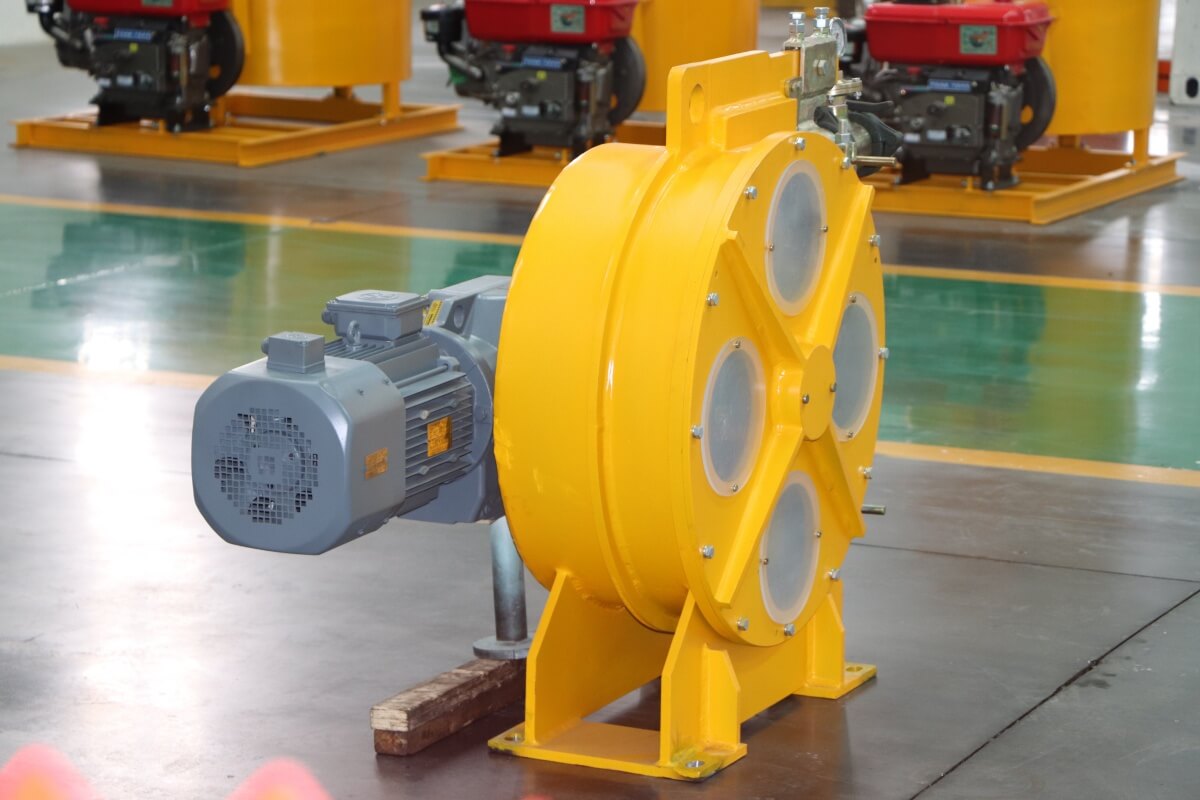

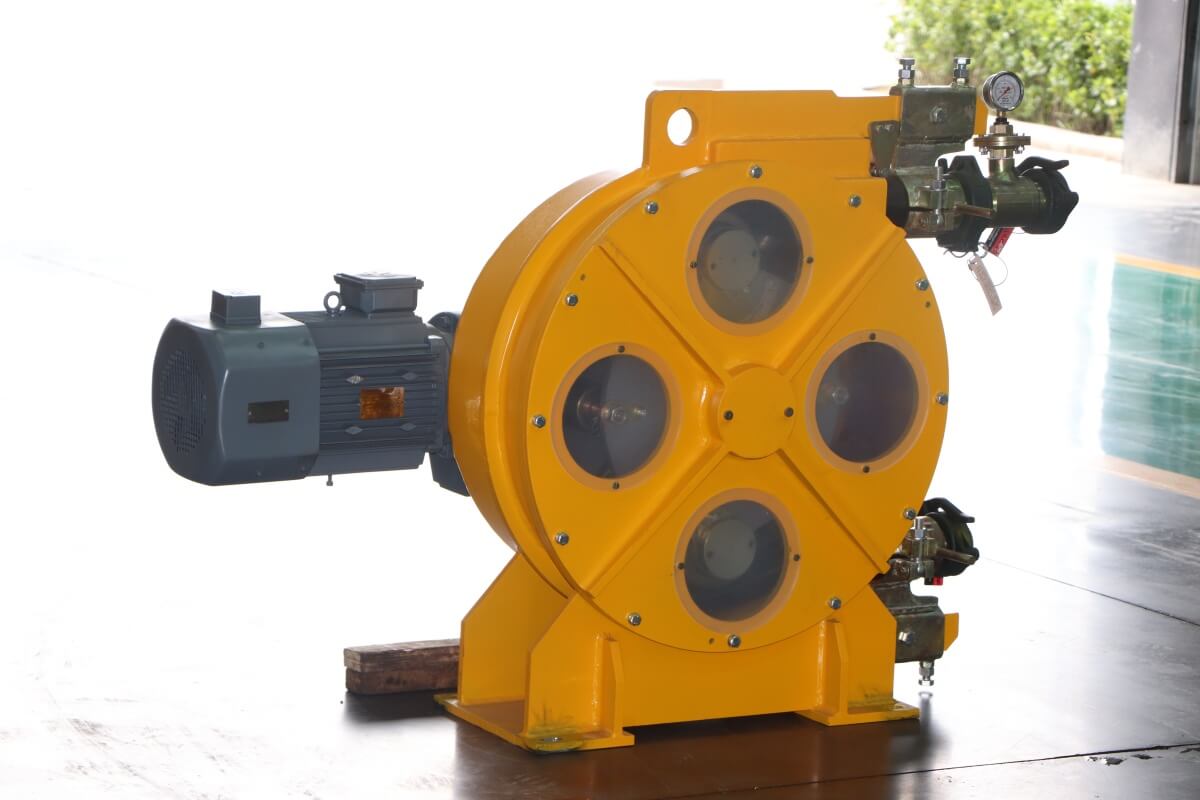

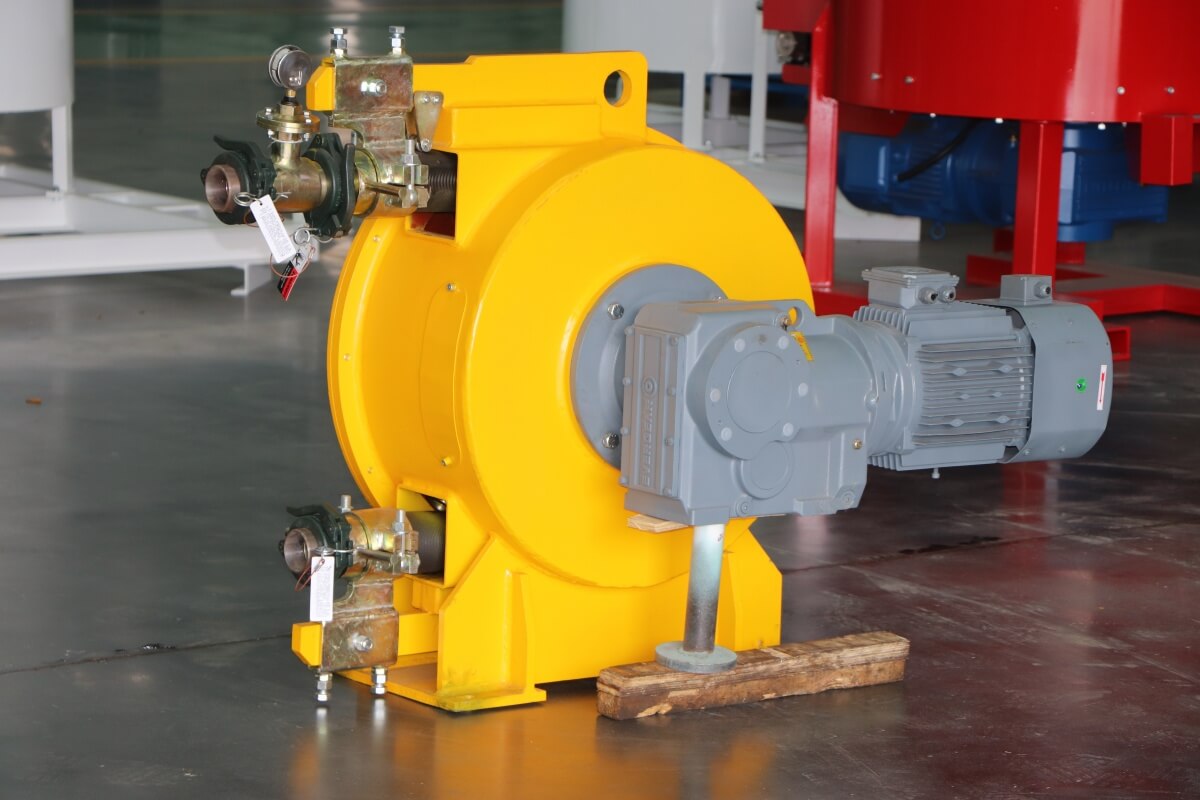

Peristaltic pump for pumping sludge with fines and brine

Peristaltic (hose) pump is a highly suitable and commonly used solution for pumping sludge containing fines and brine, especially in harsh or corrosive environments. This technology offers reliability, low maintenance complexity, and excellent chemical/abrasion resistance—making it a top contender for this challenging application.

When selecting a peristaltic pump for pumping sludge with fines (small abrasive particles) and brine (saline solution), several key factors must be considered to ensure efficient operation, durability, and minimal maintenance. Below is a structured guide to help you choose or configure the right pump:

1. Tube Material: Critical for Abrasion & Corrosion Resistance

The tube is the heart of a peristaltic pump and must withstand both abrasive fines and corrosive brine.

Recommended Materials:

EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to brine (saline environments) and good abrasion resistance for fine particles. Cost-effective for moderate abrasion.

