Home » Planetary concrete mixer » New vertical shaft cement mixer

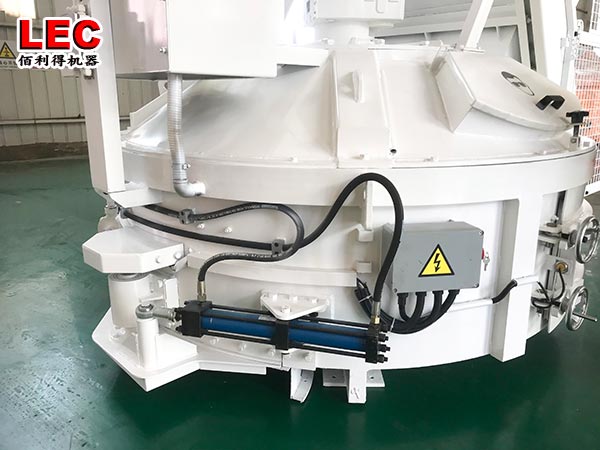

New vertical shaft cement mixer

The new vertical shaft cement mixer is perfect for 2-3 persons construction crew. Why go through all the hassles of towing a mixer to the job site, when the machine can make a wheelbarrow of mortar, stucco, grout or dry pack mortar every 3 minutes.

Contact Us

Get Price

Share:

Content 2021-11-08

New vertical shaft cement mixer can mix all kinds of concrete, meeting many requirement.

Alternative parts has long life, easily to repair and operate and so on, feeding height can be desinged according to customer’s needed.

New vertical shaft cement mixer can be applied with concrete mixer transport machine and dumping car, working with concrete dosing machine.

New vertical shaft cement mixer is a very good option for all kinds concrete mixing projects.

Inquiry

More Planetary concrete mixer