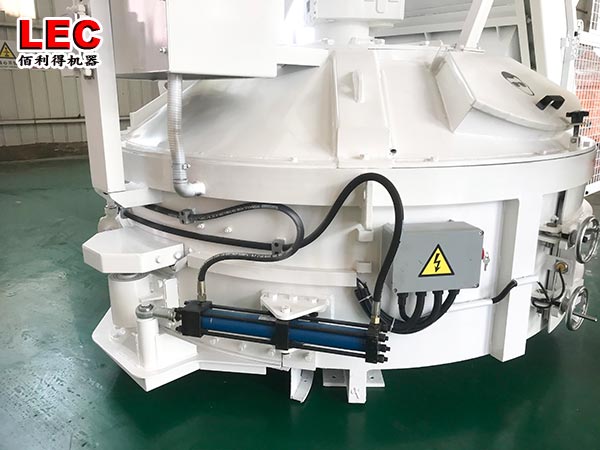

Factory self loading concrete mixer

Featured factory self loading concrete mixer have been exported to Vietnam, Kazakhstan, Pakistan, Russia, Ukraine, Brazil etc.

Leadcrete Equipment is a professional manufacturer of factory self loading concrete mixer machinery. We has 12 advanced production lines covering almost all kinds of factory self loading concrete mixer used for construction engineering, such as asphalt mixing plant, concrete batching plant and asphalt distributor.

We values “Honesty, Keeping Promise, Good Quality”, which wins us a high reputation home and abroad. We are sincerely looking forward to cooperation and establishing business relationship with enterprises globally. If interested in any of our factory self loading concrete mixer, please send us your inquiry, we will respond you as soon as possible.