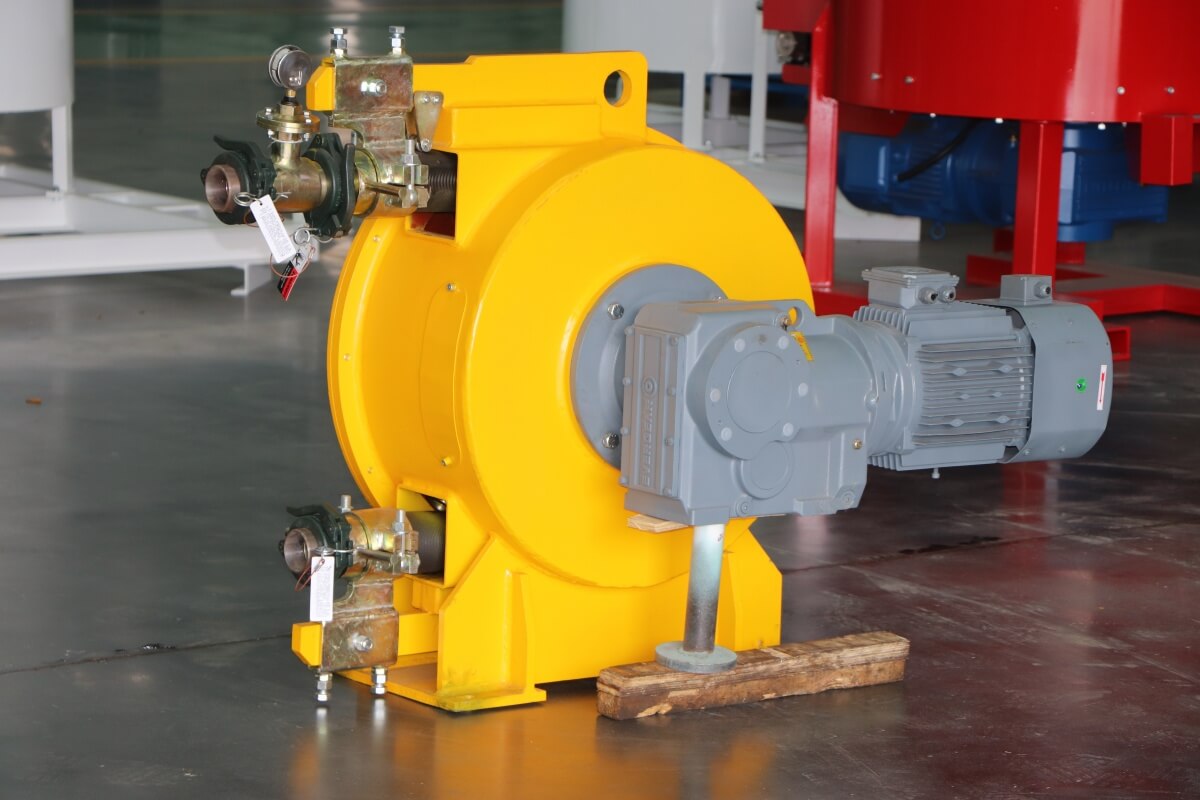

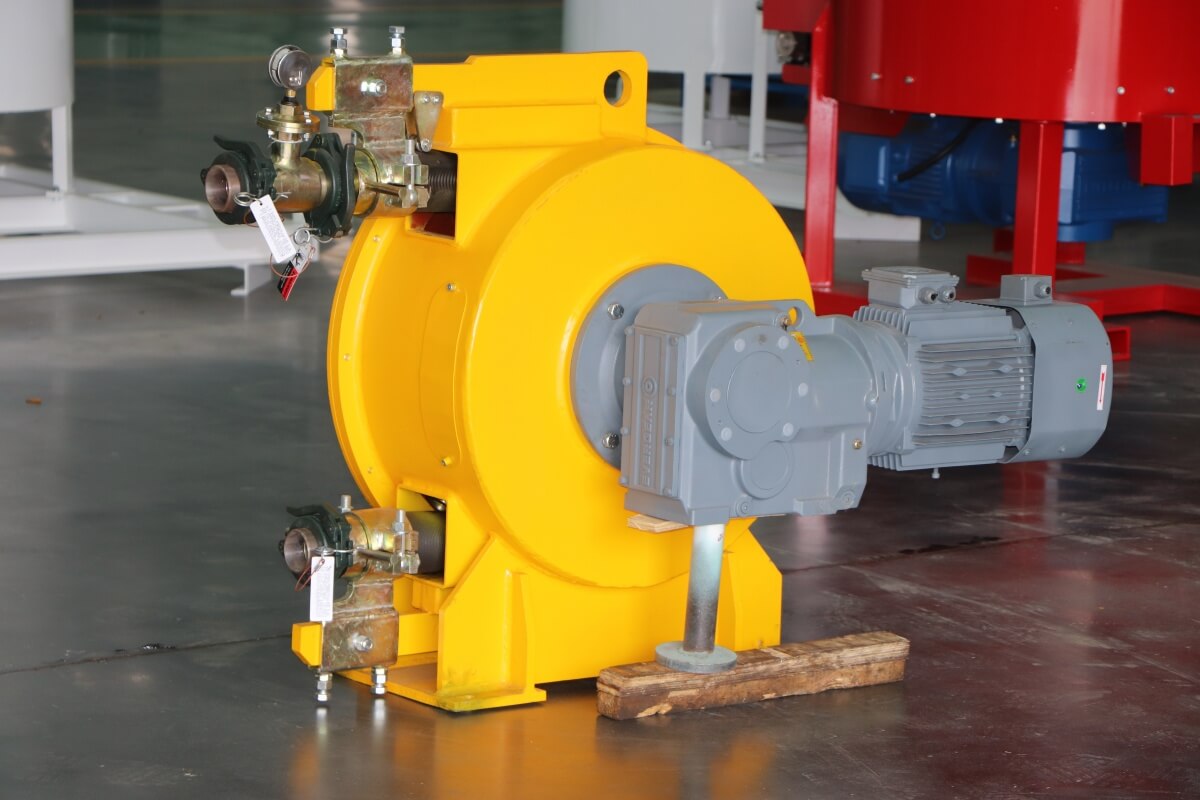

Peristaltic pump for ceramic slip transfer

Peristaltic pumps are very well-suited for many ceramic slip transfer applications, particularly where gentle handling, ease of maintenance, self-priming, and handling of abrasive slurries are priorities. Their main drawbacks are tubing wear (a consumable cost) and pressure/flow limitations compared to some other pump types (like progressive cavity pumps).

A peristaltic pump (also known as a hose pump or tube pump) can be an excellent choice for transferring ceramic slip, depending on the specific application requirements and slip characteristics.

Why Peristaltic Pumps Can Be Suitable for Ceramic Slip:

Gentle Handling: Peristaltic pumps move fluid by squeezing a flexible tube. This low-shear action is ideal for ceramic slips, which are often sensitive suspensions. It minimizes the risk of damaging particles or disrupting the carefully balanced slurry.

Self-Priming & Dry Running: They are excellent self-primers and can run dry without damage (as long as the tube isn’t overheated), which is useful for intermittent transfer operations or when starting with an empty line.

