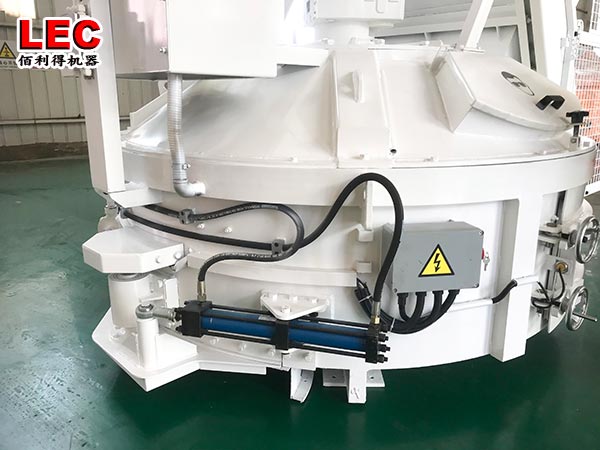

Concrete planetary mixer for glass building material

Leadcrete Equipment offers high-quality best fast concrete planetary mixer for glass building material, our company is a successful concrete planetary mixer supplier and manufacturer from China.

The concrete planetary mixer has a leading advantage in the characteristic direction of high-quality mass production. The concrete planetary mixer for glass building material is especially suitable for the production line, with no difference in batch production, low failure rate, and low application cost.

The concrete planetary mixer for glass building material is of good quality, selected high-quality plates, selected excellent components, and rigorous equipment production process to make the industry’s vertical shaft mixer model equipment. The price of the vertical concrete mixer is fair. Although it is not the lowest price in the industry, the mixer is excellent value for money.

The concrete planetary mixer for glass building material is easy to operate and use, and the application can improve the efficiency to a greater extent. The concrete planetary mixer for glass building material has also been upgraded in terms of environmental protection and dust removal. It is equipped with reliable sealing and dust removal and is also convenient for maintenance and use.