Peristaltic pump for pumping mortar

When selecting a peristaltic pump for pumping mortar (a thick, abrasive mixture of cement, sand, and water), the focus must be on abrasion resistance, pressure handling, and durability to manage the challenges of mortar’s viscosity, particle size, and alkaline nature.

Key Considerations for Peristaltic Pumps in Mortar Transfer:

Tube Material (Critical for Abrasion and Chemical Resistance)

Mortar contains sharp sand/cement particles (often 1–5 mm) and is alkaline (pH 12–13). Tubes must resist both abrasion and chemical degradation:

Recommended Materials:

Polyurethane (PU): High abrasion resistance, ideal for coarse particles.

EPDM Rubber: Excellent resistance to alkalines (cement) and moderate abrasion.

Natural Rubber: Good abrasion resistance but may degrade in alkaline environments over time.

Hypalon® (CSM): Superior chemical resistance to alkalines and abrasion (costlier).

Avoid silicone or PVC, which wear quickly under abrasion and fail in alkaline conditions.

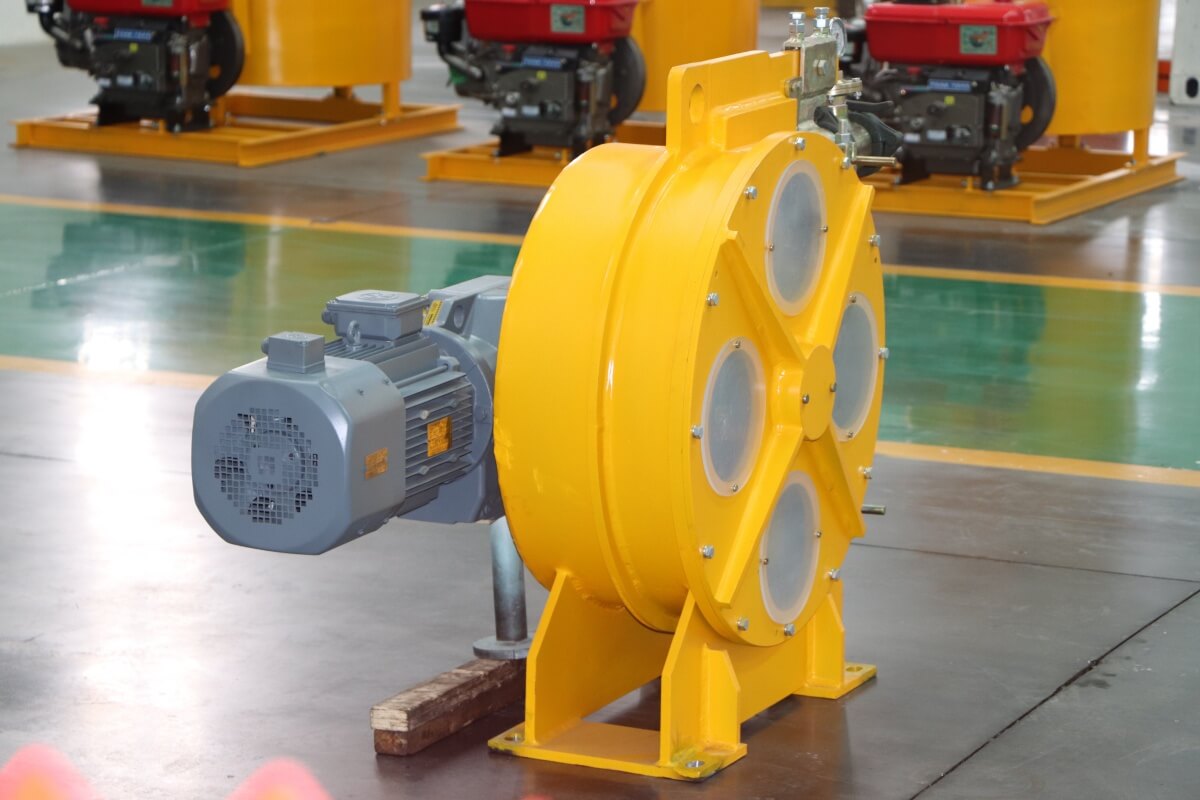

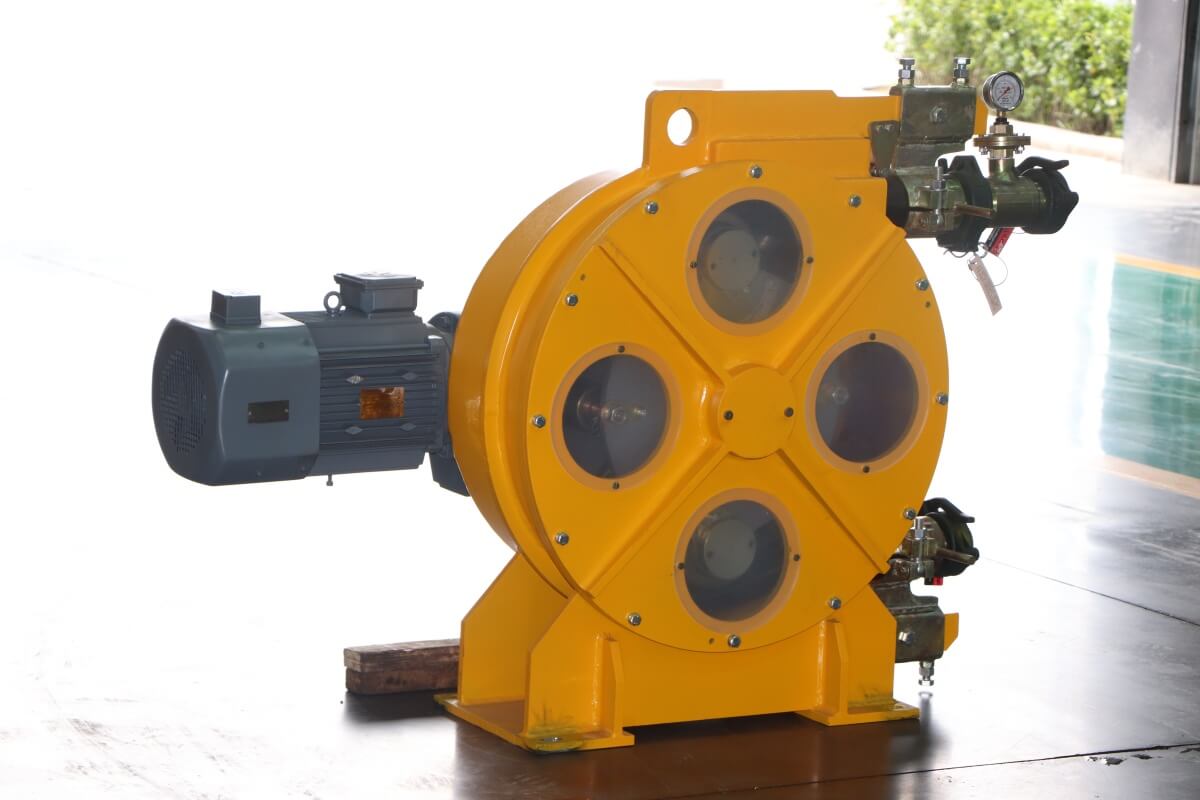

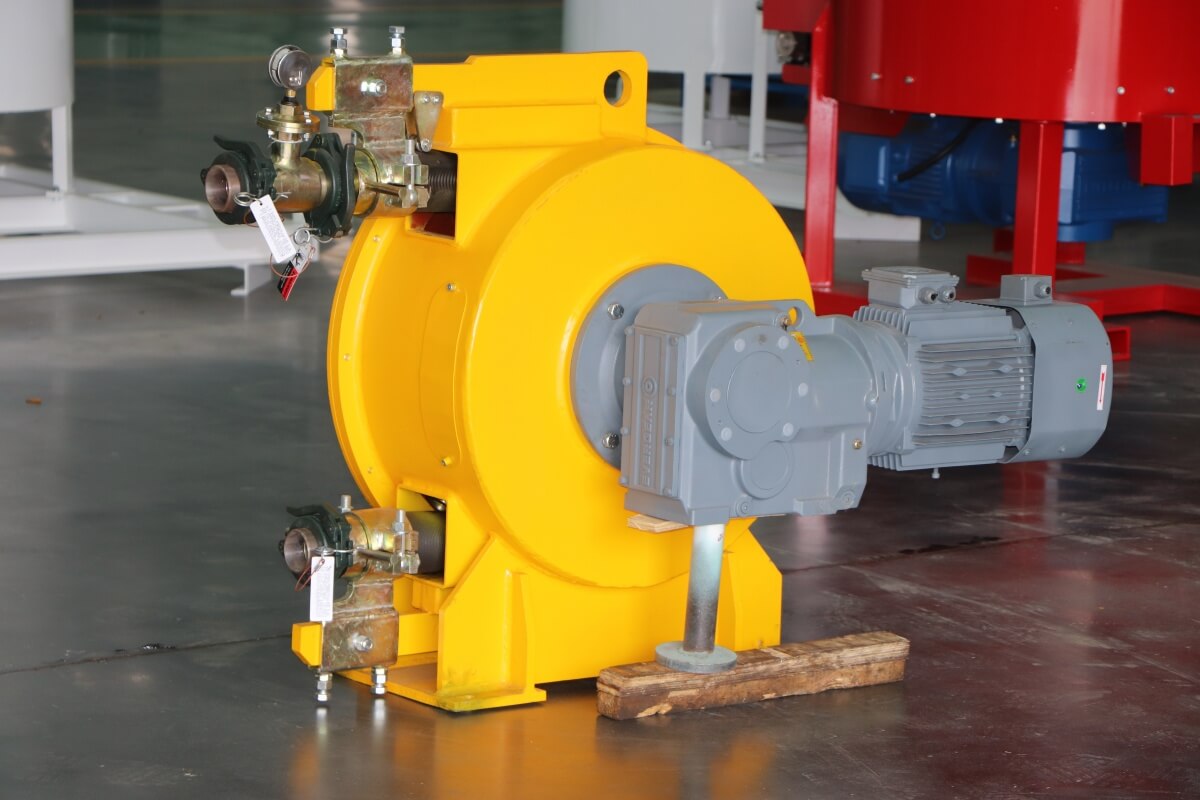

Pump Head Design

Roller Count: Use 4–6 rollers to distribute compression forces evenly, reducing tube wear and pulsation.

Occlusion: Ensure full occlusion of the tube to prevent backflow, especially with viscous mortar.

Easy Tube Replacement: Look for hinged pump heads or quick-release clamps to minimize downtime during tube changes.

Flow Rate and Pressure

Flow Rate: Mortar applications (e.g., grouting, masonry) typically require 5–50 L/min. Match pump RPM and tube ID to target flow.

Pressure Rating: Mortar systems often require high pressure (e.g., 10–20 bar for spraying or vertical pumping). Select pumps rated for ≥10 bar (industrial peristaltic pumps can reach 15–25 bar).

Viscosity and Particle Size Handling

Viscosity: Mortar viscosity ranges from 2,000–10,000 cP. Ensure the pump has high torque to avoid slipping.

Particle Size: Tubes must have an ID ≥3x the largest particle size (e.g., 10–15 mm ID for 5 mm particles) to prevent clogging.

Gentle Compression: Avoid excessive compression that could crush particles (which thickens mortar).

Chemical Compatibility

Cement is highly alkaline. Tubes must resist degradation from calcium hydroxide and other alkaline compounds. EPDM and Hypalon are optimal; test compatibility if using additives (e.g., accelerators).

Maintenance and Downtime

Tube Lifespan: Mortar shortens tube life (replace every 50–200 hours, depending on usage). Monitor wear via flow rate drops or visible thinning.

Cost of Consumables: EPDM/Hypalon tubes are pricier but last longer than PU in alkaline environments. Balance upfront cost with downtime savings.