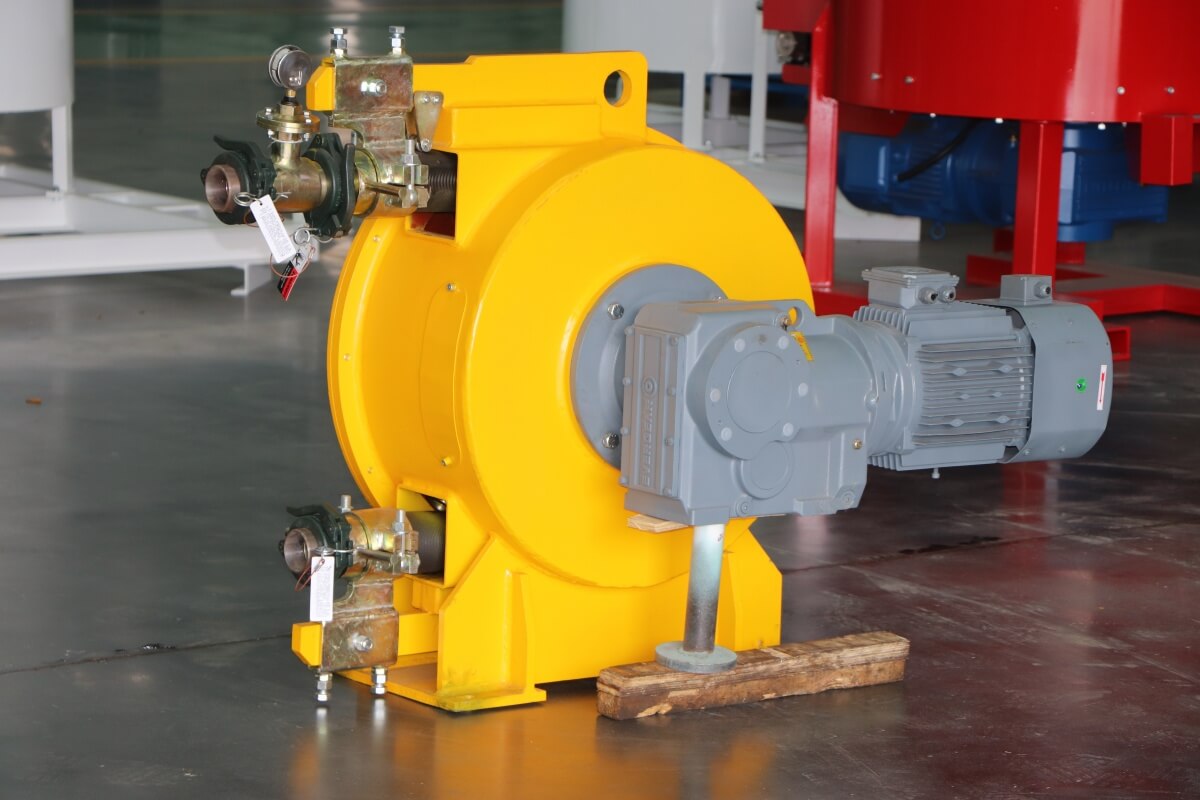

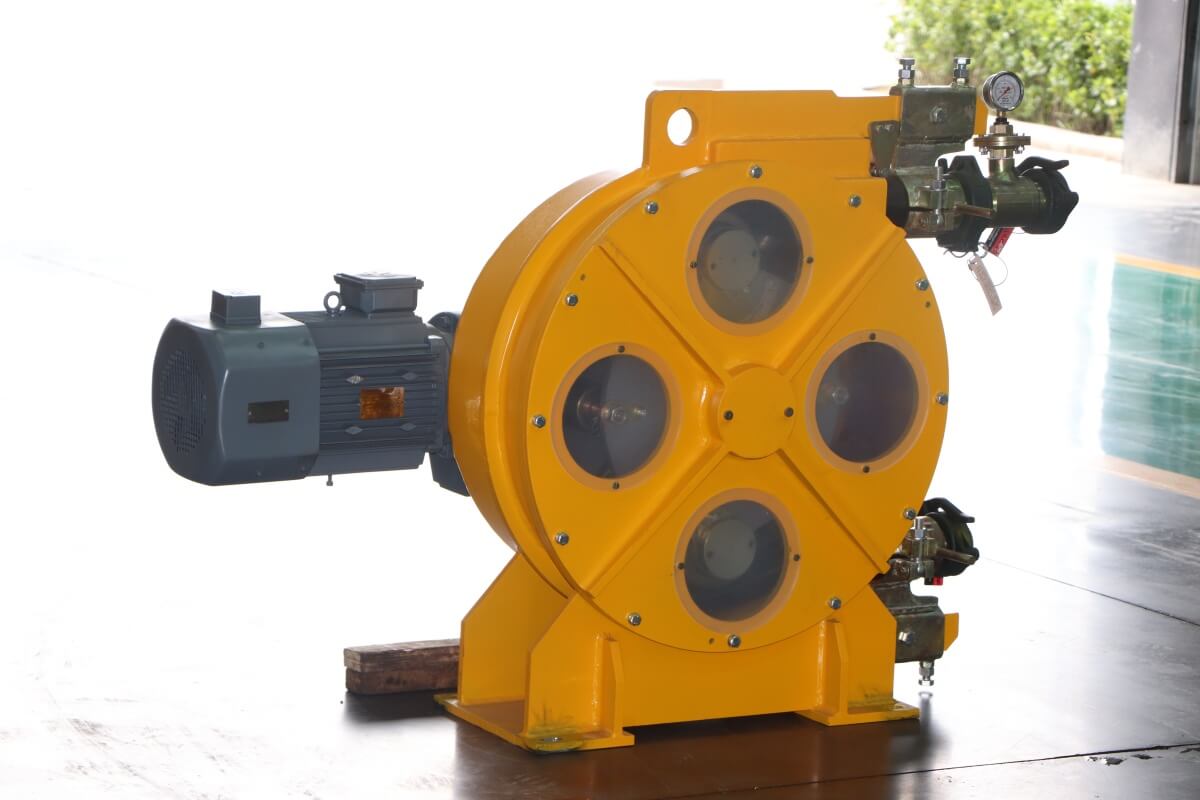

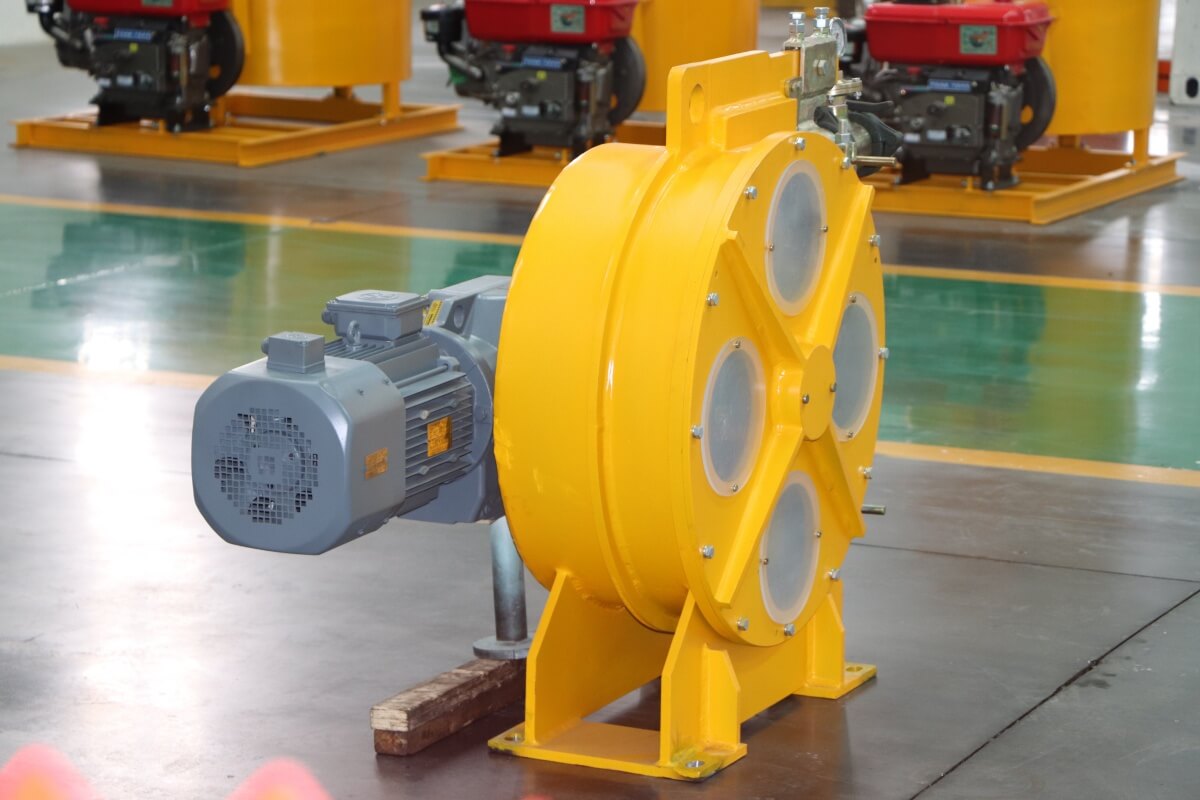

Hose peristaltic transfer pump

Hose peristaltic transfer pump ideal applications:

A hose peristaltic pump excels in scenarios where traditional piston or screw pumps struggle:

Specialty & Confined Space Placement: Pumping into narrow forms, complex geometries, or tight access areas where maneuvering a traditional pump’s boom/pipe is difficult.

Grouting & Anchoring: Pumping cementitious grouts, micro-piles, soil stabilization, and rock annotation.

Concrete Repair & Refurbishment: Mortars, shotcrete (when equipped with an acceleration nozzle), resurfacing materials, and patch repairs.

Precast & Architectural Concrete: Smaller-scale production of countertops, panels, and decorative precast elements.

