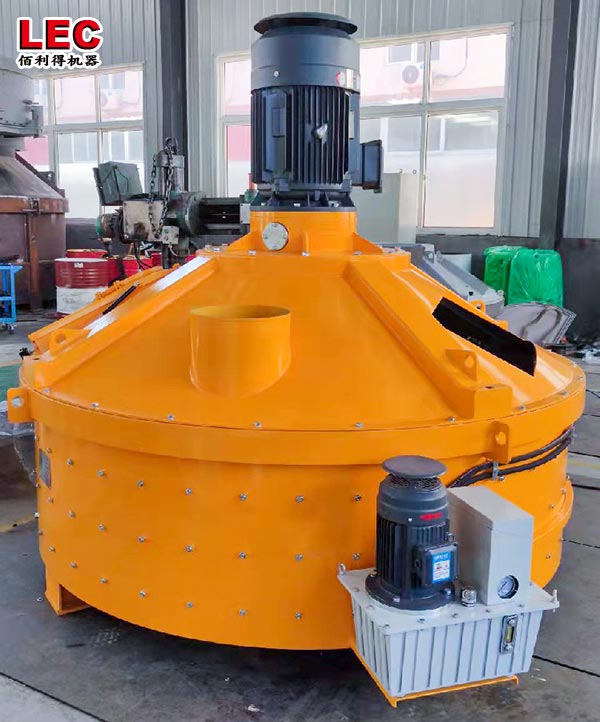

Planetary mixer for glass batching powder mixing machine

Planetary mixer for glass batching powder mixing machine comes with intelligent use, which is more reflected in equipment maintenance. The mixer saves labor in refueling and automatic cleaning and improves processing accuracy. Planetary mixer for glass batching powder mixing machine In order to ensure the service life of the equipment, for different types of glass raw materials, the equipment provides a variety of options for material application to ensure the durability of the equipment.

Planetary mixer for glass batching powder mixing machine complex mixing trajectories overlap each other without omission, zero dead angles, combined with suitable mixing speed so that the mixing material is violently processed to form a high-uniform processing quality material.

Planetary mixer for glass batching powder mixing machine is highly superior in structural design, which fundamentally determines the durability of the equipment. The vertical axis counter-current planetary mixer has less daily maintenance content and fewer equipment failures. It can improve productivity when used in various production lines efficiency and improve production quality.