Home » Planetary concrete mixer » Counter Current Planetary Mixer Manufacturer

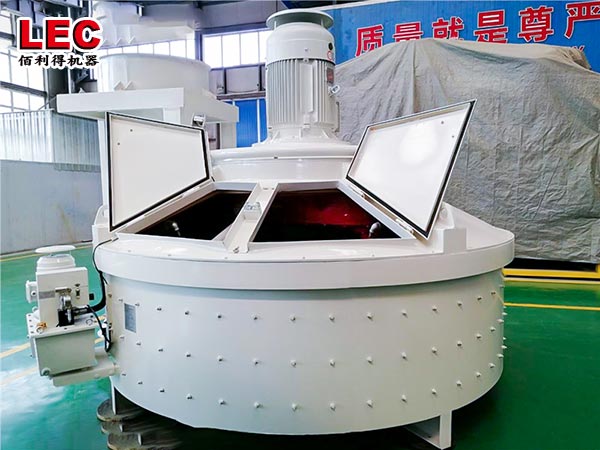

Counter Current Planetary Mixer Manufacturer

We can serve you with high quality planetary concrete mixers at factory prices as a counter current planetary mixer manufacturer.

Contact Us

Get Price

Share:

Content 2022-06-16

Leadcrete has the most modern technologies as the leading enterprise in the European mixing sector. One of Leadcrete’s main products is a counter current planetary mixer. With its unique heavy-duty gearbox, fresh prospective design, high-quality components, and excellent mixing performance, it wins the favor of European clients.

Customers from Europe and Southeast Asia agree that employing factory supply planetary concrete mixer factory can not only increase mixing quality but also save cement consumption after years of comparison through practical applications.

Inquiry

More Planetary concrete mixer