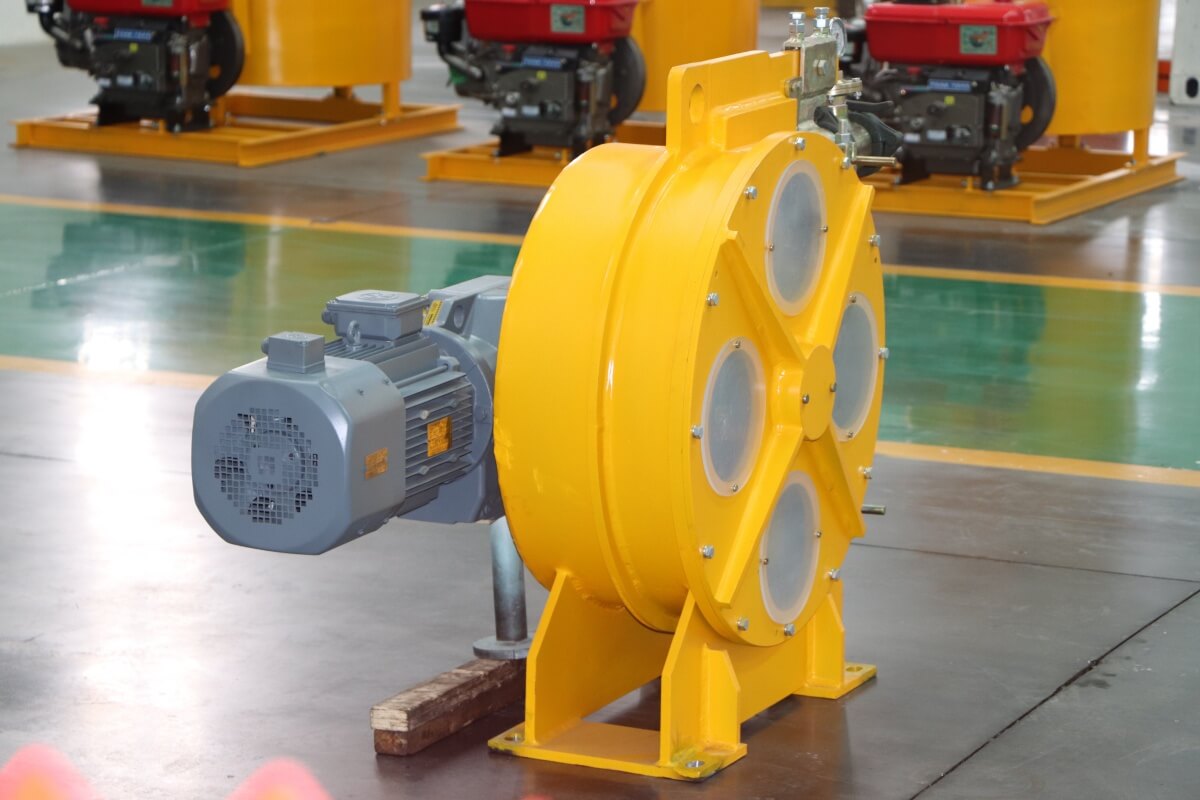

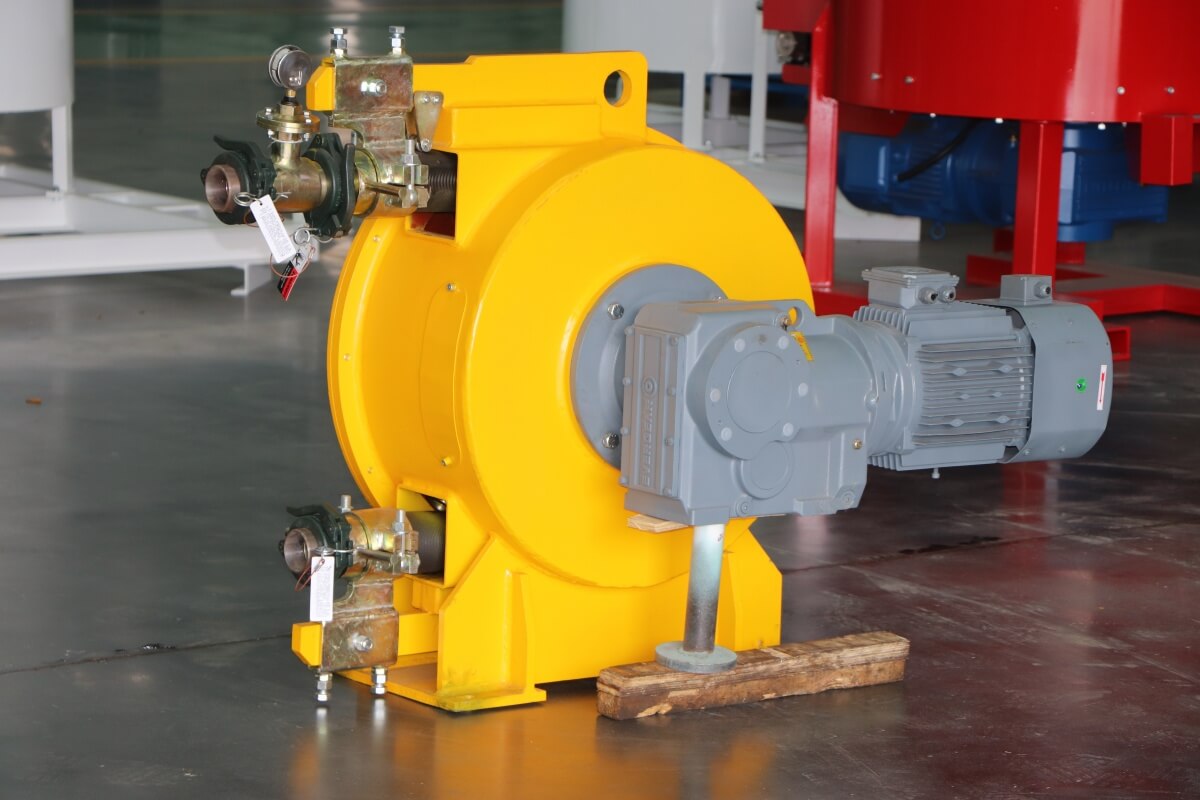

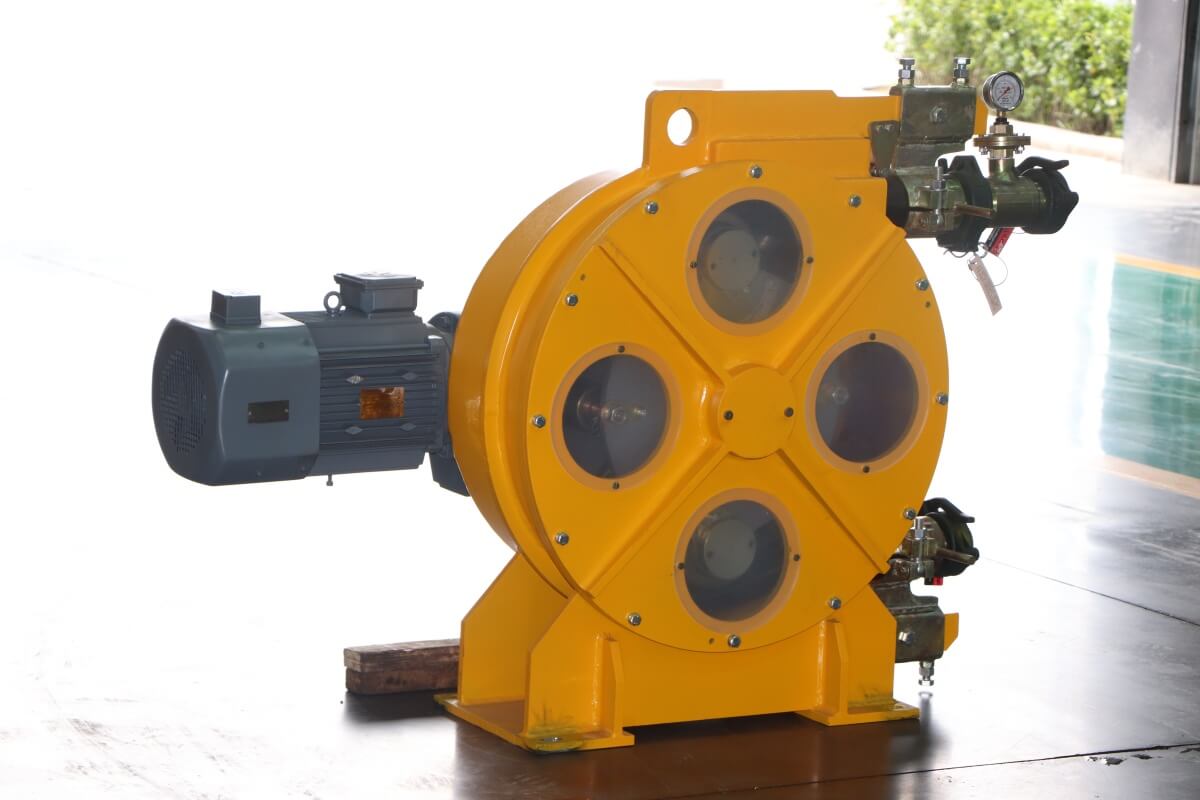

Squeesze type hose concrete pump

The squeesze type hose concrete pump is a special equipment that uses an extruded hose to transport concrete. Its core advantages are:

Simplified structure: Integrates mixing and pumping functions in one, reducing the equipment footprint and manual operation links;

Wear-resistant and long-life: Adopts high-strength hoses (such as imported Trelleborg materials), which increases the service life by 30% compared with traditional pumps and reduces replacement costs;

Strong adaptability: Can handle concrete with a maximum aggregate particle size of 15mm and a slump of 15-23cm, meeting the needs of secondary structural columns, tunnel linings and other scenarios;

Intelligent control: Supports variable frequency speed regulation and forward and reverse functions, can remotely monitor the operating status, and quickly eliminate pipe blockage faults.

