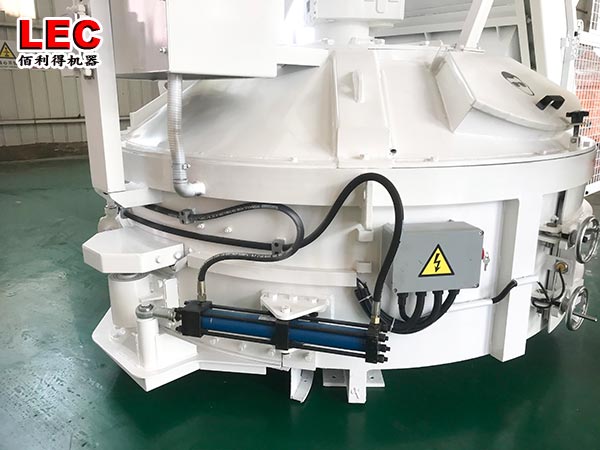

Planetary Mixer/Planetary Mixer Large Mixing Machine

Planetary Mixer is a large mixing machine that meets European CE standards. When compared to the old type, it improves mixing efficiency.

Planetary Mixers can mix all types of high-quality, high-performance concrete and can achieve homogeneous mixing in the lowest amount of time. The planetary mixer is ideal for mixing concrete and refractory materials.

The planetary concrete mixer’s uniquely built gearbox (patented technology) can transmit power to each mixing device in a balanced and effective manner. Even in the most demanding production environments, the mixer can maintain excellent efficiency and low noise levels. While reducing space, the mixer maintenance space has expanded by 30% as compared to the typical gearbox.

The concrete mixer’s carefully designed gearbox (patented technology) can deliver power to each mixing device in a balanced and effective manner. Even in the most demanding production environments, the mixer can maintain excellent efficiency and low noise levels. While reducing space, the mixer maintenance space has expanded by 30% as compared to the typical gearbox.