Fiber-Reinforced Concrete (FRC): Handles fibers significantly better than piston pumps prone to valve clogging.

Low-Volume Projects: Jobs where the high setup cost and complexity of a large piston pump aren’t justified.

Abrasive/Corrosive Mixes: Applications where component wear from abrasive aggregates or corrosive additives is a major concern.

A hose peristaltic transfer pump is a specialized positive displacement pump designed to reliably transfer challenging materials like concrete, grout, mortar, slurry, or other viscous/abrasive substances. It operates on the peristaltic principle, using sequential compression of a flexible hose to move material without needing valves.

Key advantages of hose peristaltic transfer pump:

Valveless Design (Critical):

No Clogging: Unlike piston/screw pumps relying on valves (prone to clogging with agg, fibers, or dry material), the peristaltic pump has no valves. Material moves solely via hose compression/release.

Eliminates Valve Wear: Removes a major wear/failure point present in other pump types.

Handles Difficult Materials: Excels at transferring:

Concrete: Abrasive, fiber-reinforced, large aggregate, high-slump/SCC.

Grouts & Mortars: Cementitious, fine, or coarse.

Slurries & Sludges: Abrasive or viscous.

Simplified Maintenance:

Fewer Wear Parts: Primary wear component is the hose. Simpler than piston/screw pump maintenance.

Dry Running Capability: Can run dry briefly without damage.

Gentle Transfer Action: Minimal shear force preserves material properties.

Sealed System: Reduces spillage and air entrainment.

Self-Priming: Draws material vertically from the source.

Flexible Discharge: Easily routed to the exact transfer point, even in confined spaces.