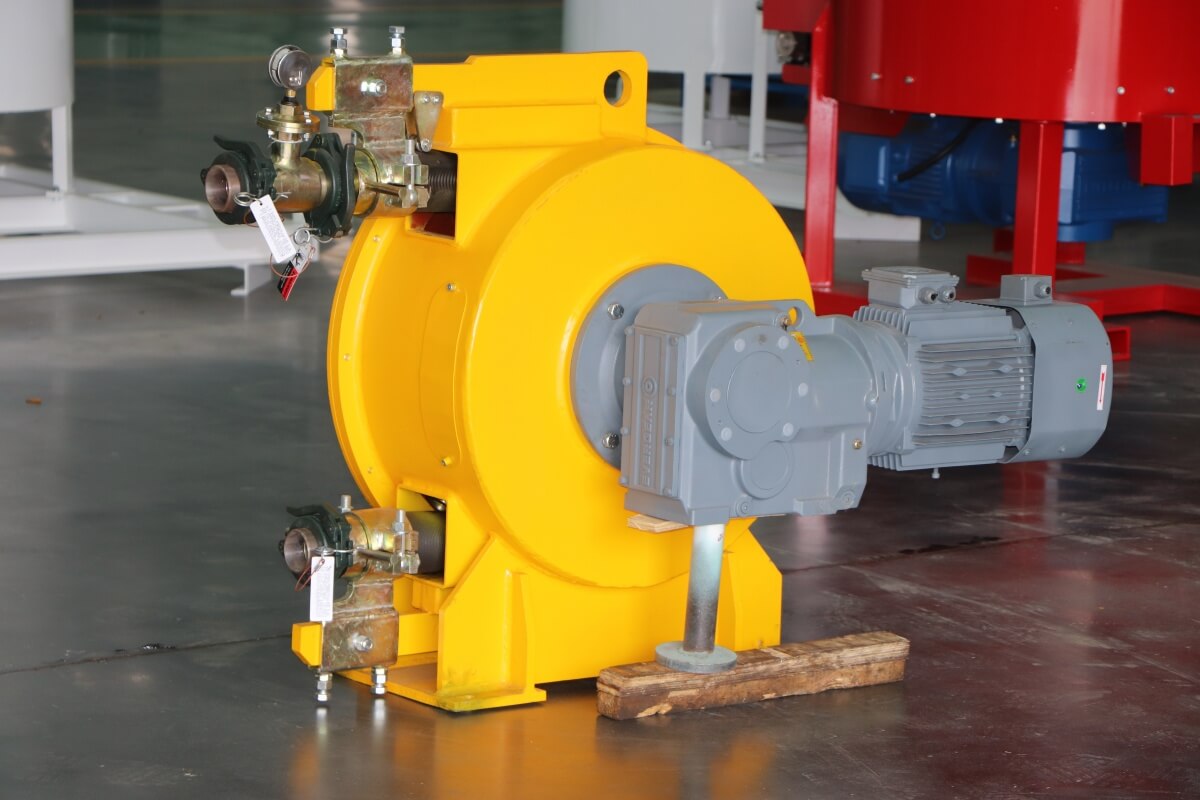

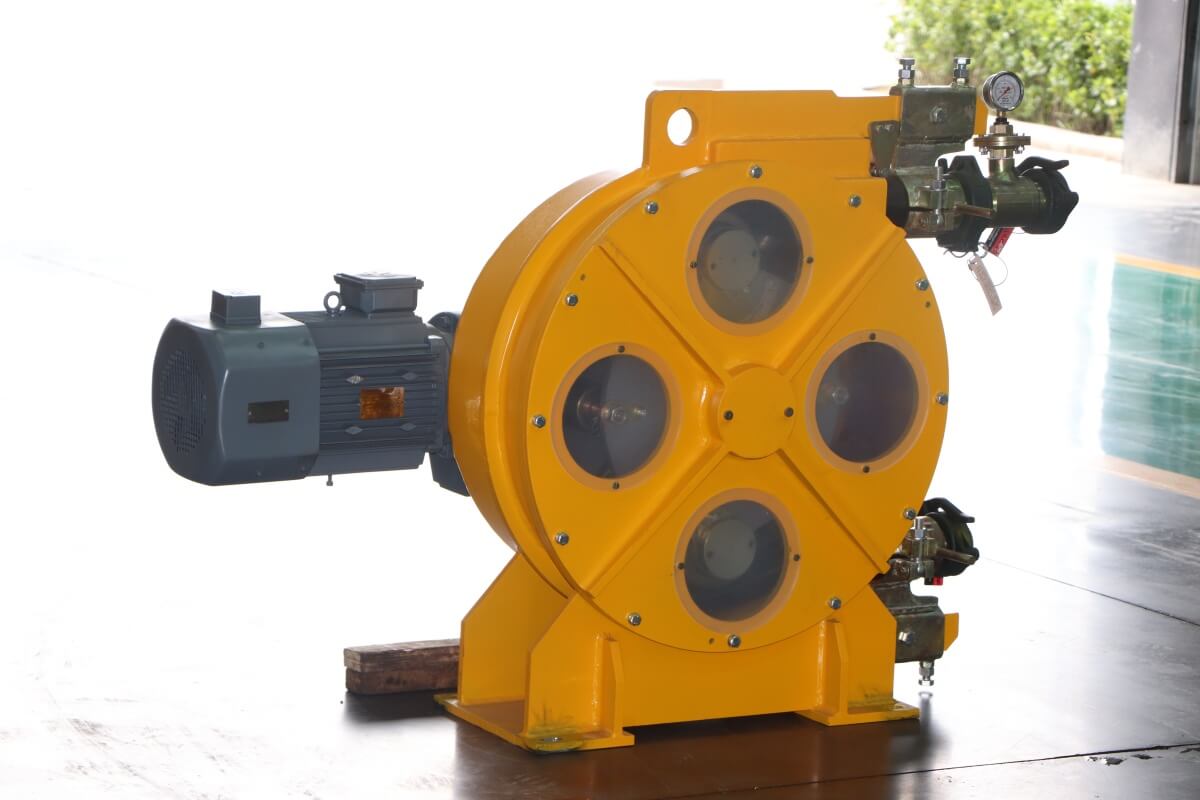

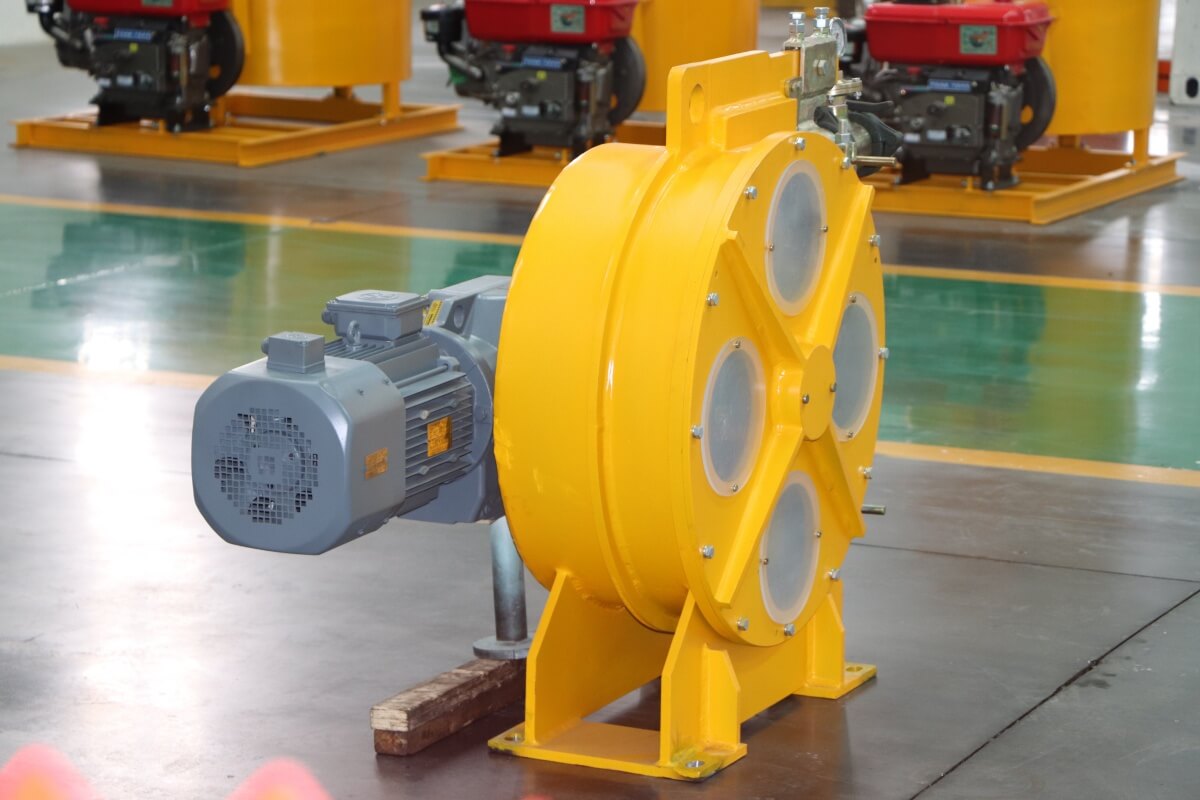

Wastewater Treatment Peristaltic Transfer Pump

A peristaltic pump is an excellent and widely used choice for wastewater treatment transfer applications, especially when handling challenging fluids like sludge, chemicals, scum, or abrasive/viscous slurries.

Why Peristaltic Pumps Excel in Wastewater Treatment?

Peristaltic (or hose/tube) pumps are positive displacement pumps that move fluid by mechanically compressing and releasing a flexible tube or hose. This design offers unique advantages in the harsh and variable environment of wastewater treatment:

1. Handles Abrasive and Solids-Laden Fluids

Wastewater often contains sand, grit, fibrous materials (rags, hair), and suspended solids.

Peristaltic pumps pass these materials without clogging or damage.

Only the interior of the tube/hose contacts the fluid, so abrasives wear the hose—not expensive internal components.

