shotcrete pump for spray refractory materials

Leadcrete Shotcrete pump for spray refractory materials is a dry monolithic refractory material designed for dry spray gun equipment. The spray gun is applied by a special machine that uses compressed air to push the dry (or pre-wetted) spray gun through the hose into the target. Add water (or additives) to the nozzle to wet the dry mixture and make it stick to the surface.

Leadcrete refractory gunite machine price is reasonable, stable in performance, uniform and continuous spraying, and easy to move. It is the preferred equipment for refractory spraying.

Leadcrete spray refractory materials machine is well received by customers at home and abroad for its favorable price, high quality and stable performance.

1. Variable Output with ABB variable frequency drive.

2. Bag cutter and flat hopper with vibrator.

3. Collect dust bag.

4. Clean dust gun.

5. Heavy-duty solid wheels.

6. Coulping and clamp.

7. New type pre-dampening nozzle assy.

8. Blast rubber hose.

On-site safety: Leadcrete shotcrete machine for spray refractory is placed stably, the pipes are firmly connected, the power supply is connected correctly and safely (the voltage is correct, the direction is correct), and the rotating part must not touch the rotating part to avoid accidents.

Start-up and shutdown steps: Before starting the refractory spray repair machine, check the rubber plate for abrasion and the blanking system for blockage, and then symmetrically press the four compaction mechanisms (for example, when the compaction mechanism is initially stressed, follow 1 to 3 and 2) For pair 4, press one or two turns in a cycle of half a turn in order to ensure that no leakage occurs, and the abraded rubber sheet will be pressed slightly more.)

After confirming that the lines and pipes are connected and ready, you can first turn on and open the compressed air on the air path to check whether there is air leakage and tighten it. Then stop the air and turn on the liquid pump to check the effect of liquid addition and atomization. Adjust the air valve and the filling valve to the appropriate position (this time the material shows that only the upper air path is opened, and the discharge is more uniform. Leadcrete refractory materials spraying machine is recommended that the lower air path be opened a little to avoid the swirling air holes being blocked. Different materials can be adapted according to the change of the upper and lower air paths. To the right effect).

Then start feeding and start spraying. If the material is loose, you can not open the vibrator. In order to have a uniform reference, the amount of material in the hopper should be less than half of the hopper during normal spraying, and empty hoppers should not be allowed during spraying. This is a matter to be noticed by the workers next to the refractory gunite machine, and the corresponding spraying surface construction staff must have automatic adjustment awareness. For example, when the material is not yet available, the liquid valve can be appropriately reduced and sprayed in different places to avoid being too wet to affect the back spraying. When the material is discharged, restore the liquid valve to the original proper position (based on the rotation range) Master), and then adjust the filling valve to the appropriate position according to the wet and dry conditions of the discharge, suitable for small range spraying, so as to adjust the wet, dry and smoothness.

After spraying or to stop spraying, the material in the hopper needs to be discharged first, and then it can be shut down. After the material in the pipeline is discharged, the liquid pump is turned off, and then the compressed air is turned off. After shutdown, it is recommended that the refractory gunite machine repair machine be compacted and loosened half a turn (re-tighten it next time) to prevent the rubber plate from being deformed by heat and causing it to be difficult to start next time.

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS