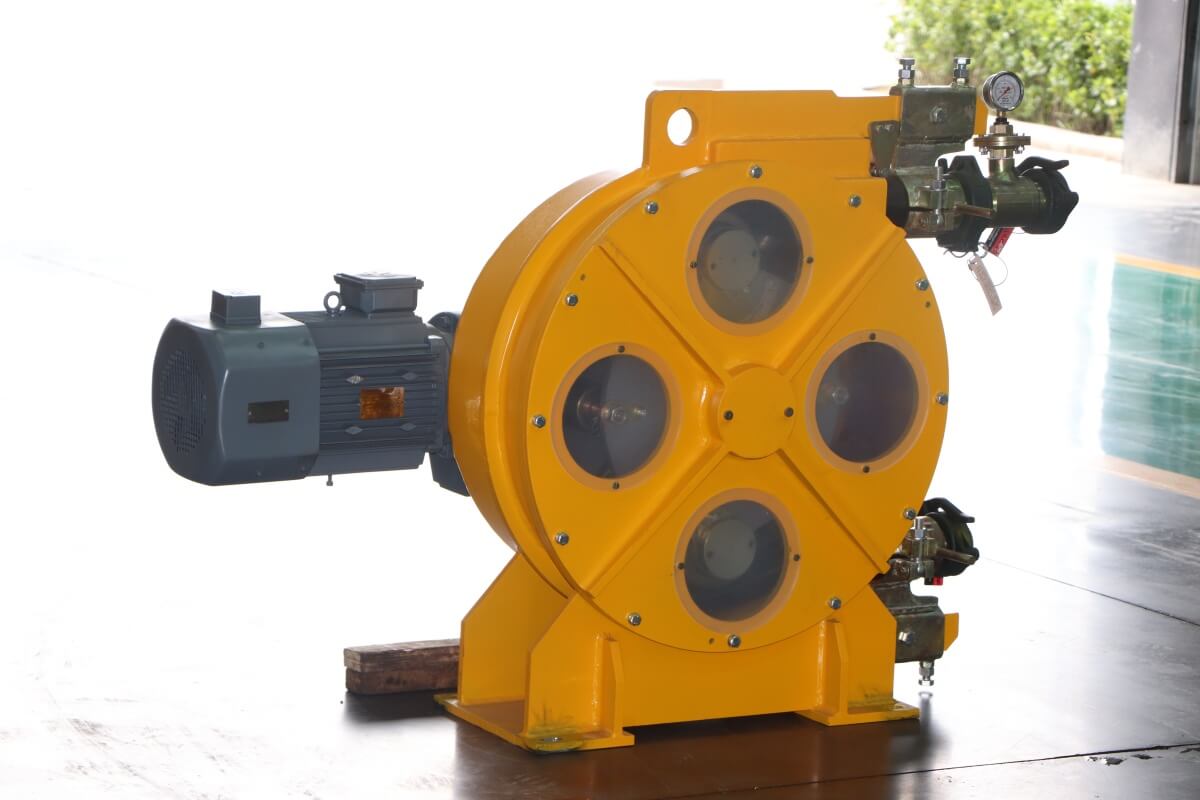

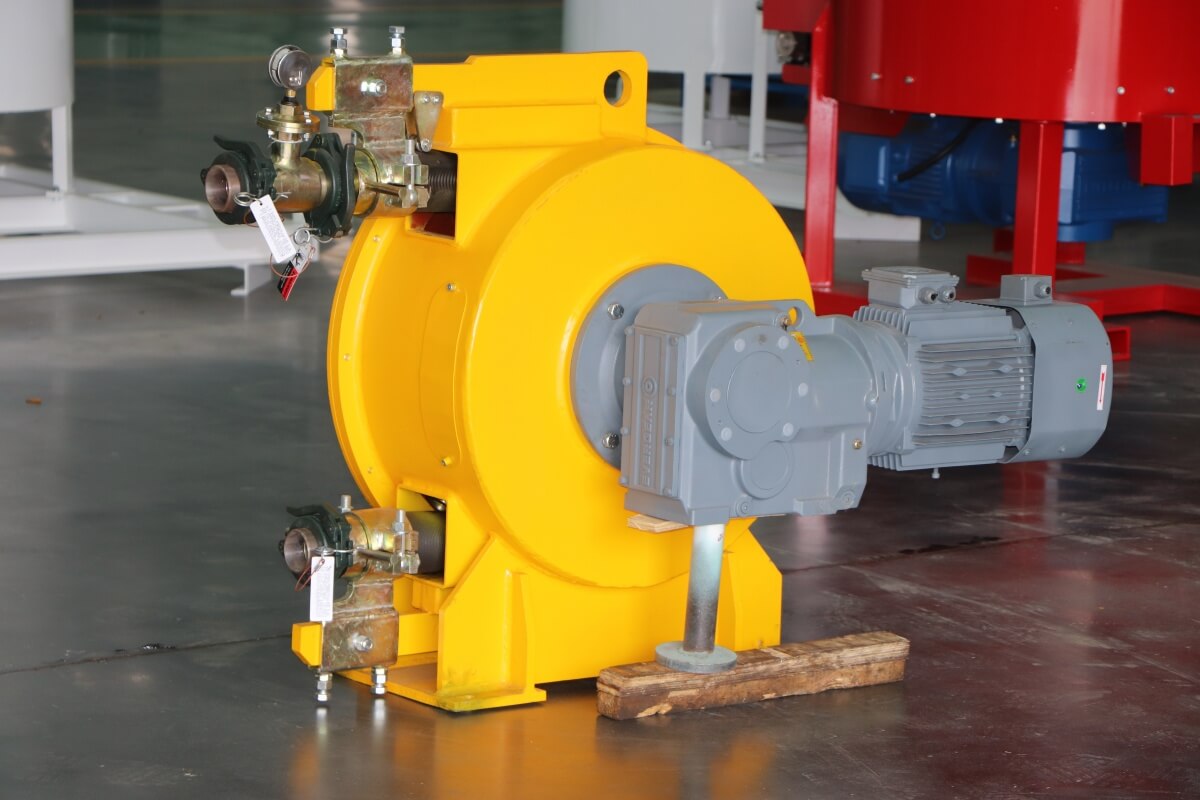

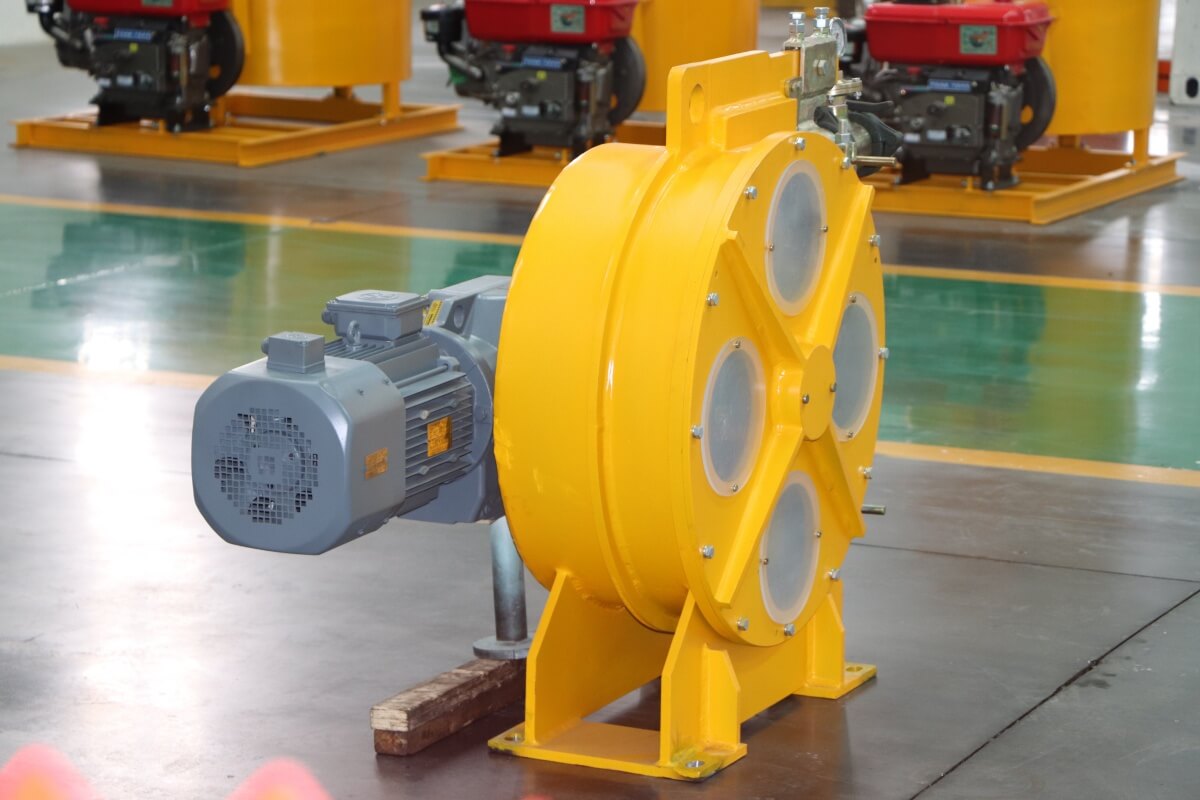

Peristaltic pumps for mine thickener discharge

Peristaltic pumps are successfully used in thickener discharge for:

Gold and silver leach plants (cyanide slurries)

Copper and base metal concentrators

Iron ore processing

Coal tailings management

Mineral sands and heavy media recovery

Advantages of Peristaltic Pumps for Thickener Discharge:

Excellent Handling of High-Solids, Viscous Slurries

Peristaltic pumps are positive displacement pumps that can handle thick, non-Newtonian slurries with ease.

They are not prone to clogging and can pass large particles and stringy materials without damage.

Capable of pumping high-density underflow directly from the thickener cone without dilution.

Superior Abrasion Resistance

The only part in contact with the slurry is the interior of the rubber hose.

Abrasive solids wear the hose, but this wear is predictable and contained.

The hose is a sacrificial, replaceable component, protecting expensive pump casings, rotors, or impellers (unlike centrifugal or screw pumps).

No Seals or Valves in Fluid Path

Eliminates leakage points and areas where slurry can dry out and seize—critical in thickener underflow, which can rapidly desiccate and block valves or clearances.

Self-Priming & Dry-Run Capable

Ideal for intermittent discharge cycles or when the thickener level fluctuates.

No damage if the pump runs dry momentarily.

️Reversible Operation

Can reverse flow to clear blockages in pipelines—a major advantage in long discharge lines prone to settling.

Corrosion Resistance

The fluid is isolated within the hose. Even in aggressive chemical environments (e.g., cyanide leach slurries, acidic tailings), the pump casing remains protected as long as the hose material is chemically compatible.

Precise Flow Control & Metering

Flow rate is linear with pump speed (RPM), enabling accurate control of discharge rate—useful for feeding filters, conveyors, or downstream processes.

Low Maintenance & Downtime

Hose replacement is typically quick (1–2 hours) and does not require alignment or complex reassembly.

No need to uncouple piping or drain the system in many designs.