2. Self-Priming and Dry-Run Capable

Can start dry and prime automatically—ideal for intermittent duty or sump pumping.

No damage during dry operation (as long as not run dry for extended periods without cooling).

3. No Seals, Valves, or Clogging Points

Eliminates mechanical seals that can leak or fail due to grit.

No check valves or tight clearances that can clog with stringy solids—common in diaphragm or progressive cavity pumps.

4. Corrosion Resistant

The fluid is fully contained within the hose/tube.

Pump casing remains isolated from corrosive wastewater, hydrogen sulfide (H₂S), or chemical additives.

Choose chemically resistant tubing (e.g., EPDM, Norprene, PharMed) for compatibility.

5. Reversible Flow

Can reverse direction to clear pipeline blockages—very useful in long transfer lines.

6. Precise Flow Control & Dosing

Flow rate is linear with RPM—ideal for chemical dosing (e.g., polymers, acids, alkalis, biocides).

Excellent repeatability and accuracy for process control.

7. Low Maintenance & Easy Service

Maintenance is limited to hose/tube replacement, which is fast and does not require disassembling piping or drive components.

Reduces downtime and labor costs.

| Application | Why Peristaltic? |

|---|---|

| Raw Sewage Transfer | Handles rags, grit, and high solids without clogging. |

| Sludge Transfer (Primary, WAST, Digested) | Handles viscous, abrasive sludge; no seals to clog. |

| Chemical Dosing (Polymer, FeCl₃, NaOH, H₂SO₄, etc.) | Accurate metering; tubing resists chemicals. |

| Scum or Fat, Oil & Grease (FOG) Transfer | Handles viscous, stringy materials. |

| Leachate Transfer (Landfill) | Handles high-BOD, corrosive, and abrasive leachate. |

| Filter Press Feed | Positive displacement ensures consistent feed. |

| Digester Additive Transfer | Gentle on biological cultures; handles thick slurries. |