Hose concrete pump with mixer

Hose concrete pump with mixer is an integrated design of mixing and pumping, which reduces equipment transfer time and improves construction continuity. It can transport materials containing solid particles (maximum particle size < 1/4 of the hose inner diameter), high viscosity, and shear-sensitive materials. The flow rate is stable, and the re-measured volume accuracy is ±1%, which supports laboratory-level measurement requirements. The hose is the only consumable part, and the replacement cycle is long.

The hose concrete pump with mixer is a device that integrates concrete mixing and hose pumping functions. Its core features include:

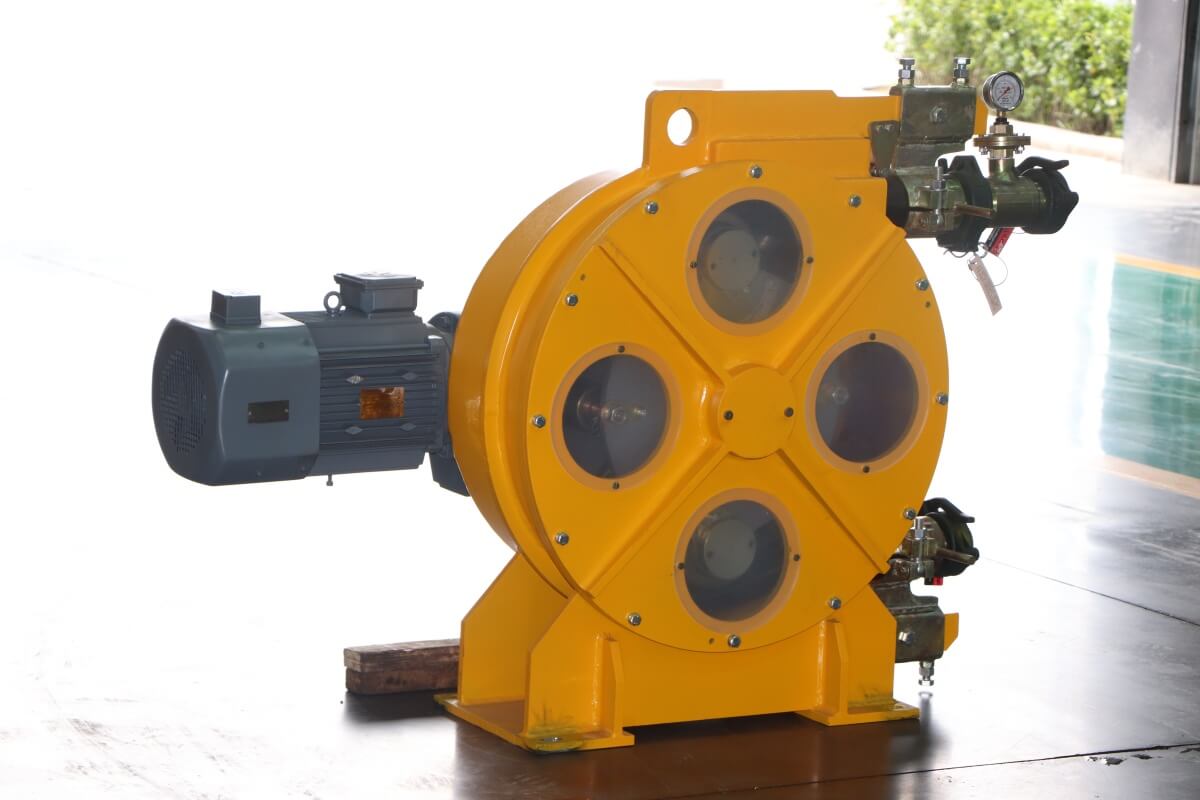

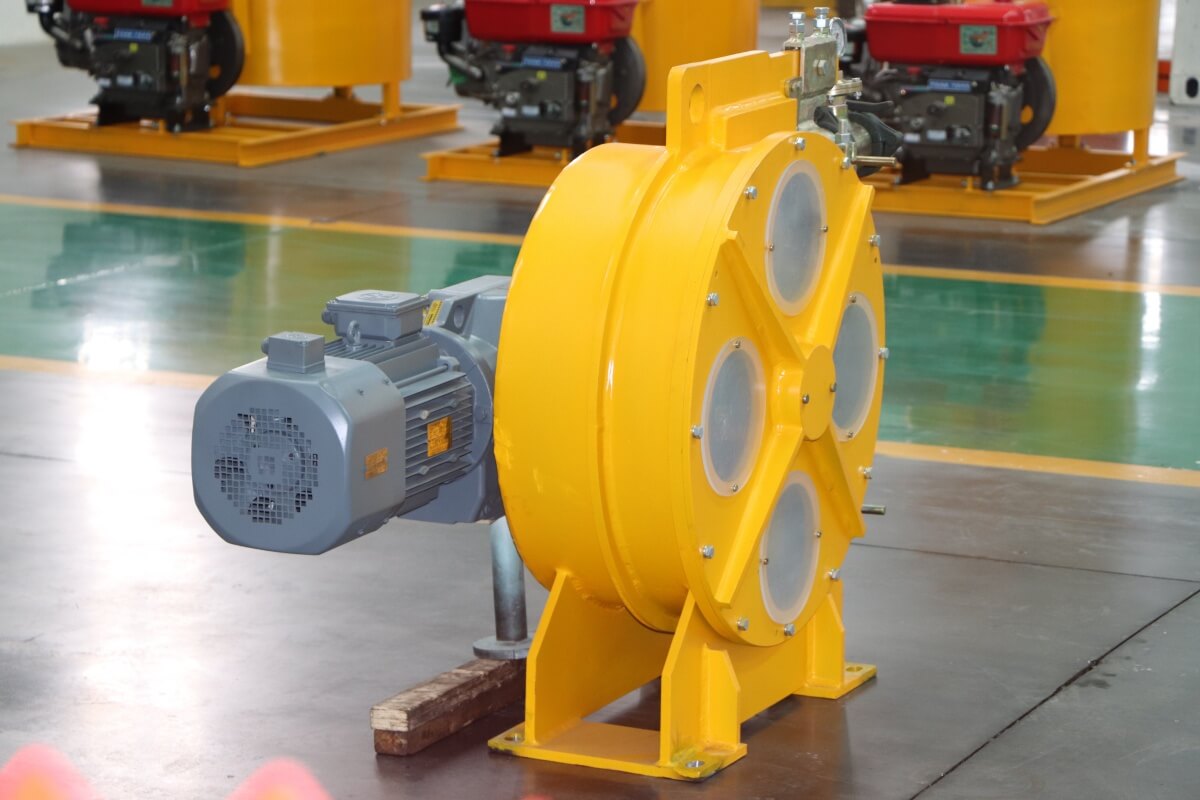

Hose pumping system: Concrete transportation is achieved by squeezing the elastic hose through rollers or sliders, without mechanical seals, avoiding leakage risks.

Integrated mixing design: Equipped with a forced mixing device, it can mix concrete on site and pump it directly, reducing intermediate links and improving construction efficiency.

Self-priming and dry operation capabilities: Vacuum suction is generated when the hose recovers its deformation, supporting idling operation and adapting to complex working conditions.

Typical application scenarios of hose concrete pump with mixer:

Construction field: secondary structural column casting, floor heating backfill, and narrow space concrete transportation.

Industrial field: mine filling, tunnel lining, refractory material transportation.

Special working conditions: flammable and explosive environment (pneumatic motor model), radioactive waste liquid treatment.