Hose type concrete pump with mixer

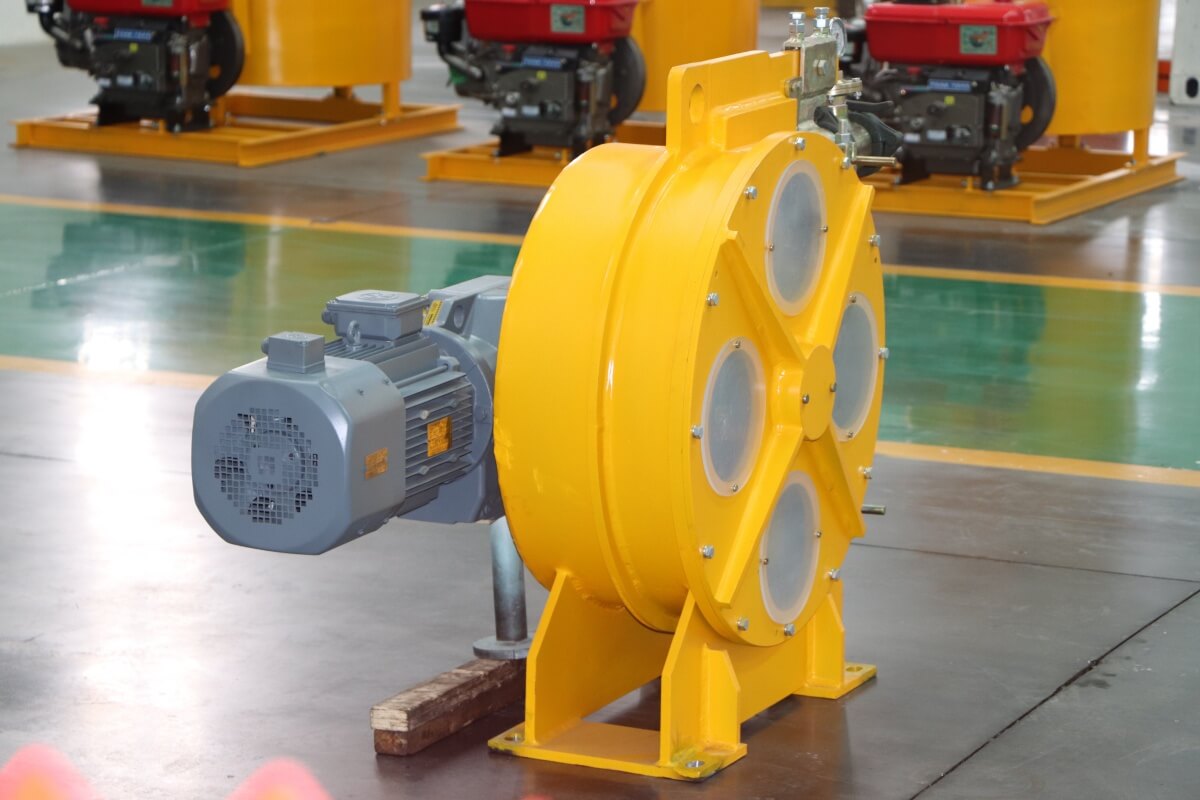

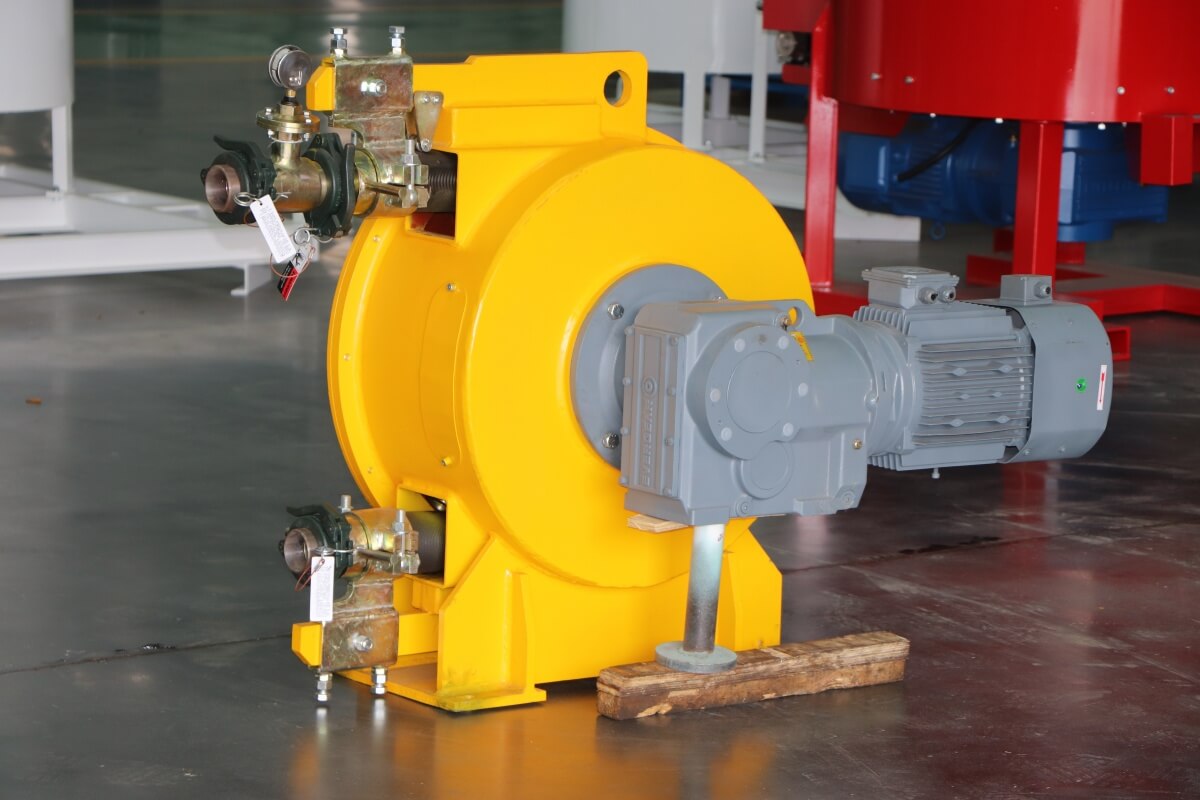

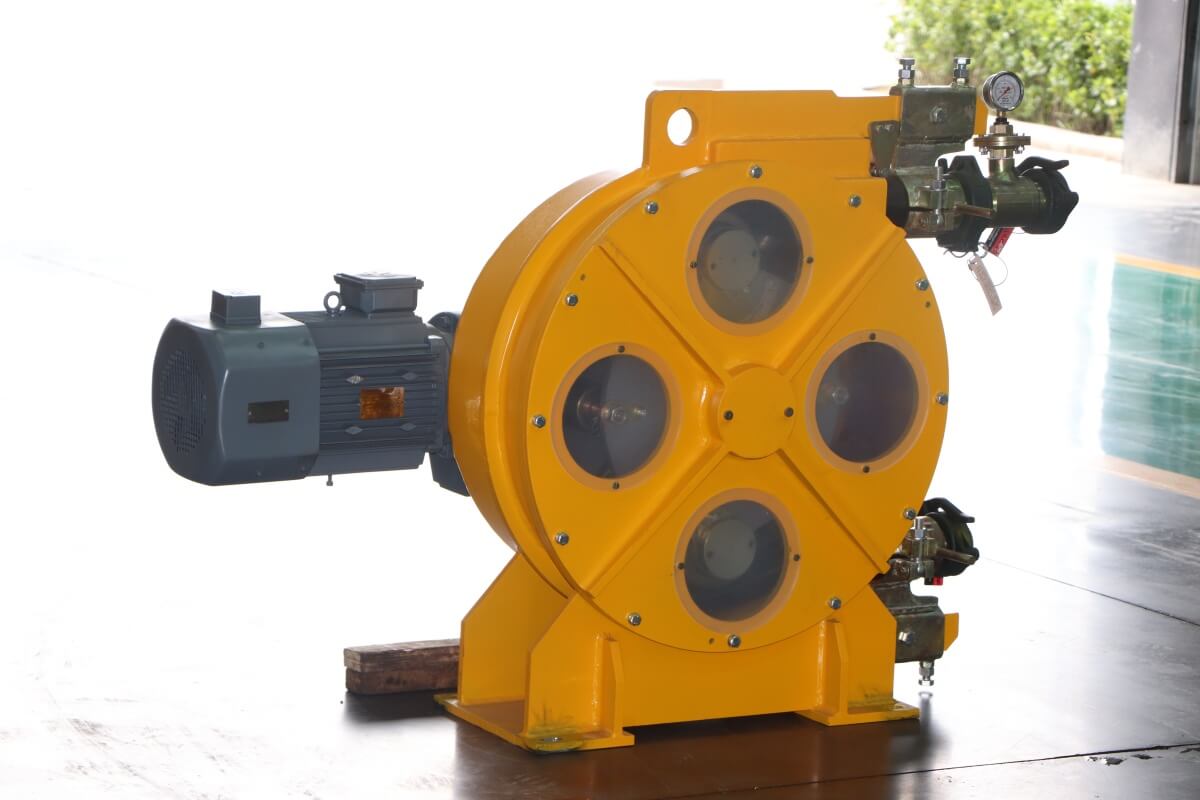

Hose type concrete pump with mixer realizes concrete transportation by squeezing elastic hose with roller or slider, without mechanical seal, avoiding leakage risk. The hose is mostly made of wear-resistant rubber or steel wire reinforcement layer, with a service life of up to 3000-5000m³ (depending on working conditions).

