Home » Planetary concrete mixer » Planetary Mixer for Refractory Brick Machine Production

Planetary Mixer for Refractory Brick Machine Production

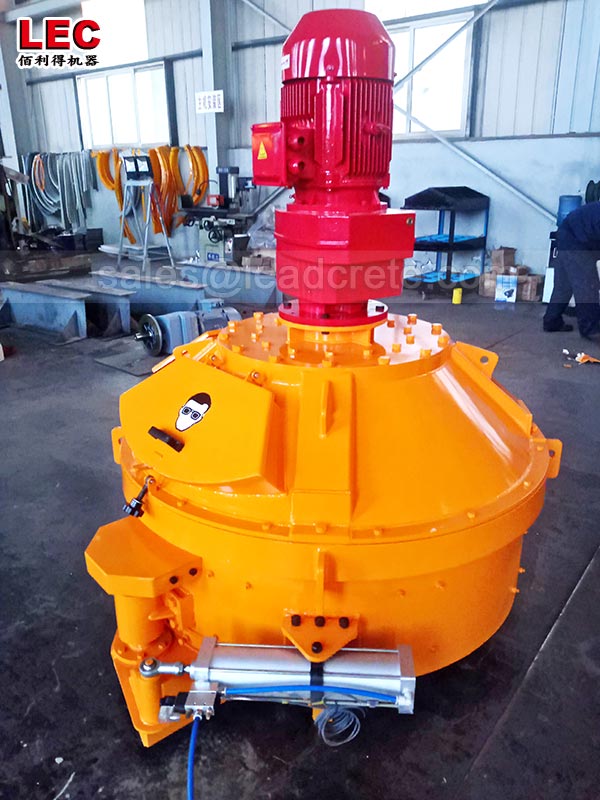

The planetary mixer used in the manufacture of refractory brick machines is simple to maintain and does not have a shaft end leakage issue.

Contact Us

Get Price

Share:

Content 2022-07-09

Features of

planetary mixer for manufacturing refractory brick machines: Stable Motoring. A hard surface gearbox is used to transmit power.High Efficiency of Mixing. The gear box moves the mixing arms along a complicated track, and the mixer performs better if the mixing is turbulent.

Homogenous blending. Multiple groups of mixing arms make up mixing blades, which span the entire mixing area. The homogeneity of the substance is guaranteed by both the revolution and rotation of the mixing blades. The motion track of the mixing blades eventually spans the entire drum, as seen in the image.

Inquiry

More Planetary concrete mixer