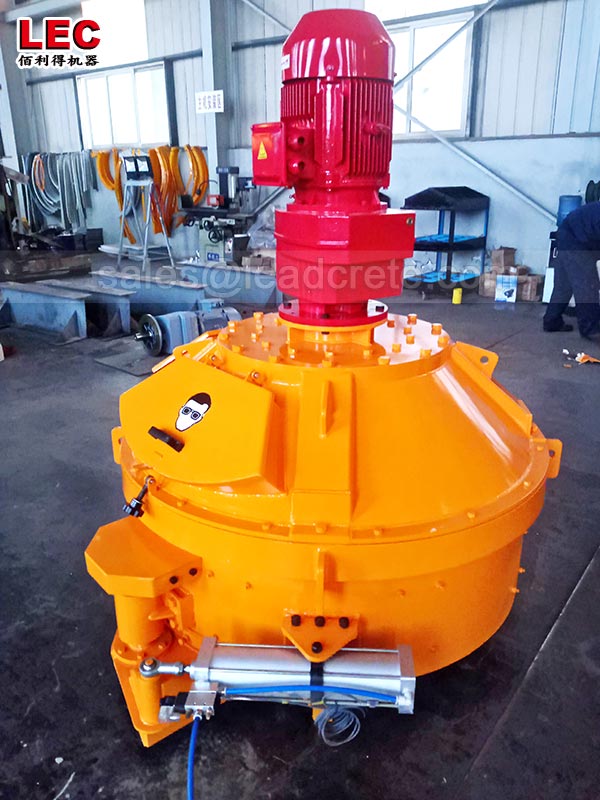

Self loading planetary refractory mixer

If you want to build a concrete mixing plant for the production of prefabricated components and want to know how much to invest in a self loading planetary refractory concrete mixer, you can consult us for a quote.

The advanced processing technology, rigorous structural configuration and flexible processing methods of the vertical shaft planetary mixer have laid a strong foundation for processing various refractory materials. The new process direction of the vertical shaft refractory mixer production is to use the advantages of the new planetary mixing to stabilize the uncertain mixing factors generated in the refractory. The rotation and revolution form can largely ensure that the planetary operation will bring high strength to the production material. The mechanical force guarantees the production effect of high homogeneity. The wear-resistant treatment method of the vertical shaft planetary self loading concrete mixer is developed for the production characteristics of refractory materials. According to the complex ratio of refractory materials and production conditions, the durable performance of the equipment is continuously improved to ensure that the equipment can continuously and stably play the equipment. The advantages of production, balance the material quality of production engineering.