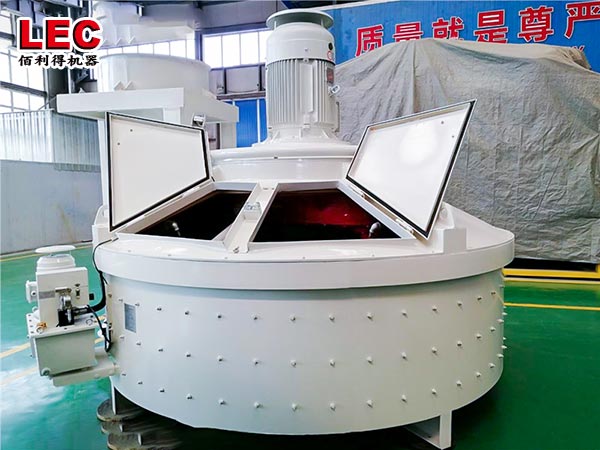

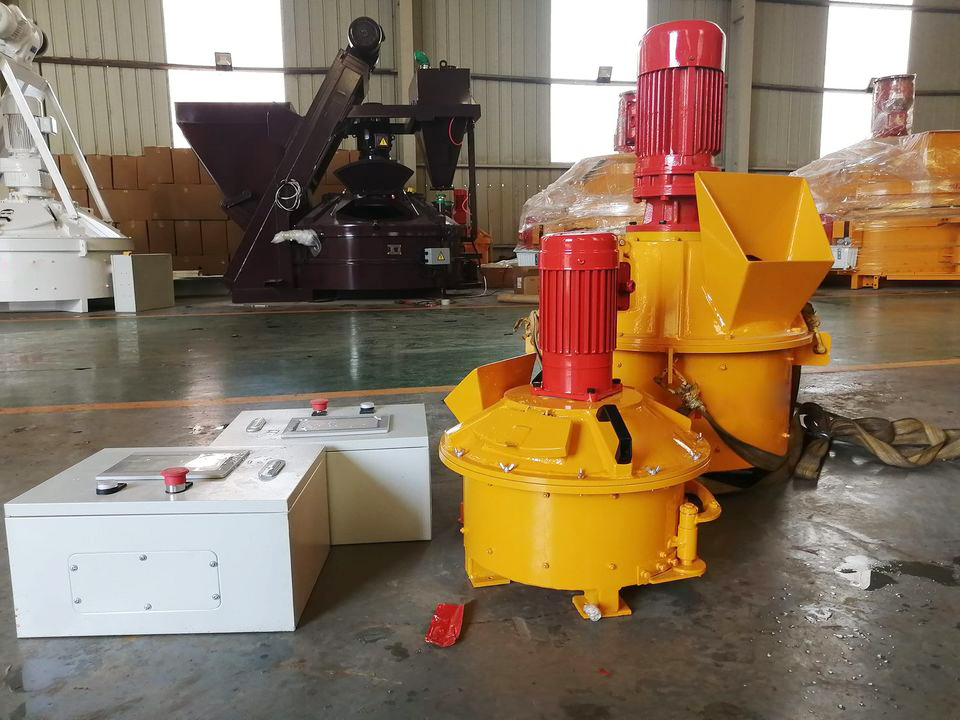

High efficiency brick mixer machine

High efficiency brick mixer machine in China can use for UHPC wall products and big construction projects, like bridge construction.

As a professional high efficiency brick mixer machine manufacturer, we provides the following products: high efficiency brick mixer machine, stationary concrete batching plant, mobile concrete batching plant, concrete mixer, aggregate batch machine, cement silo, screw conveyor, stabilized soil mixing plant, mortar mixer, asphalt mixing plant, concrete truck, self loading concrete truck, and concrete pump, wheel loader, tower crane, construction lift, brick making machine, etc.

High efficiency brick mixer machine can mix all kinds of high-quality and high-performance concrete, and which can reach homogenious mixing at shortest time. The mixing effect is better, this is called planetary mixing, 360 degrees without dead angle, several grades higher than the disc mixer.