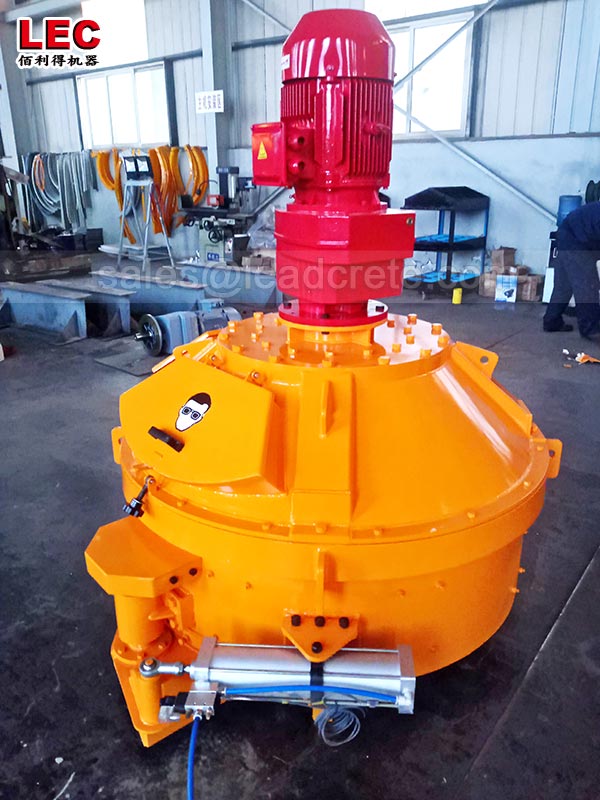

One cbm concrete mixer

Our company is a professional manufacturer and supplier of one cbm concrete mixer.

The one cbm concrete mixer produced are the ideal models for advanced construction equipment at home and abroad. The plates and blades have a long service life and are easy to maintain. It is suitable for mixing plastic, dry, lightweight aggregate concrete and various mortars and mortars.

The shaft of the one cbm concrete mixer produced by us is connected with the transmission mechanism and driven by the transmission mechanism roller. The roller is sleeved around the cylinder gear ring and meshes with the gear ring on the shaft. The utility model has a simple and reasonable structure, and can overcome the sliding phenomenon between the drum and the mixer when the gear and the ring gear mesh. The drive mechanism can further ensure the elimination of the drum between the drum and the mixer.