► Description:

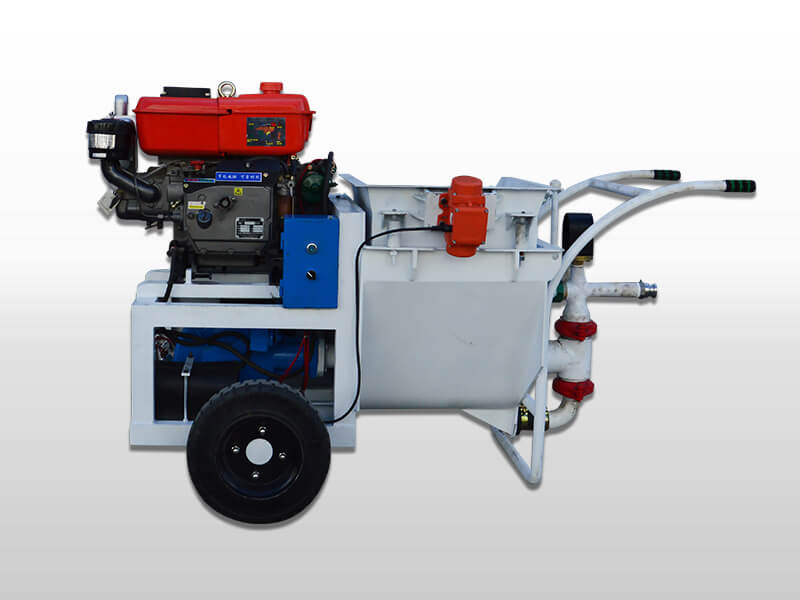

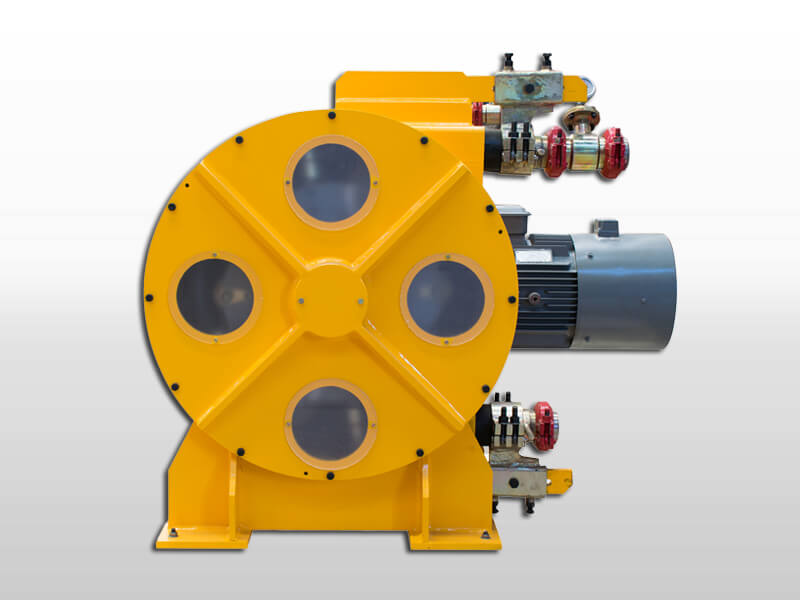

LMP35/30 piston mortar pump is a piston pump with one single cylinder & single acting, mainly was designed for conveying and spraying mortar or plaster. This pump has compact structure, reliable operation, low failure rate, convenient cleaning, easy maintenance and high pumping pressure etc. advantages, so it has widely been using for mortar spraying, pumping and grouting in tunnel excavation and maintenance, mine engineering, constructing dams, bridges and foundation treatment etc. projects. The pump also has been using for mortar and putty pumping and spraying civil buildings.

► Application:

This pump has compact structure, reliable operation, low failure rate, convenient cleaning, easy maintenance and high pumping pressure etc. advantages, so it has widely been using for mortar spraying, pumping and grouting in tunnel excavation and maintenance, mine engineering, constructing dams, bridges and foundation treatment etc. projects. The pump also has been using for mortar and putty pumping and spraying civil buildings.

► Features:

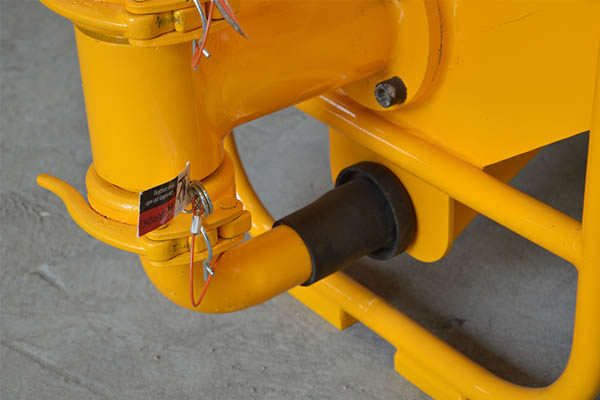

1. Single cylinder & single-acting, ball valve, quick clamp connection, operation and cleaning conveniently;

2. Adopt special design rubber parts to connect to the feeding and back port, easy to disassemble;

3. V belt and gear transmission, high efficiency, low failure rate;

4. The special design of the working valve chamber ensures the mortar flow easily, small resistance,

no deposition;

5. The screen adopts rubber spring with cone bolt installation, convenient disassembly;

6. The mixing shaft in the hopper is directly linked to the piston rod, thus this shaft is synchronously moved with the said piston rod effectively prevent mortar precipitation;

7. Equipped with special mortar nozzle, making spraying operation more smoothly, continuously and reducing the rebound effectively.

| Item | Technical data |

| Working Pressure | 0~30bar |

| Output | 35L/min |

| Reciprocate | 100 times/minute |

| Stroke*Travel | Φ75mm×85mm |

| Maximum material diameter(EPS Particle ) | 6mm |

| Material consistency | ≥60mm |

| Hopper Volume | 140L |

| Main Driving Motor | Y2-114M-4 4Kw |

| Horizontal transport distance | 80m |

| Vertical delivery distance | 30m |

| Dimension(L*W*H) | 1940×895×960mm |

| Weight | 385kg |

| No. | Description | Qty. | Unit |

| 1 | LMP35/30 main unit | 1 | set |

| 2 | Conveying hose, ID38,length 10 meter | 1 | pcs |

| 3 | Spraying gun | 1 | pcs |

| 4 | Cleaning ball | 2 | pcs |

| 5 | Piston seal | 2 | pcs |

| 6 | Quick clamp rubber ring | 2 | pcs |

| 7 | Attachment tools | 1 | set |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

.jpg)

(Live chat)

(Live chat).jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS