Squeeze concrete pump manufacturer

We are industrial peristaltic hose pump manufacturer and supplier for many years and can provide various types of hose pumps. Squeeze concrete pumps are widely used in high-rise buildings, tunnels, water conservancy and other projects and are famous for their low energy consumption and high reliability.

Leadcrete Equipment can provide you with various types of hose pumps. The recently developed squeeze concrete pump is equipped with a mixer and is a machine specially customized for customers.

Core Analysis of Squeeze Concrete Pump

1. Technical Principle and Structural Features

Working Principle

Concrete delivery is achieved by rotating the roller to squeeze the rubber hose, similar to the action of “squeezing toothpaste”:

Pressure delivery stage: The roller squeezes the front end of the hose to squeeze out the concrete.

Suction stage: When the hose recovers, a local vacuum is formed to suck in new concrete.

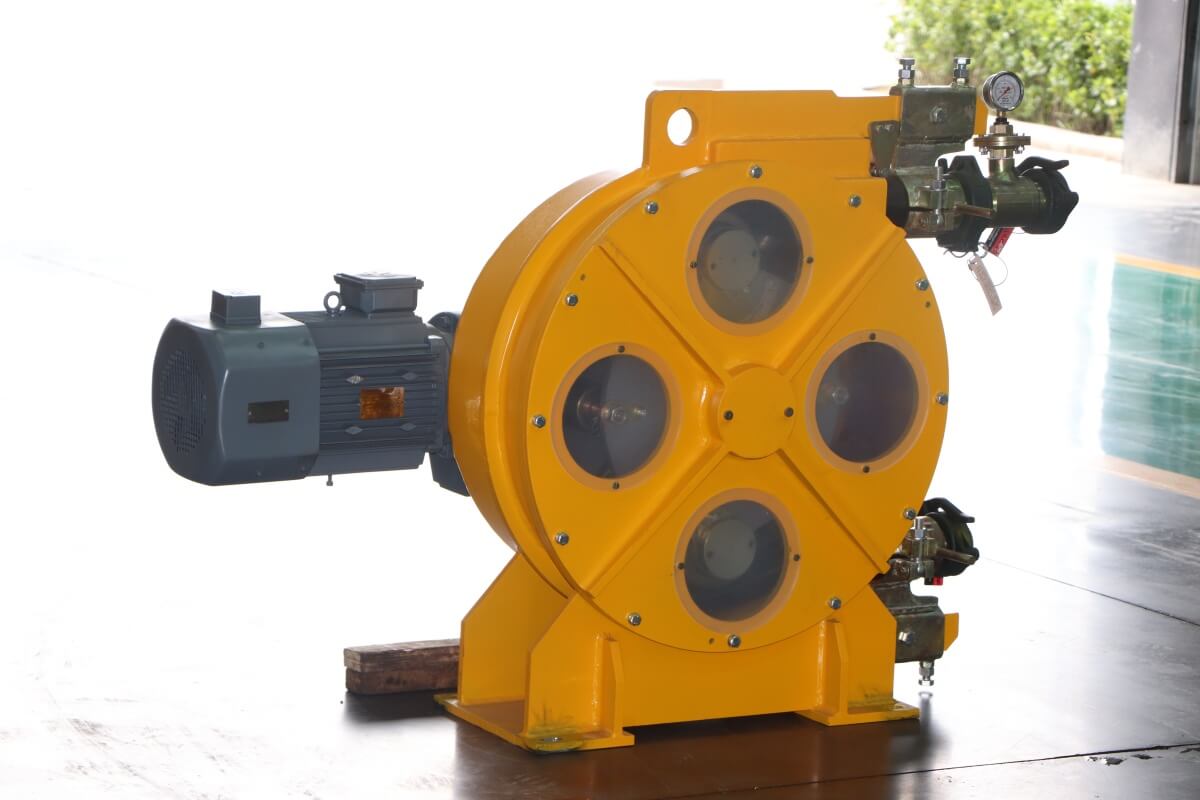

Continuous delivery is achieved through reciprocating cycles, and the vacuum negative pressure system assists in improving the suction efficiency.

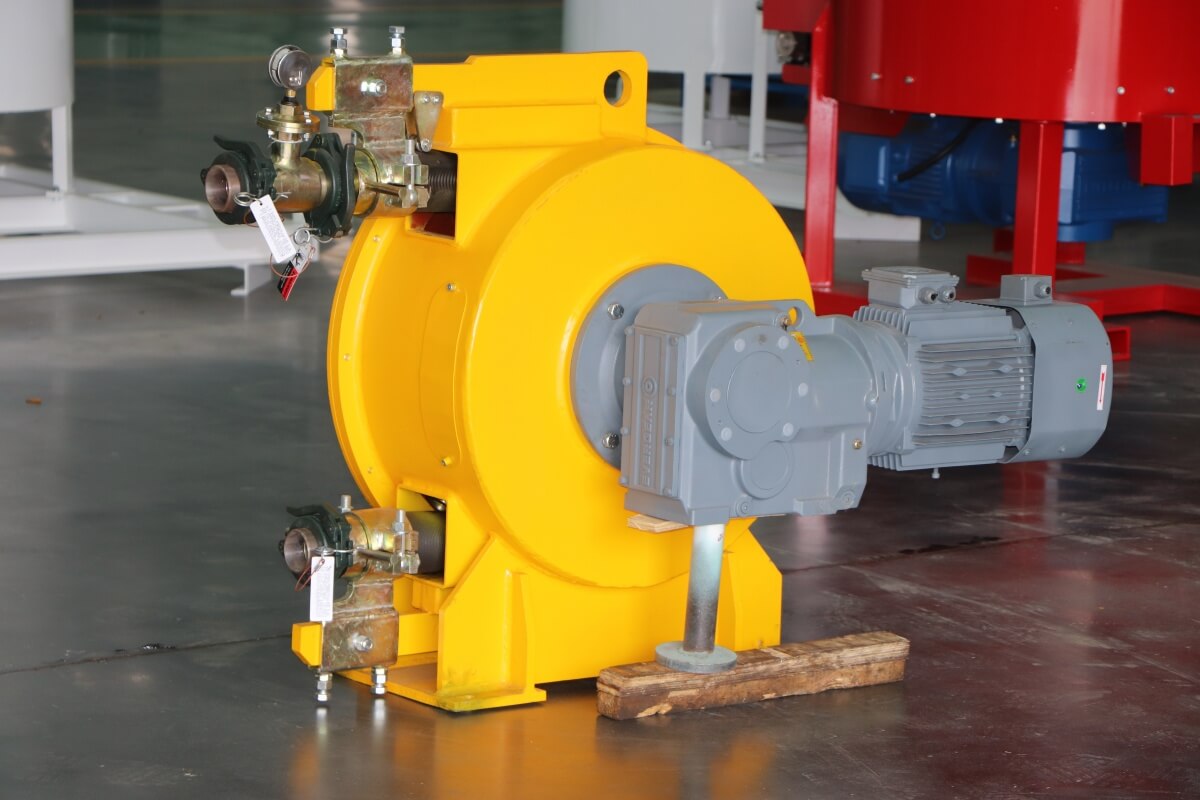

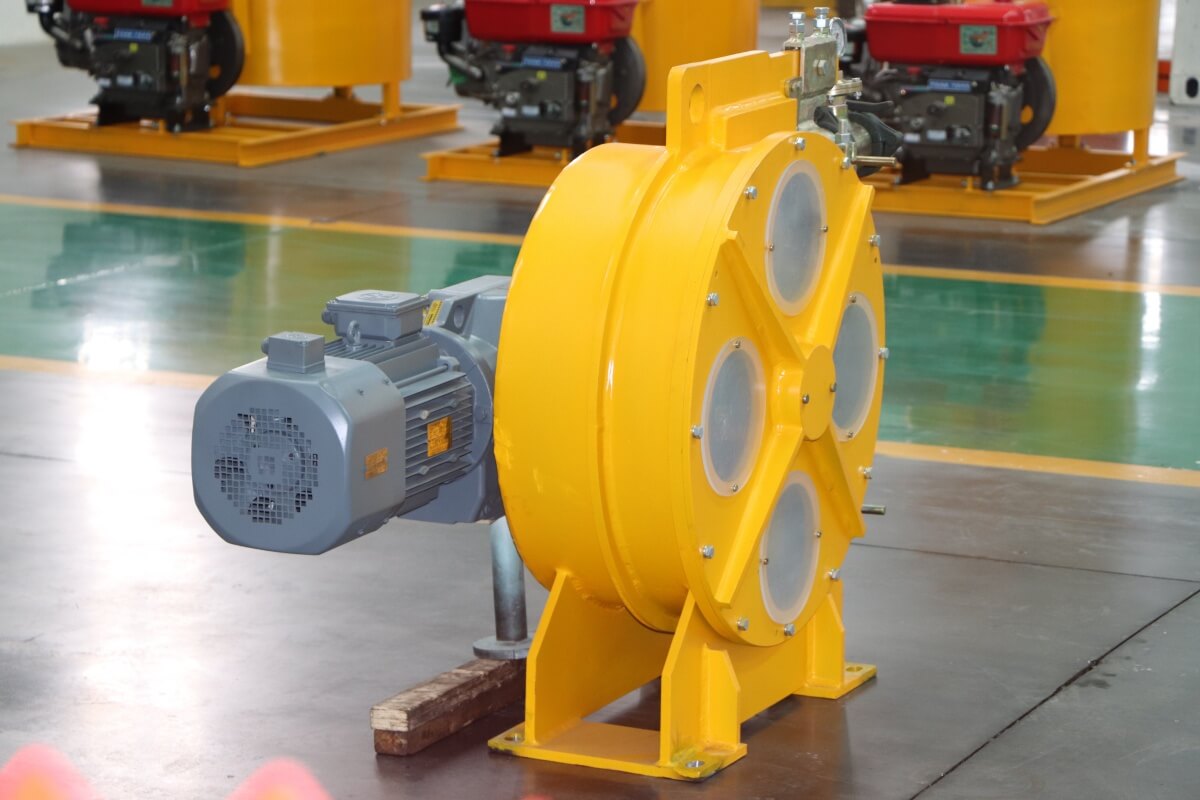

Core Components

Pump body: sealed structure, built-in roller frame and rotor transmission device;

Squeeze hose: high elastic rubber material, direct contact with concrete;

Drive system: planetary roller rotation mechanism, providing continuous extrusion power;

Vacuum system: assists hose recovery and reduces suction resistance.

Technical parameters

Displacement: usually 15-60m³/h, affected by the rotor radius, rotation speed and hose diameter;

Pressure: working pressure 2-3MPa, vertical conveying height can reach 80 meters;

Aggregate particle size: ≤15mm, suitable for fine stone concrete conveying;

Slump: 15-23cm, high fluidity requirements.

2. Technical advantages and limitations

Advantages

Simple structure: low difficulty in component processing, manufacturing cost is 30%-50% lower than that of piston pumps;

Long life: only the hose is a vulnerable part, other parts do not directly contact the concrete, and maintenance costs are reduced by 40%;

Strong flexibility: the hose can be bent to more than 90°, suitable for narrow space operations (such as indoor secondary structure casting);

Reverse operation function: reverse rotation can eliminate blockage, and fault handling efficiency is increased by 50%.

Limitations

Low delivery efficiency: The displacement is usually smaller than that of a piston pump, which is not suitable for large-scale continuous construction;

Limited pressure: The maximum delivery distance is about 200 meters (horizontally), and the vertical delivery height is limited;

Strict requirements for aggregates: Too large a particle size can easily clog the hose, and the concrete mix ratio needs to be strictly controlled.

3. Typical application scenarios

Construction field

Secondary structure casting: Filling small spaces such as shear walls and structural columns, a single device replaces 3-5 workers;

Ground leveling: Integrate mixing and pumping functions to achieve “mixing, conveying and paving” of concrete.

Infrastructure field

Tunnel lining: 360° rotating boom design, covering the entire section of the tunnel;

Slope protection engineering: Transporting pebble-containing concrete (particle size ≤15mm) to adapt to complex geological conditions.

Industrial maintenance

Equipment foundation grouting: Accurately control the grouting pressure to avoid segregation of the equipment base;

Anti-corrosion engineering: Transport special concrete with added glass flakes to meet the anti-corrosion needs of chemical storage tanks.