Viton® (FKM): Superior chemical resistance (including concentrated brine) and moderate abrasion resistance. Ideal for aggressive brine or elevated temperatures.

Norprene®: Combines EPDM’s chemical resistance with a polypropylene lining for enhanced abrasion resistance. Suitable for sludge with sharp fines.

Silicone: Limited to mild brine (low salt concentrations) and low abrasion. Avoid for aggressive applications.

Tip: Thicker-walled tubes (e.g., 3–5 mm) reduce wear from fines. Regularly inspect and replace tubes to prevent leaks.

2. Pump Head Design: Minimizing Wear & Pulse

Roller Configuration:

Fewer Rollers (2–3): Reduces tube compression frequency, extending tube life for abrasive sludge. May increase flow pulsation.

More Rollers (4–6): Lowers pulsation but increases tube wear due to frequent compression. Prioritize if smooth flow is critical.

Bore Size: Match the tube’s inner diameter (ID) to the largest particle in the sludge (e.g., 10–20% larger than the maximum fine size to prevent clogging).

Housing Material: Stainless steel (316) or corrosion-resistant plastics (e.g., polypropylene) for brine compatibility.

3. Motor & Speed Control

Variable Speed Drive (VSD): Allows adjustment of flow rate (typically 0–200 RPM) to match sludge viscosity and particle load. Lower speeds reduce tube wear.

Torque: Ensure the motor has sufficient torque to compress the tube against the backpressure of the sludge (especially if thick or viscous).

4. Handling Particulates & Viscosity

Particle Size: Ensure the tube ID is ≥ 2x the largest fine size to avoid blockages. For example, 12 mm ID tube for 5 mm max particles.

Viscosity: Peristaltic pumps handle high viscosities (up to 10,000 cP) well, making them ideal for thick sludge. Brine (low viscosity) poses no issue.

5. Corrosion Protection for Wet Parts

Rollers/Bearings: Use stainless steel (316) or ceramic rollers with corrosion-resistant bearings (e.g., PTFE-coated) to prevent salt-induced seizure.

Seals/O-Rings: Viton or PTFE seals for brine compatibility.

6. Maintenance & Monitoring

Easy Tube Replacement: Quick-release pump heads simplify tube changes.

Tube Failure Detection: Optional sensors (e.g., pressure drop alerts) to prevent leaks.

Lubrication: Some pumps require periodic lubrication of rollers/bearings—opt for sealed, maintenance-free designs if possible.