Hose type concrete pump with mixer is equipped with a forced mixing device, which can mix concrete (such as cement, sand, additives, etc.) on site to ensure material uniformity and avoid segregation. The mixed concrete is directly pumped to reduce the transfer process.

Hose type concrete pump with mixer features:

Efficient integration:

The integrated design of mixing and pumping reduces equipment transfer time and improves construction continuity.

Example: A commercial complex project uses the DJBT40 model to complete the underground continuous wall pouring through hose pumping, reducing labor costs by 30%.

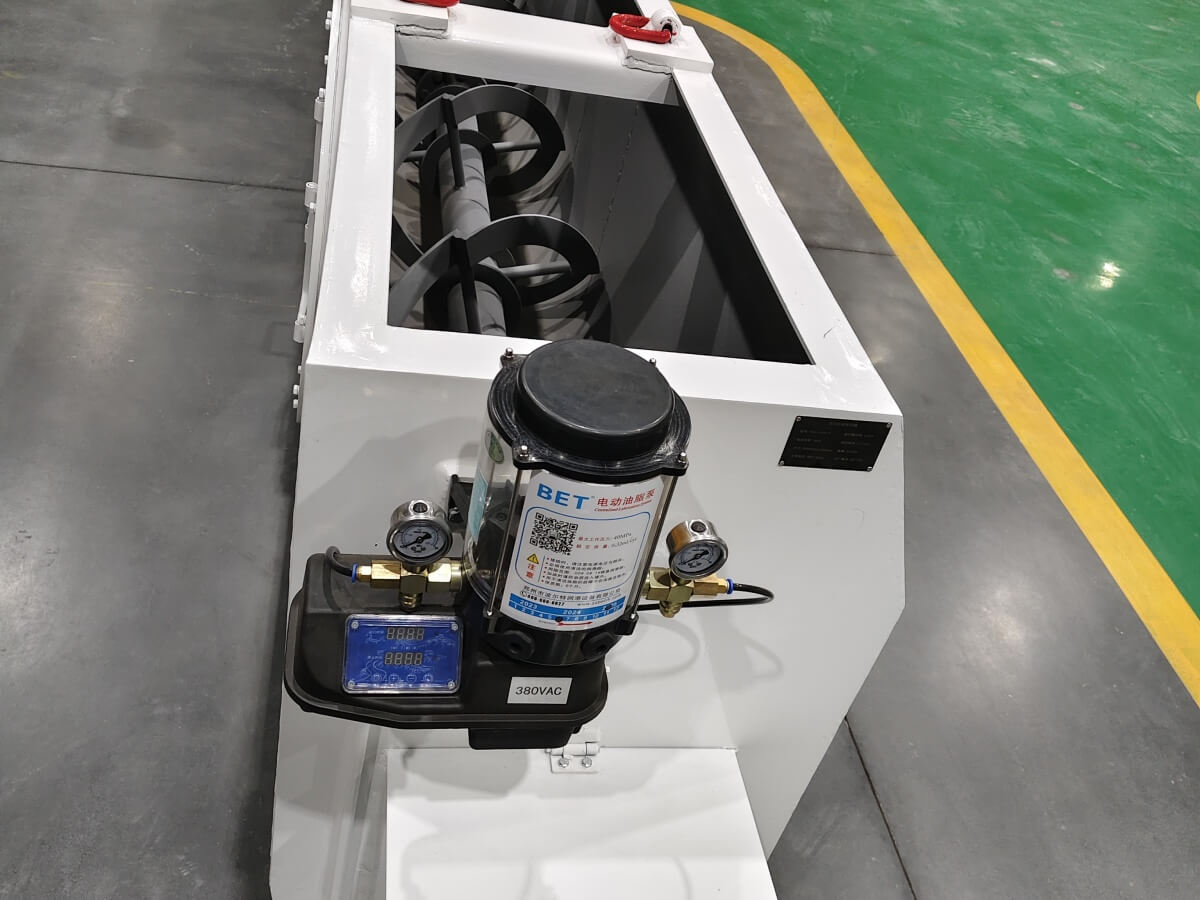

Low maintenance cost:

Only the hose is a consumable part with a long replacement cycle (up to 3000m³ or more depending on the working conditions).

The side guide roller-free design (such as the Konap KNP50 model) avoids hose cutting and extends service life.

High adaptability:

It can transport materials containing solid particles (maximum particle size <1/4 of the hose inner diameter), high viscosity, and shear-sensitive materials.

The flow rate is stable, and the re-measured volume accuracy is ±1%, which supports laboratory-level measurement needs.

Environmental protection and safety:

No leakage risk, in line with the strict standards of the chemical and food industries.

Overpressure/overheating dual protection system ensures safe operation of the equipment.