Home » Planetary concrete mixer » 50kg concrete mixer

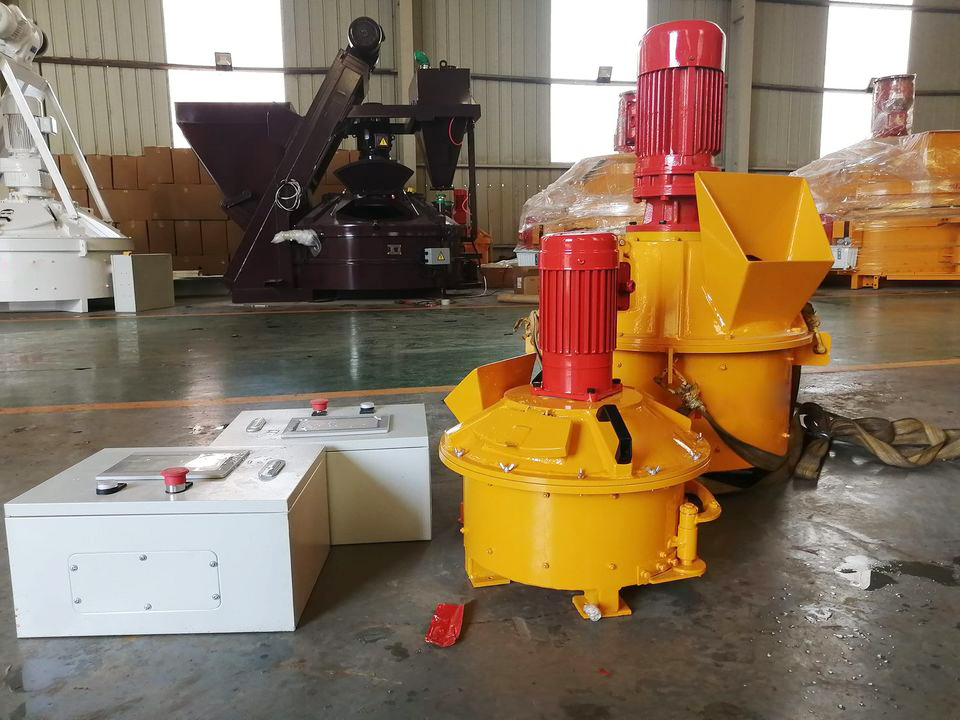

50kg concrete mixer

50kg concrete mixer is a new type of concrete mixer, suitable for general highways, power stations, dam construction, construction sites, roads, bridges, hydropower, and large and medium-sized prefabricated plants and other projects.

Contact Us

Get Price

Share:

Previous:

1000l vertical planetary concrete mixer

Content 2021-11-05

50kg concrete mixer has many advantages, such as stable operation, low energy consumption, compact structure, reliable transmission, important light, high production efficiency.

Our 50kg concrete mixer could mix all type of construction material, such as the cement mortar, concrete on building and dry-mixer mortar, fodder and seed for agriculture, etc. Any interest or information needed, welcome to contact us at sales@leadcrete.com

Inquiry

More Planetary concrete mixer