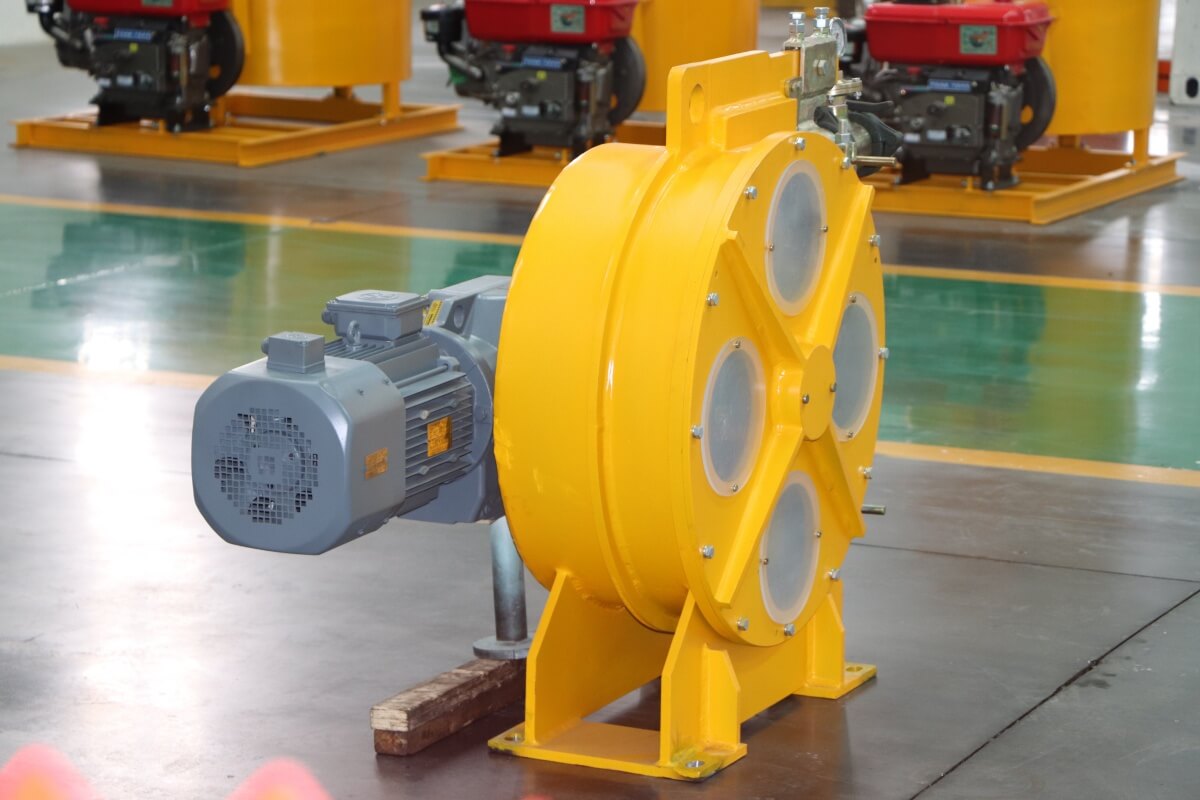

No Seals or Valves in Fluid Path: The only part contacting the fluid is the interior of the tubing. This eliminates potential leak points (seals) and areas where slip could harden and cause blockages (valves). This is a major advantage for abrasive or setting slurries.Reversible Flow: Simply reversing the pump direction reverses the flow, which is helpful for clearing lines or recovering material.

Accurate Metering (for Dosing): They provide excellent volumetric accuracy and repeatability, making them suitable for precise dosing applications (e.g., adding slip to a mold or adding additives to the slip).

Easy Maintenance & Cleaning: Maintenance is typically limited to replacing the tubing, which is quick and doesn’t require disassembling the pump head or dealing with complex internal parts exposed to the slip. Cleaning is often as simple as flushing the tube or replacing it.

Handles Abrasives Well (with correct tubing): While the tubing is sacrificial, modern abrasion-resistant tubing materials (like Norprene, PharMed BPT, or specific reinforced rubbers) can handle the abrasive nature of ceramic particles effectively. The wear is predictable and contained to the tube.