Planetary Mixers UHPC Concrete

Planetary Mixers UHPC Concrete

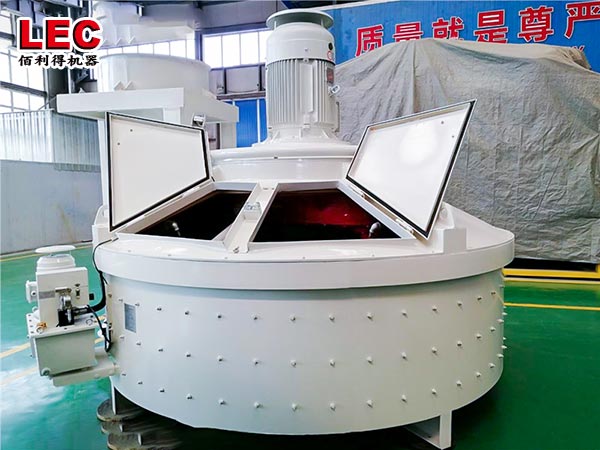

Our company was established in 2012 and has many years of mature experience in producing and selling products. Planetary Mixers UHPC Concrete is one of excellent products in our company, we can provide different models of this type of products according to customer requirements. Planetary Mixers UHPC Concrete is a new type of mixing and stirring equipment, suitable for a variety of high viscosity and high solid materials.

Planetary Mixers UHPC Concrete has a unique and novel form of mixing, the kettle has two or three multi-layer slurry blade stirrer and 1 to 2 automatic scraper, the stirrer in the axis of the kettle body while rotating around its own axis at different speeds, high-speed rotation, so that the material in the body of the kettle for complex movement, subject to strong shear and rub together its efficiency is usually several times that of ordinary mixers.

The characteristics of Planetary Mixers UHPC Concrete are: the main machine adopts planetary gear reducer design, low noise, high mechanical efficiency, which can save power and reduce the space occupied by the equipment.

The machine is suitable for mixing, reacting, dispersing, dissolving, tempering and other processes of multi-component solid-solid phase, solid-liquid phase, liquid-liquid phase materials required in chemical, light industry, food, battery, pharmaceutical, building materials, pesticide and other industries, such as ink, pigment, adhesive, sealant, encapsulating adhesive ointment, paste materials, grease, paint, paste cosmetics, additives and other high viscosity preparation. The viscosity range is from 10,000 to 1,000,000 CP. The form of stirrer can be multi-layer blade type, frame type, butterfly type, external wheel type, etc. according to the material requirements.