Planetary concrete mixer for concrete prefabricated panels

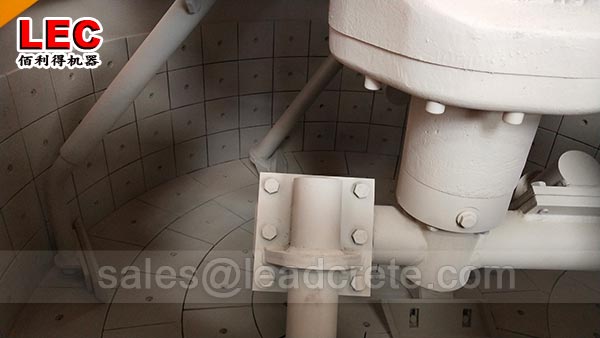

On the Planetary concrete mixer for concrete prefabricated panels assembly, the gearbox assembly consists of a box body, a helical gear, two driven bevel gears and corresponding drive shafts, and the driven gear shaft is connected to the planetary concrete mixer assembly on the planetary plate.

Planetary concrete mixer for concrete prefabricated panels, including mixer body, mixing drum assembly, planetary disc assembly, gear box assembly, lifting assembly and bracket, the bottom of the mixer body is equipped with a bracket, the top of the bracket is equipped with a mixing drum assembly, and the top of the mixing drum assembly is equipped with a disc assembly , the top of the disc assembly is equipped with a gearbox, there are elevator assemblies on both sides of the mixer body, the mixing barrel assembly is made of glass or ceramic plate mixing walls, the bottom of the barrel assembly is provided with a feeding port, and the planetary disk assembly is installed on the gearbox assembly of the gearbox.