Planetary concrete pan mixer machine for sale

The planetary concrete pan mixer machine for sale forms the effect of mixing and granulating through repeated cycles. The planetary concrete pan mixer machine for sale is full of power, the effect is obvious, and the comprehensive use is good. The improvement of wear resistance and corrosion resistance effectively reduces equipment damage and saves various production costs.

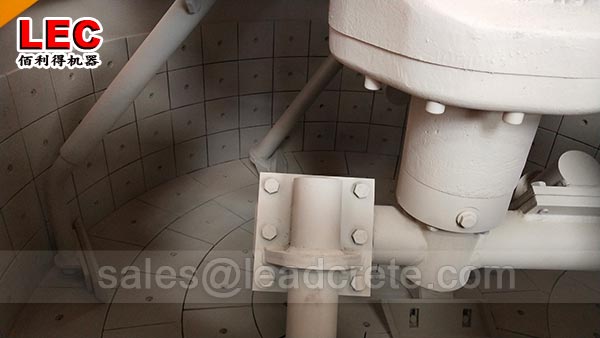

During the mixing process of the planetary concrete pan mixer machine for sale, the rotating material barrel will generate a strong shearing force to bring the material to the top of the planetary concrete pan mixer machine for sale. At the same time, the planetary concrete pan mixer machine for sale continuously performs various processes such as mixing, shearing, and separating. The material is peeled from the inner wall by the scraper and falls down. The material is subjected to the dual action of gravity and mechanical force during the mixing process.