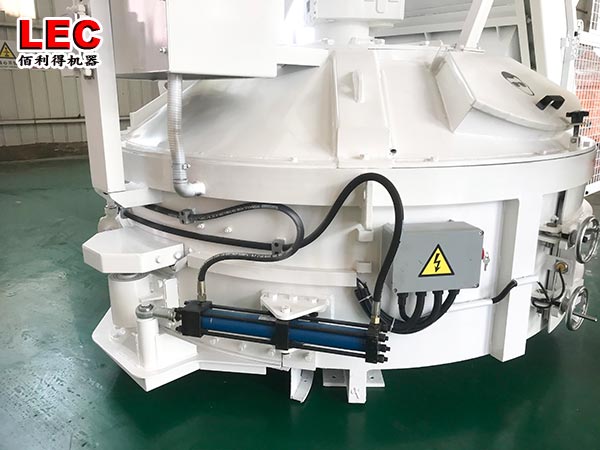

counter current planetary mixer for color

The emergence of counter current planetary mixer for color has contributed to the production of uhpc. As professional equipment, the planetary uhpc mixer has a new structure design, and a special device is designed according to the uhpc production conditions, which makes the mixing performance more powerful and the homogeneity is good. , the stirring efficiency is higher.

Counter current planetary mixer for color meets the needs of high-quality and difficult mixing conditions for the use of mixers. Homogeneous mixing, mixing speed, and mixing cycle meet user standards. The counter current planetary mixer for color disperses the aggregated cement mass without damaging the aggregate particles of the mixture, with stable stirring and high efficiency.