Home » Planetary concrete mixer » High Output Vertical Shaft Planetary Refractory Mixer for Concrete Block Making Machine Plant

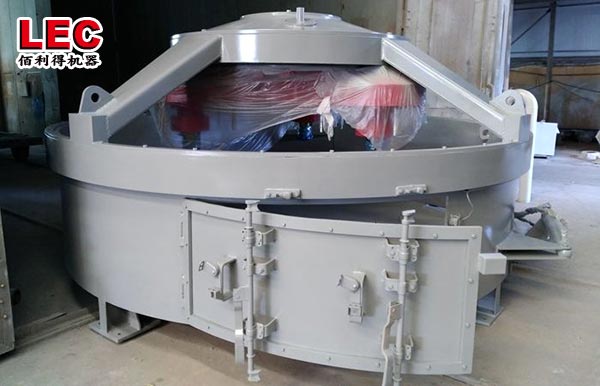

High Output Vertical Shaft Planetary Refractory Mixer for Concrete Block Making Machine Plant

It is well known that High Output Vertical Shaft Planetary Refractory Mixer has a strong processing capacity for Concrete Block Making Machine Plant, so for various types of block raw material mixing, the Vertical Shaft Planetary Refractory Mixer is really much easier to handle.

Contact Us

Get Price

Share:

Content 2022-06-15

The Vertical Shaft Planetary Refractory Mixer for Concrete Block Making Machine Plant has a unique structure and flexible layout that greatly improves the synchronisation of the entire brick machine production line.

It has a high level of automation, saves time and labour, and produces at a high rate. The vertical axis planetary mixer reduces the number of defective bricks produced and lowers production costs.

Inquiry

More Planetary concrete mixer