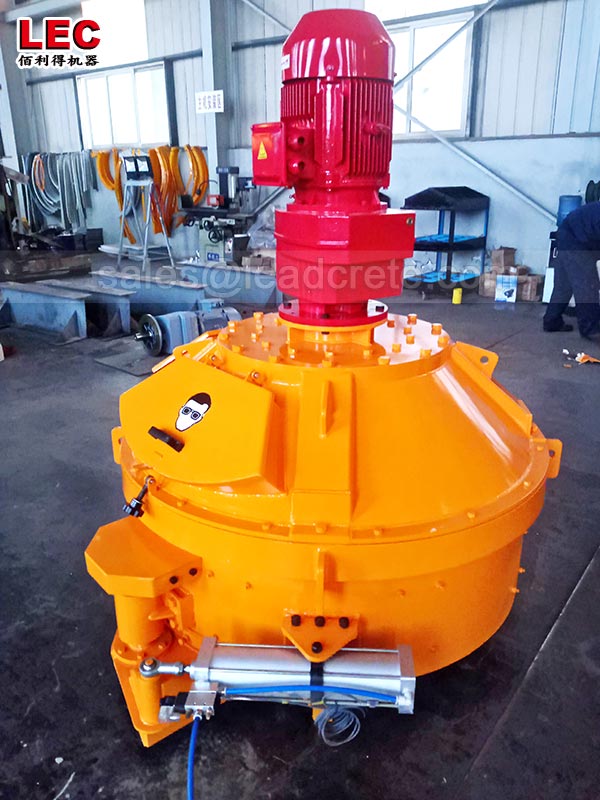

Planetary Concrete Cement Truck and Pan Mixer

An integrated two-way mixing reducer and full oil bath lubrication are used in the Planetary Concrete Cement Truck and Pan Mixer. The equipment can be made to execute planetary mixing with the help of this reducer.

Through the planetary mixing track, the Planetary Concrete Cement Truck and Pan Mixer can achieve good mixing and mixing performance, and the equipment can perform dispersive and distribution mixing.

Planetary Concrete Cement Truck and Pan Mixer’s mixing time and equipment mixing strength can be easily changed according to the real working conditions until the mixing quality criteria are reached, and the mixing state of the mixed ingredients can be visually examined throughout the mixing operation.

The Planetary Concrete Cement Truck and Pan Mixer uses a single motor drive mode, which effectively eliminates output asynchrony. This means that no matter what type of Planetary Concrete Cement Truck and Pan Mixer production line is used, there will be enough production line layout space, the equipment will be beautiful, and the space will be clear.