Squeesze type hose concrete pumps are widely used in many fields such as construction, infrastructure, and industrial maintenance due to their compact structure, flexible transportation, and strong adaptability. The following is an analysis of its core application scenarios and specific advantages:

1. Construction field: from main construction to refined operations

Secondary structure casting

Scenario: Filling small spaces such as shear walls, structural columns, and ring beams with concrete.

Advantages: The hose can be bent to more than 90°, easily reaching indoor corners or stairwells. A single device can replace 3-5 workers, increasing efficiency by 50%.

High-rise building pumping

Scenario: Vertically transport concrete to buildings above 30 floors.

Advantages: Through the flexible bending characteristics of the hose, the use of relay pumps is reduced, the outlet pressure can reach 3MPa, and the vertical transportation height exceeds 80 meters.

Data: In a super-high-rise project, the energy consumption of the hose pump is reduced by 18% compared with traditional pumping equipment, and the pipe blocking rate is reduced by 60%.

Ground leveling and calendering

Scenario: Concrete laying on the ground of large-area factories and warehouses.

Advantages: Integrate mixing and pumping functions to achieve “mixing, conveying and paving” of concrete, reducing segregation problems caused by the transportation link.

2. Infrastructure field: Adapt to complex geology and working conditions

Tunnel and underground engineering

Scenario: tunnel lining, subway side wall pouring, mine support.

Advantages:

Explosion-proof equipment can adapt to gas environment, with a safety level of ExdI Mb;

The hose has strong wear resistance and can operate continuously for 200 hours without failure in sand and gravel concrete;

360° rotating arm design covers the full section of the tunnel.

Water conservancy and slope protection engineering

Scenario: reservoir dam, river slope protection, coastal embankment concrete pouring.

Advantages:

It can transport pebble concrete (maximum particle size ≤15mm) and adapt to complex geological conditions;

The hose has strong corrosion resistance and its life in seawater environment is 3 times that of traditional metal pipes.

Data: In a coastal slope protection project, the construction efficiency of the hose pump is 8 times higher than that of manual labor, and the cost is reduced by 65%.

Bridge and elevated construction

Scenario: pier casting, concrete filling inside box beams.

Advantages:

The squeesze type hose concrete pump is light (only 1.5 tons) and can be hoisted to the bridge deck by a tower crane;

The hose can pass through the steel mesh to achieve no dead angle casting.

3. Industrial maintenance and special scenarios

Equipment foundation grouting

Scenario: concrete casting of large machine tools, compressors, and wind power equipment bases.

Advantages:

The delivery pressure is precisely controllable (adjustable from 0 to 3MPa) to avoid segregation of the grouting layer;

The hose diameter has strong adaptability and can be connected to grouting pipes of different specifications.

Nuclear power and chemical anti-corrosion engineering

Scenario: anti-corrosion concrete spraying of nuclear power plant containment and chemical storage tank inner wall.

Advantages:

Explosion-proof motor and static pressure seal design meet ATEX Zone 1 explosion-proof standards;

Special concrete with added anti-corrosion materials such as glass flakes and polymers can be transported.

Data: According to actual measurements of a nuclear power project, the uniformity error of the hose pump spraying thickness is ≤5%, which is 10 times higher than the efficiency of manual spraying.

Emergency rescue and post-disaster reconstruction

Scenario: cleaning up ruins after an earthquake, repairing roads damaged by floods.

Advantages:

The squeesze type hose concrete pump can be quickly disassembled and assembled, and the transfer can be completed in 4 hours;

The diesel power option is suitable for areas without power grids, with a battery life of up to 8 hours.

IV. Overseas export and customized needs

Voltage and power adaptation

In view of the unstable power grid in Southeast Asia, Africa and other regions, a 110V-480V wide voltage design is provided, which supports direct connection of diesel generators.

Multilingual control system

The exported equipment is equipped with 10 language operation interfaces including Chinese/English/French/Spanish, reducing the cost of overseas worker training.

Data: According to feedback from a Middle East project, the multilingual system shortens the time it takes to get started with the equipment from 7 days to 2 days.

Modular design and transportation optimization

The squeesze type hose concrete pump is disassembled into modules ≤2 meters, suitable for 20-foot container transportation, reducing the cost of sea transportation by 30%.